Nitrogen-doped carbon material, and preparation method and application thereof

A nitrogen-doped carbon and nitrogen content technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxidized water/sewage treatment, etc., can solve the complex preparation method of nitrogen-doped carbon materials and the limited ability to degrade organic pollutants , the problem of high cost, to achieve the effect of easy availability, good reactivity, and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a nitrogen-doped carbon material, comprising the following steps:

[0032] (1) Calcining glucose at 700-1100° C., preferably 950-1100° C., particularly preferably 1000° C., for 60-240 minutes, preferably 120-180 minutes, particularly preferably 120 minutes, in a non-oxygen-containing atmosphere to carbonize the glucose (deoxydehydrogenation) to obtain a carbon substrate.

[0033] (2) The carbon substrate obtained in step (1) and melamine are mixed in an aqueous solution according to a mass ratio of 1:(0.5~3), preferably 1:(0.5~1), especially preferably 1:1, and heated and stirred , after drying at 300°C to 700°C, preferably 500°C to 600°C, particularly preferably 550°C under non-oxygen-containing atmosphere conditions; calcining for 60min to 240min, preferably 120min to 240min, particularly preferably 240min, to obtain nitrogen doped carbon material. Non-oxygen atmosphere such as nitrogen, argon or other inert gases.

[0...

Embodiment 1

[0040] An efficient method for preparing nitrogen-doped carbon materials, the method for preparing nitrogen-doped carbon materials in this embodiment includes the following specific steps:

[0041] (1) Preparation of carbon substrate

[0042] Put 10 g of glucose into a tube furnace and calcinate at 1000° C. for 120 min under the protection of nitrogen to obtain a carbon substrate.

[0043] (2) Nitrogen-doped carbon materials

[0044] Mix the material obtained in (1) and melamine in an aqueous solution at a mass ratio of 1:1, then heat and stir, dry and put it in a tube furnace for 240 minutes under the protection of nitrogen at 550°C to obtain nitrogen-doped Carbon material, the nitrogen doping amount of the material is about 2% to 3%.

[0045] Carry out result analysis according to the catalyst prepared by described embodiment:

