Efficient cutting mechanism for linear guide rail

A linear guide rail and cutting mechanism technology, applied in the direction of shearing devices, shearing equipment, metal processing equipment, etc., can solve the problems of low surface quality of the incision, movement of the rotating shaft, prolonged contact time, etc., and achieve motion stability and moving straight line Good precision, smooth and precise cutting, improving the effect of high temperature problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the drawings in the embodiments.

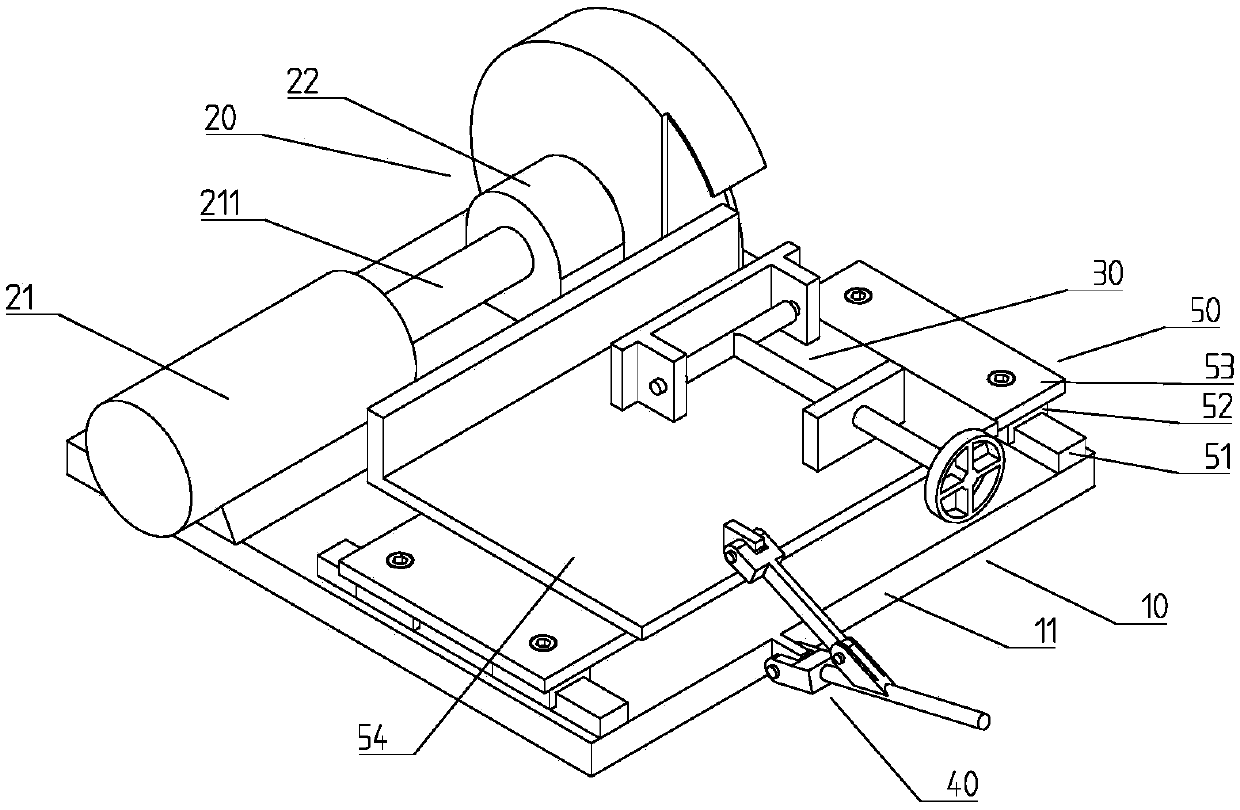

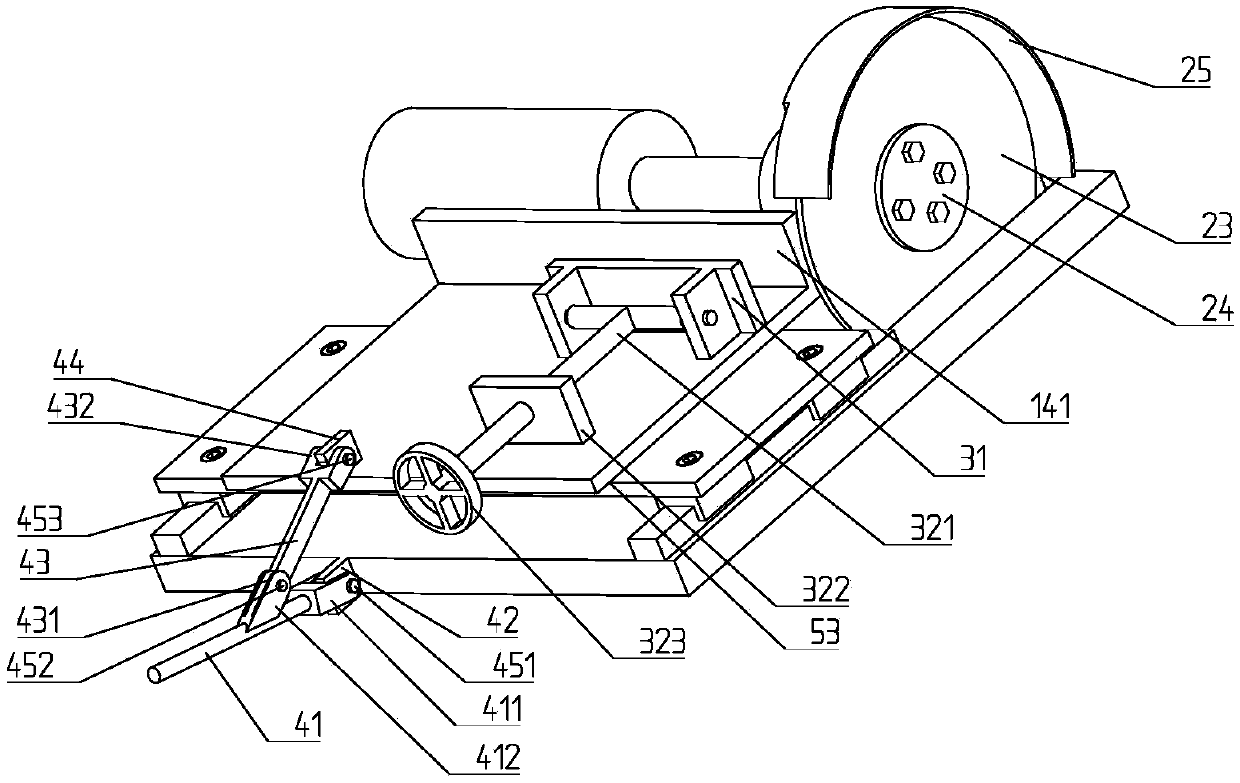

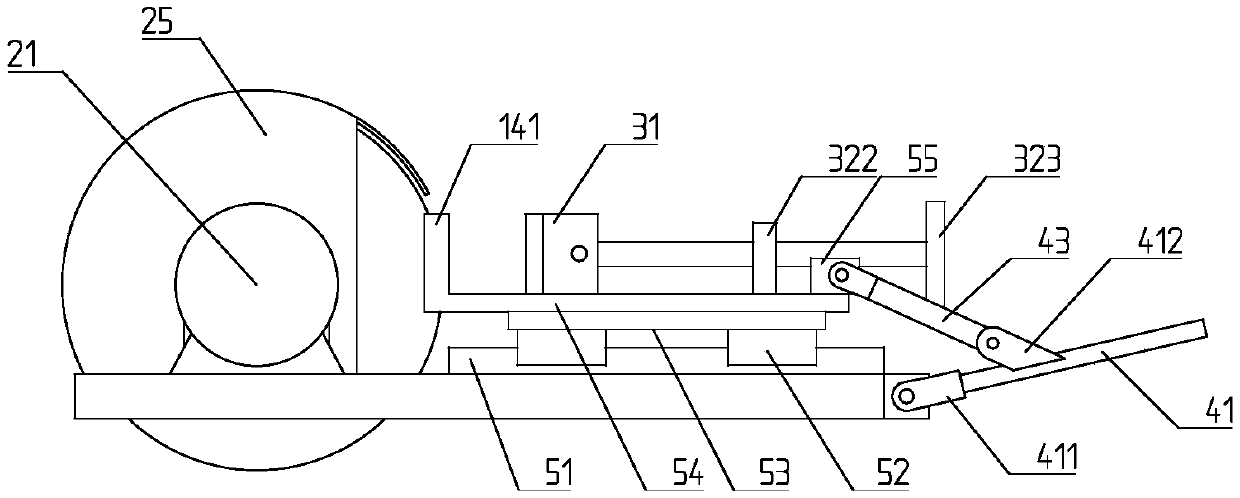

[0022] Linear guide high-efficiency cutting mechanism, including frame 10, cutting assembly 20, clamping mechanism 30, cutting assembly 20 is fixedly installed on frame 10, cutting assembly 20 includes driving motor 21, transmission shaft 211, transmission shaft support 22 and cutting blade 23. It also includes a sliding table assembly 50 and a sliding table driving assembly 40;

[0023] The slide assembly 50 includes a slide rail 51 fixed on the frame 10, a slide block 52 sliding along the slide rail 51, a connecting plate 53 fixed on the slide block 52, and a workbench 54 fixed above the connecting plate 53;

[0024] The clamping mechanism 30 is fixedly installed on the workbench 54, and the cutting piece 23 is perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com