A stamping and welding process for sheet metal parts

A technology of stamping welding and sheet metal parts, which is applied in the field of sheet metal parts processing, can solve the problems of easy wrinkling of bending rounded corners, cracked four-corner joints, excessive cracks, etc., to avoid wrinkling or even cracking, and to solve problems Wrinkle, the effect of simplifying the stamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described in conjunction with the following examples.

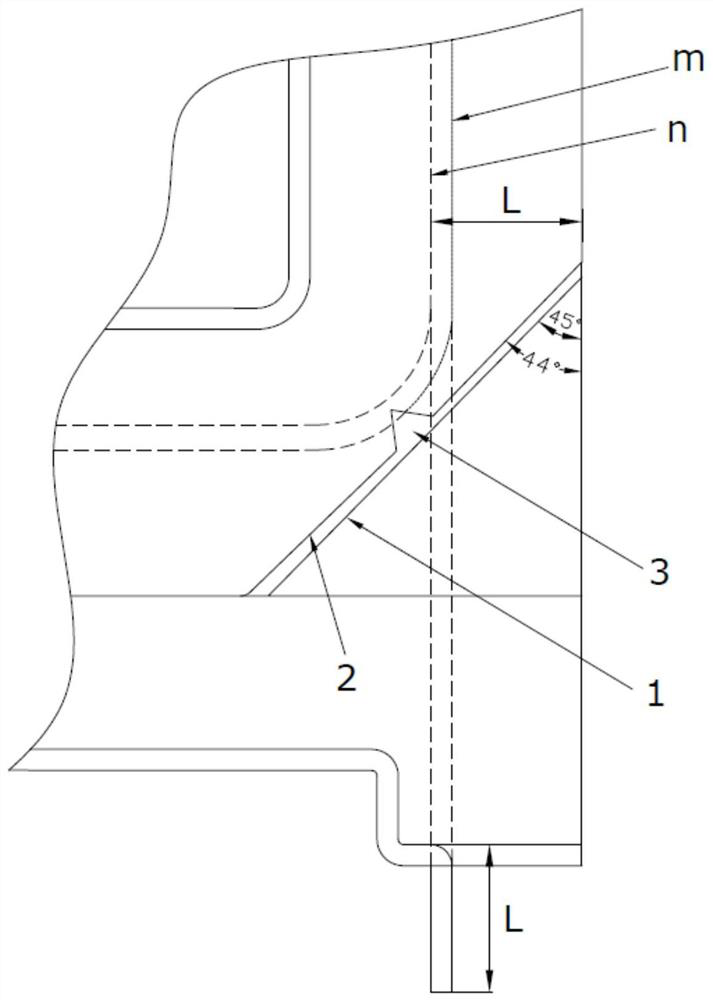

[0034] Such as figure 2 As shown, where: the dotted line n indicates the inner bending line, the dotted line m indicates the outer bending line, and the required bending height at the four corners of the sheet is L.

[0035] A stamping and welding process for sheet metal parts of the present embodiment comprises the following steps:

[0036] Step a, drawing forming:

[0037] Draw and form the sheet as a whole, and initially draw the convex hull at the right angle of the sheet, the initially formed convex hull is hemispherical or ellipsoidal;

[0038] Step b, plastic processing:

[0039] Punch the initially formed sheet to punch out the required process holes and positioning holes; then trim the edge and remove excess waste around the sheet;

[0040] Step c, design of cut corners and V-shaped notch 3:

[0041] According to the bending height required at the four corners of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com