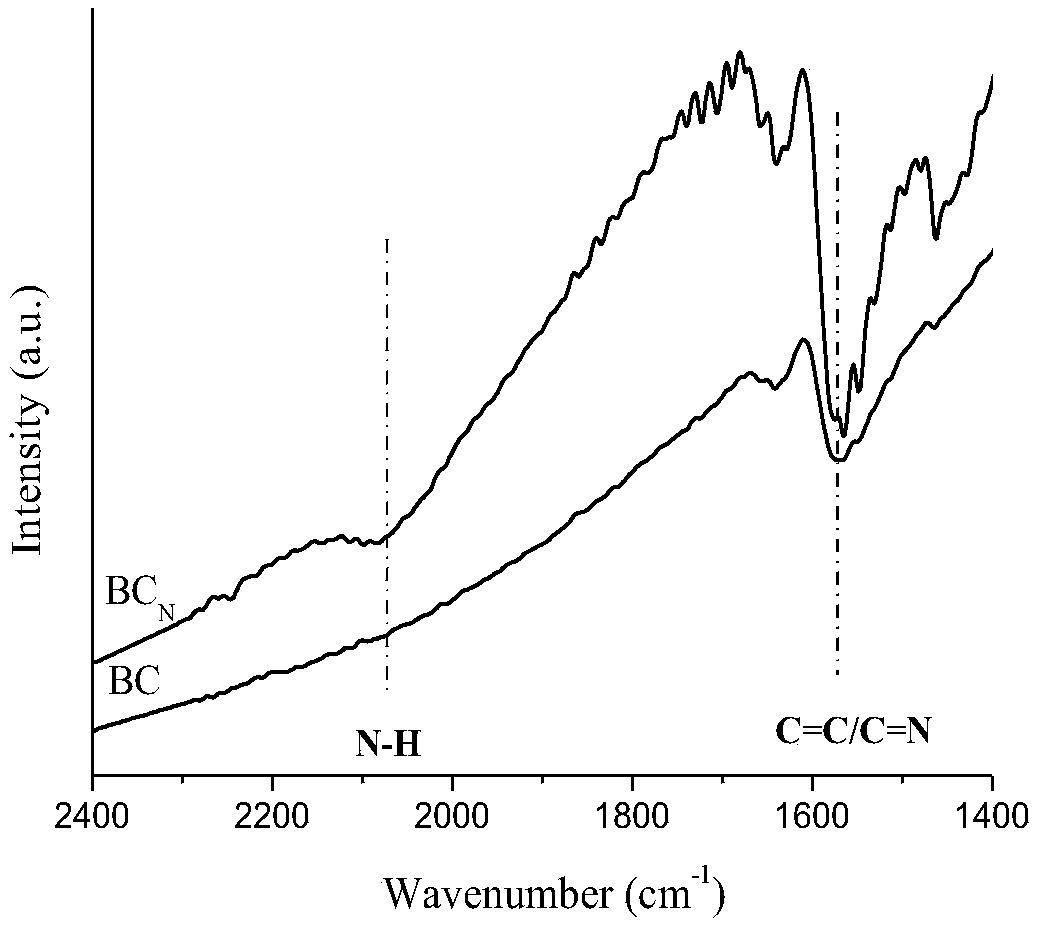

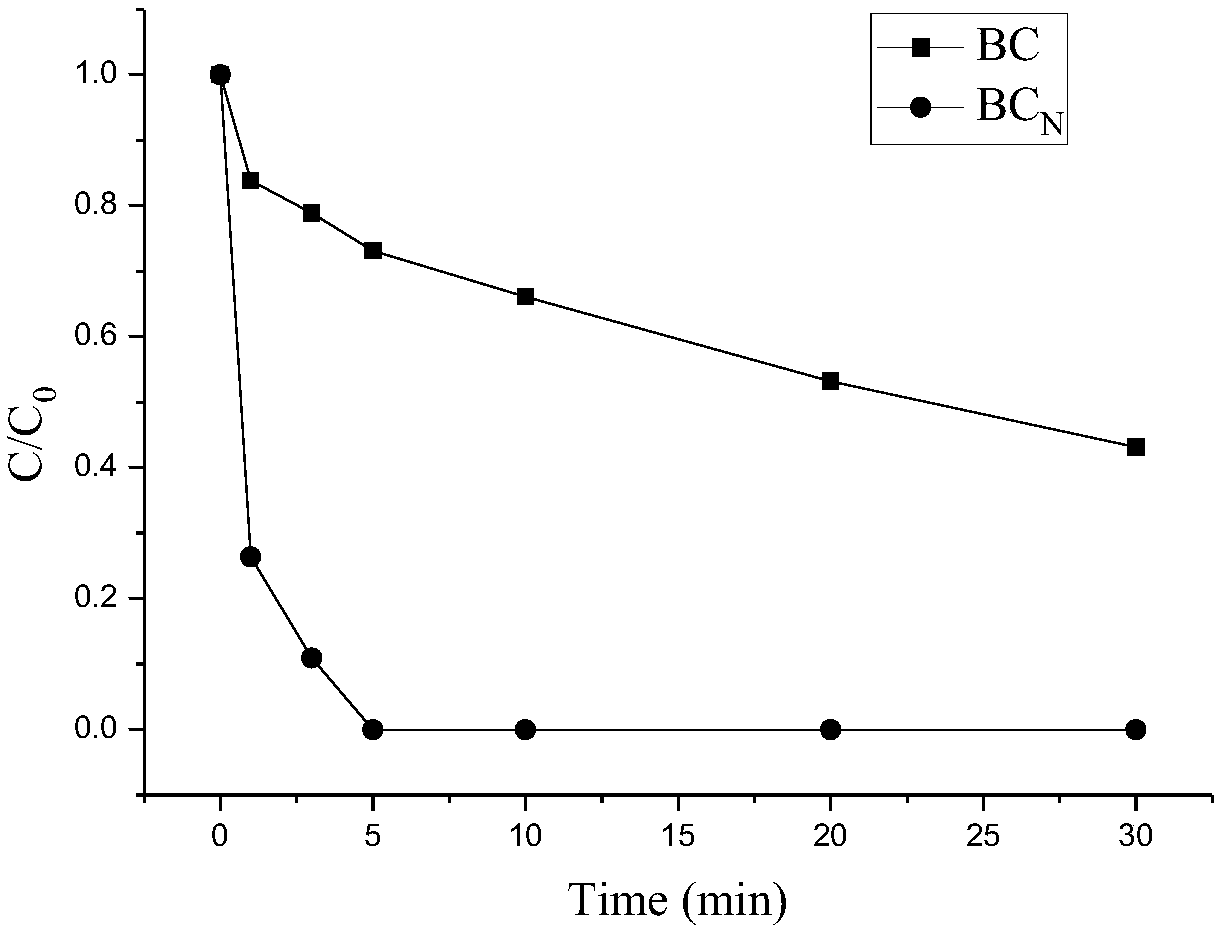

[0046] figure 1 : Infrared spectra of carbon substrates and nitrogen-doped carbon materials

[0047] From the infrared spectrum figure 1 It ca...

Embodiment 2

[0059] (1) Preparation of carbon substrate

[0060] Put 10 g of glucose into a tube furnace and calcinate at 1000° C. for 120 min under the protection of nitrogen to obtain a carbon substrate.

[0061] (2) Nitrogen-doped carbon materials

[0062] The material obtained in (1) and melamine are mixed in the aqueous solution at a mass ratio of 2:1, then heated and stirred, dried, put into a tube furnace and calcined for 240min under the protection of nitrogen at 550°C to prepare nitrogen-doped Carbon material, the nitrogen doping amount of the material is about 0.5%-2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com