Ready-to-eat fish gelatin and preparation process thereof

A production process and isinglass technology, applied in food science and other directions, can solve the problems of complicated production process, high production cost, and fishy fish maw, and achieve the effects of good maintenance effect, increased energy, and increased taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of ready-to-eat fish maw, the formula comprises: fish maw, red kidney bean, millet, shredded chicken, pumpkin, abalone, pork bone meal, oyster sauce, peanut oil, clear water and edible salt, and the parts by weight of each component are counted as: fish maw 5 1.8 parts of red kidney beans, 8 parts of millet, 0.7 parts of shredded chicken, 2.0 parts of pumpkin, 0.4 parts of abalone, 0.12 parts of pork bone meal, 1 part of oyster sauce, 1.5 parts of peanut oil, 8 parts of water and 0.9 parts of edible salt.

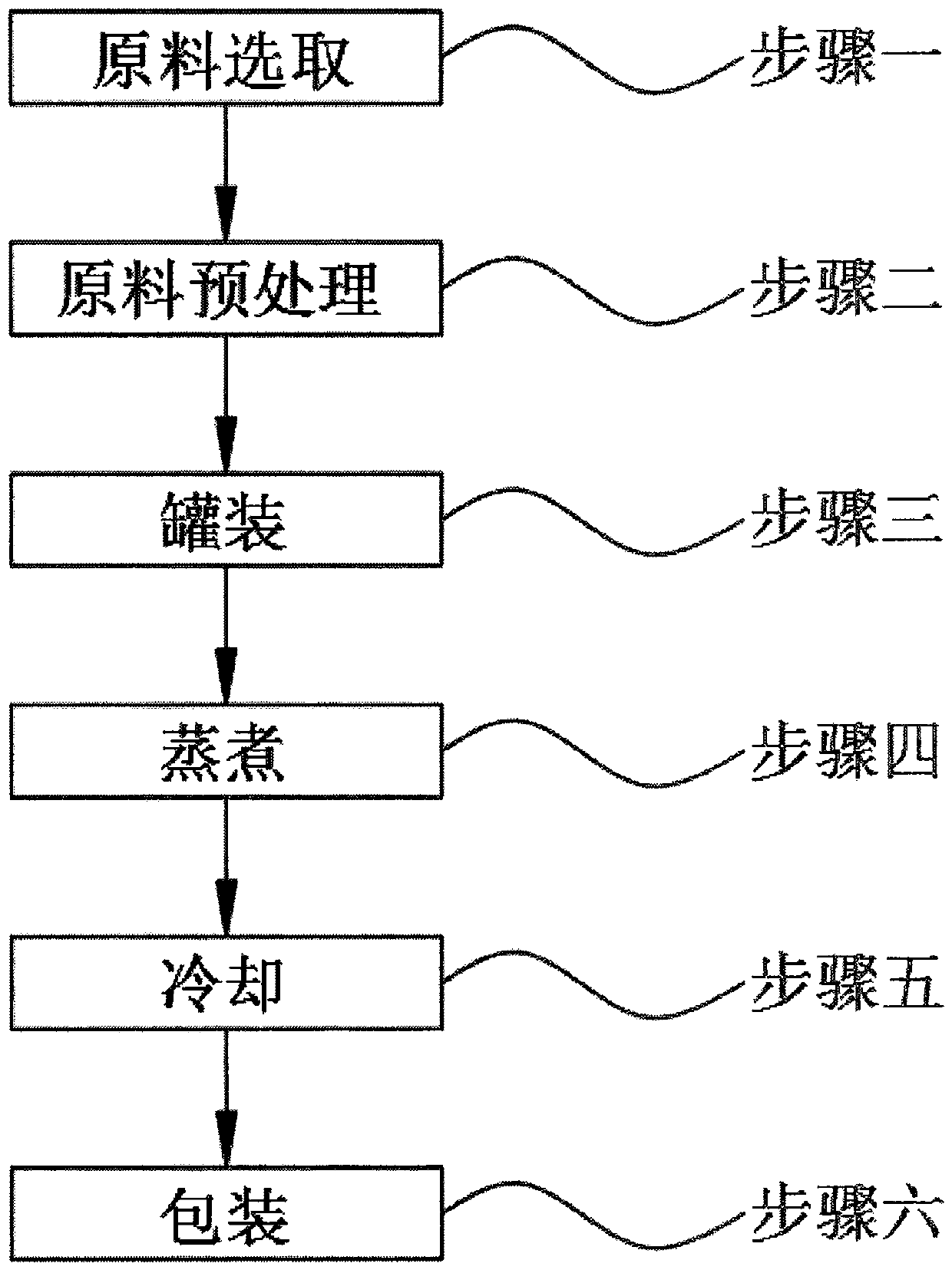

[0034] A manufacturing process of instant isinglass, comprising step 1, raw material selection; step 2, raw material pretreatment; step 3, canning; step 4, cooking; step 5, cooling; step 6, packaging;

[0035] Wherein in the above-mentioned step 1, counting according to the parts by weight of each component is: 5 parts of fish maw, 1.8 parts of red kidney beans, 8 parts of millet, 0.7 parts of shredded chicken, 2.0 parts of pumpkin, 0.4 parts of abalone, 0.12 p...

Embodiment 2

[0051] A kind of ready-to-eat fish maw, the formula comprises: fish maw, red kidney bean, millet, shredded chicken, pumpkin, abalone, pork bone powder, oyster sauce, peanut oil, clear water and edible salt, and the parts by weight of each component are counted as: fish maw 4 2 parts of red kidney beans, 10 parts of millet, 0.7 parts of shredded chicken, 2.2 parts of pumpkin, 0.2 parts of abalone, 0.15 parts of pork bone meal, 1.2 parts of oyster sauce, 2 parts of peanut oil, 7 parts of water and 1 part of edible salt.

[0052] A manufacturing process of instant isinglass, comprising step 1, raw material selection; step 2, raw material pretreatment; step 3, canning; step 4, cooking; step 5, cooling; step 6, packaging;

[0053] Wherein the above-mentioned step 1, counting according to the parts by weight of each component is: 4 parts of fish maw, 2 parts of red kidney beans, 10 parts of millet, 0.7 part of shredded chicken, 2.2 parts of pumpkin, 0.2 part of abalone, 0.15 part of ...

Embodiment 3

[0069] A kind of ready-to-eat fish maw, the formula comprises: fish maw, red kidney bean, millet, shredded chicken, pumpkin, abalone, pork bone powder, oyster sauce, peanut oil, clear water and edible salt, the weight parts count of each component is: fish maw 6 1.8 parts of red kidney beans, 13 parts of millet, 0.8 parts of shredded chicken, 1.5 parts of pumpkin, 0.4 parts of abalone, 0.12 parts of pork bone meal, 1 part of oyster sauce, 1.8 parts of peanut oil, 8 parts of water and 1.2 parts of edible salt.

[0070] A manufacturing process of instant isinglass, comprising step 1, raw material selection; step 2, raw material pretreatment; step 3, canning; step 4, cooking; step 5, cooling; step 6, packaging;

[0071] Wherein in the above-mentioned step 1, counting according to the parts by weight of each component is: 6 parts of fish maw, 1.8 parts of red kidney beans, 13 parts of millet, 0.8 parts of shredded chicken, 1.5 parts of pumpkin, 0.4 parts of abalone, 0.12 parts of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com