Mechanical claw disc for tire

A technology of mechanical claws and tires, which is applied in the field of tire mechanical claws, can solve problems such as tire damage, and achieve the effects of small friction, precise movement, and reduced quality and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

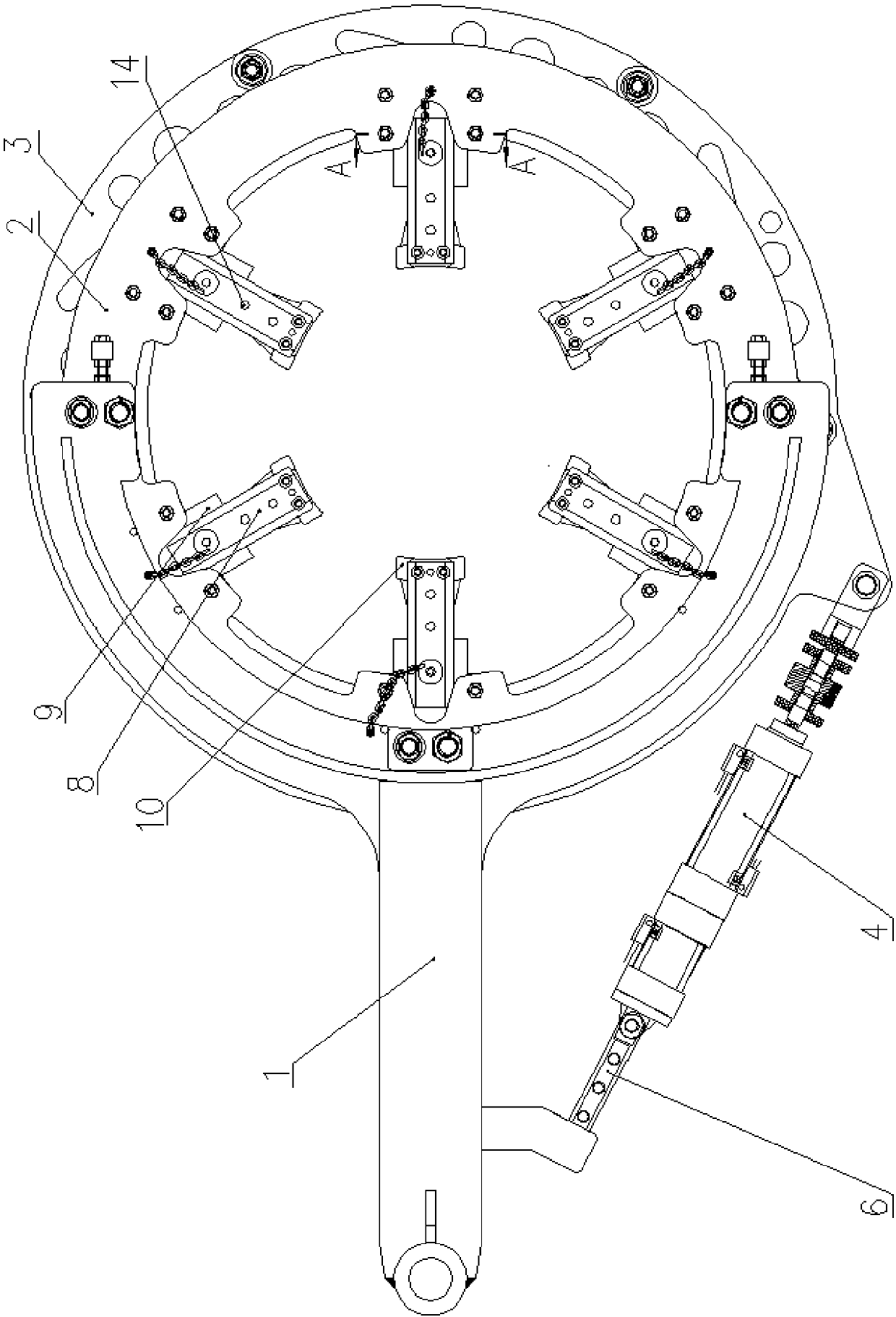

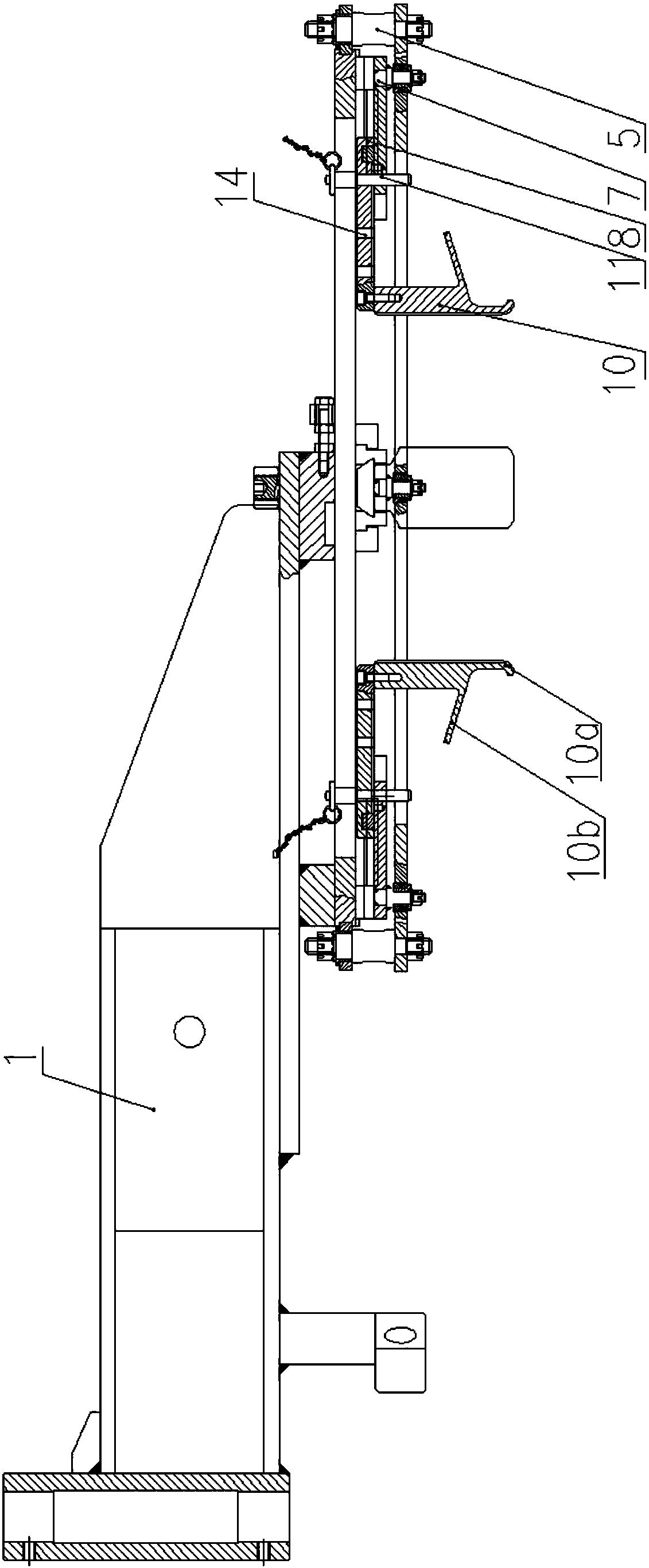

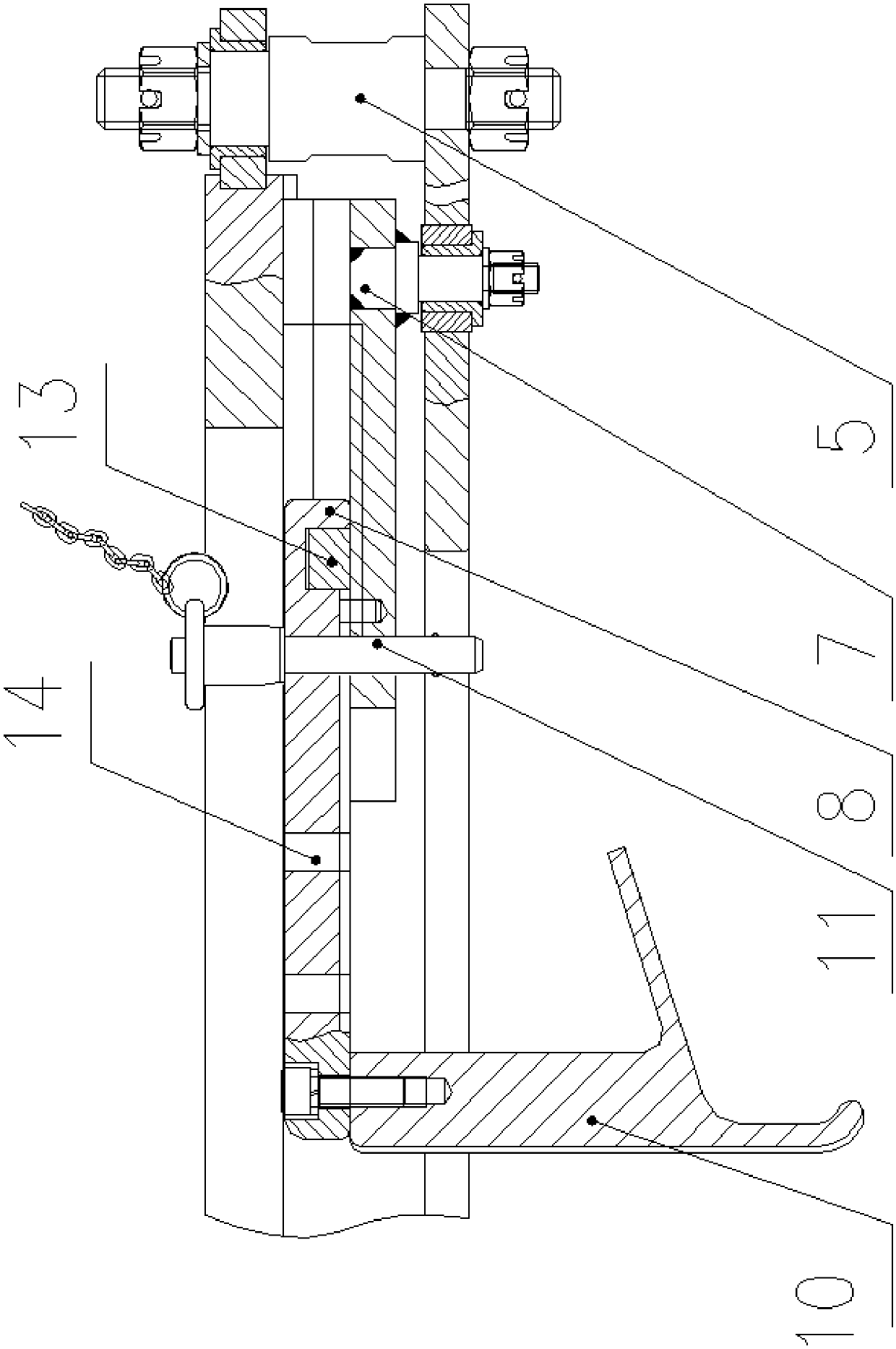

[0035] In order to achieve the purpose of the present invention, a tire mechanical paw plate, comprising: an annular slot plate 3, a number of arc grooves 3a are arranged in an annular array on the slot plate 3; a number of telescopic arms 8 are in an annular array, and only have The degree of freedom of movement in the direction, the telescopic arm 8 is connected with a roller pin 15, and the roller pin 15 cooperates with the arc groove 3a; The grooved plate 3 is radially expandable to clamp or loosen the tire.

[0036] The beneficial effect of adopting the above technical solution is that the tire is grasped, moved and put down through the elastic fit with the inner ring of the tire without damaging the tire tread. The mechanism is used to convert the simple rotary motion output by the equipment into the radial translation motion of the telescopic arm. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com