Production method of absorbent product with breathable waistline

A technology for absorbent articles and waistlines, which is applied in the field of preparation of absorbent articles with breathable waistlines, can solve problems such as poor comfort, uneven elasticity, and poor air permeability, so as to reduce the use of rubber materials, ensure uniform stretching, and increase wearing comfort sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

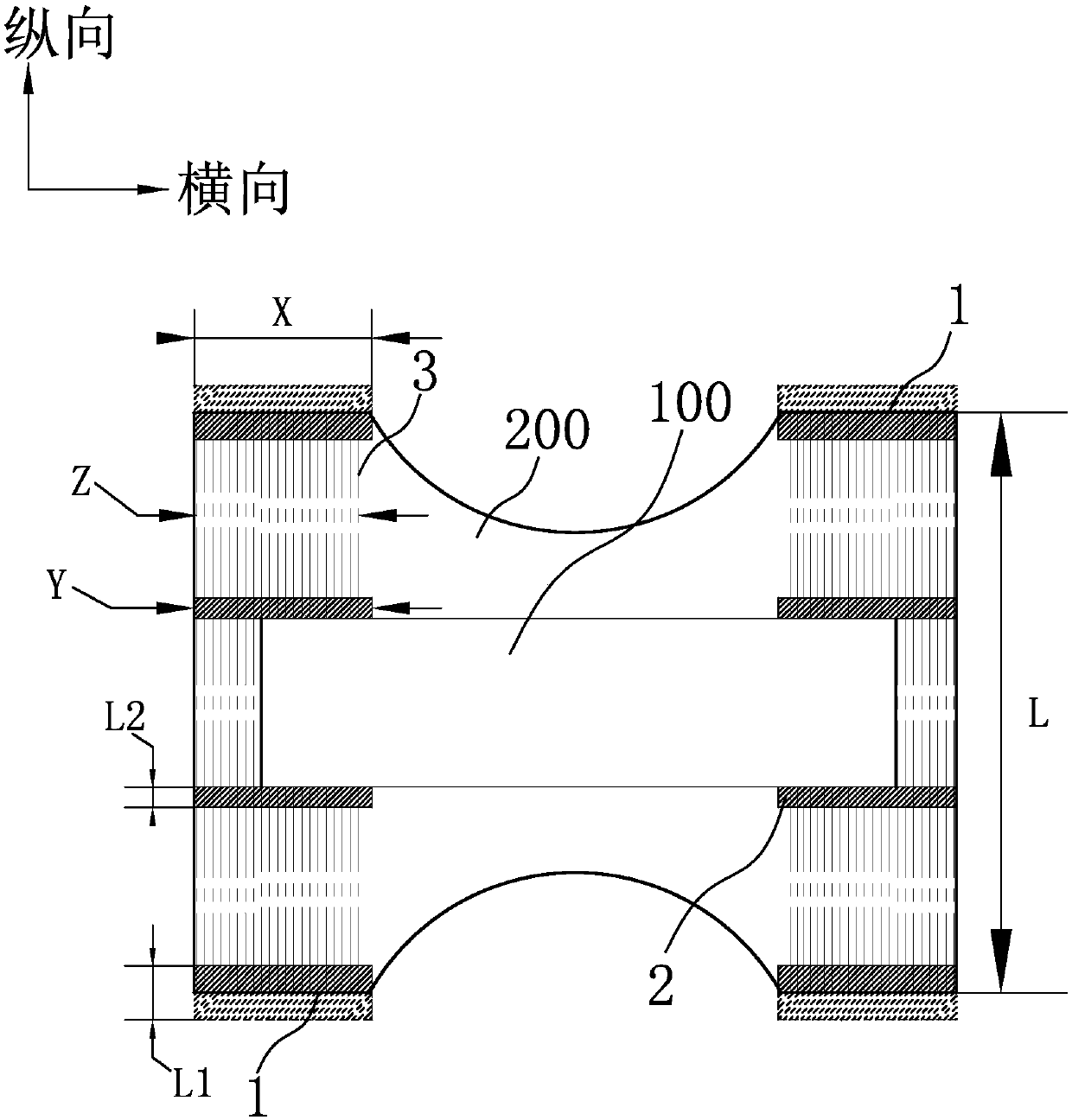

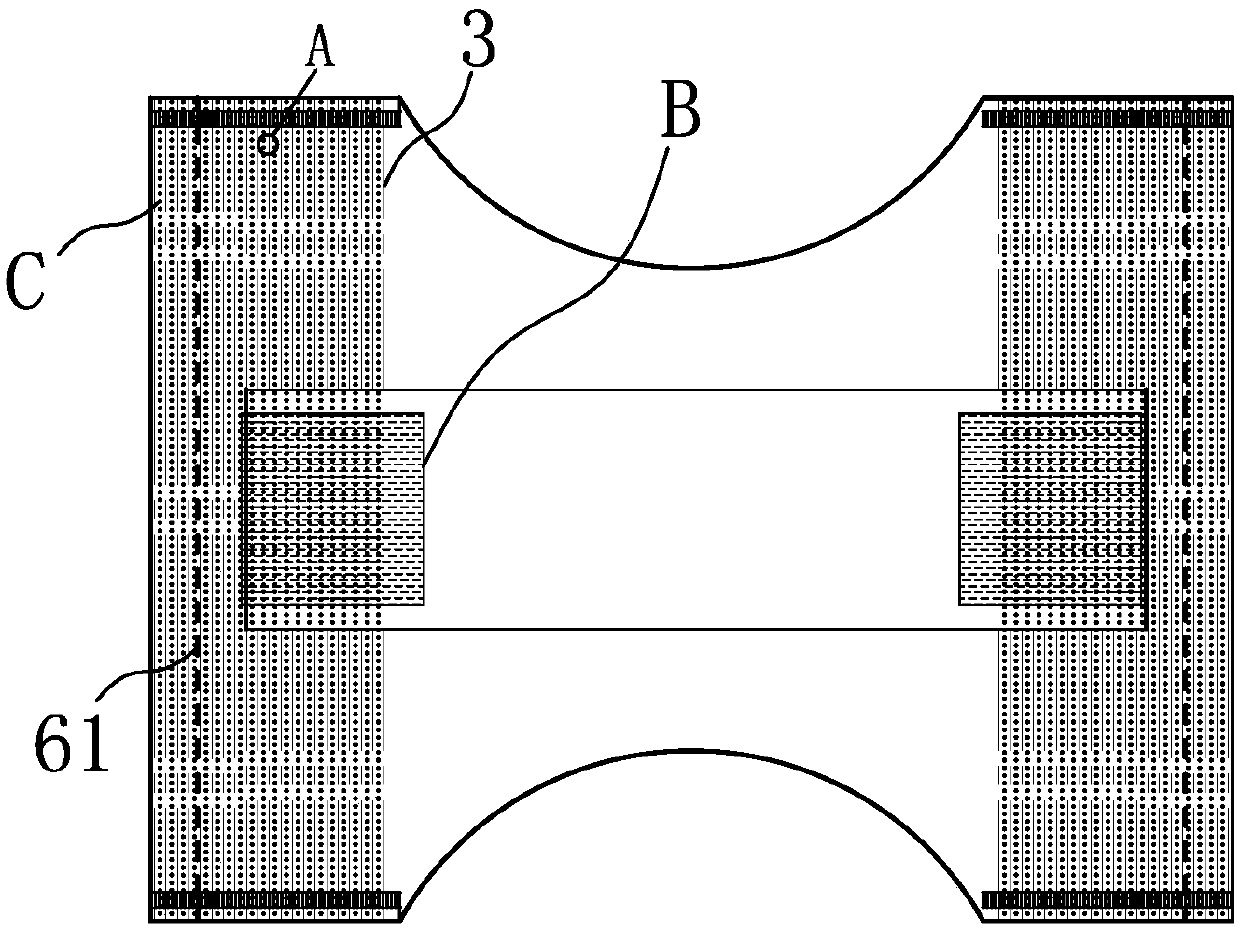

[0037] A kind of preparation method of the breathable absorbent article of waist circumference, such as figure 1 , figure 2 , image 3 and Figure 4 shown, including the following steps:

[0038] 1), preparing the absorbent body and cutting it into individual absorbent bodies 100 separated from each other;

[0039] 2), preparing the clothing layer 200;

[0040] 3), rotating the absorber 100 by 90 degrees relative to its own conveying direction;

[0041] 4), the two ends of the absorber 100 along the length direction are respectively fixedly connected to the clothing layer 200;

[0042] 5), defined in the horizontal plane, the direction along which the clothing layer 200 is transported is the longitudinal direction, and the direction perpendicular to the longitudinal direction is the horizontal direction, and the clothing layer 200 and the absorbent body 100 on it are folded together along the horizontal direction, and The longitudinal sides of the absorbent body 100 are...

Embodiment 2

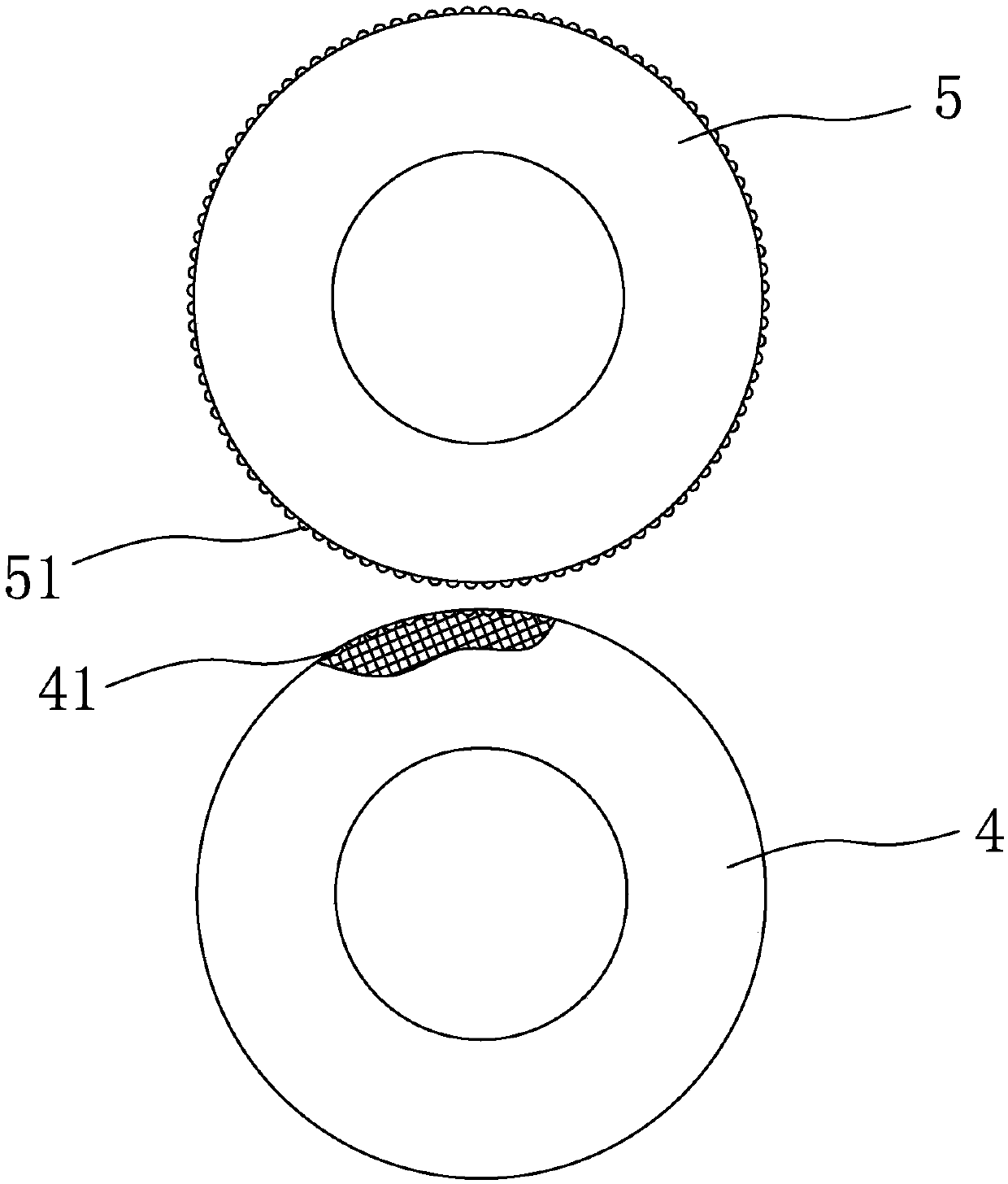

[0054] Such as Figure 5 As shown, compared with the first embodiment, the sealing glue 1 and the adhesive glue 2 in the step a) are realized by spraying spiral glue.

[0055] In the present invention, the adhesive glue 2 can be set in 2 to 4 lanes according to different sizes; at the same time, the cross-sectional area and radial height of each needle 51 can be adjusted and set according to actual needs, and the effect of punching and welding can be achieved. Can.

[0056] The invention sets the waistline structure as a double-layer non-woven fabric structure by improving the production process, adding elastics at the waistline between the two layers of non-woven fabrics, and opening air holes between the elastics, structurally ensuring that the clothing layer at the waistline is Excellent air permeability also makes the elastic evenly distributed, ensuring the uniformity of stretching at the waist and improving the wearing comfort;

[0057] Adopt the form of discontinuousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com