Pneumatic tire

A technology for pneumatic tires and treads, which is applied to special tires, tire parts, tire treads/tread patterns, etc., which can solve the problems of reduced tire electrification suppression performance and reduced discharge performance, so as to suppress separation and improve separation resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

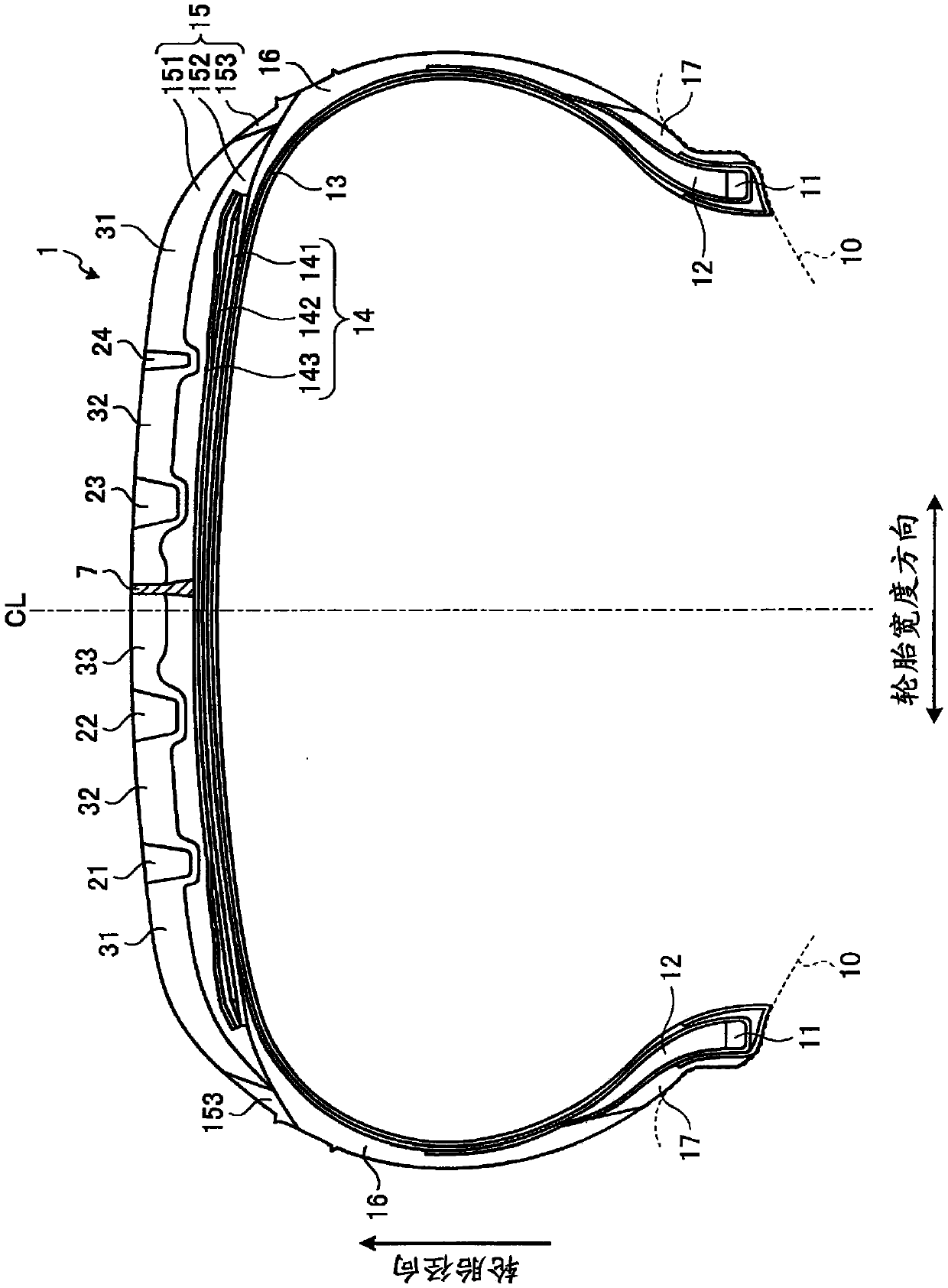

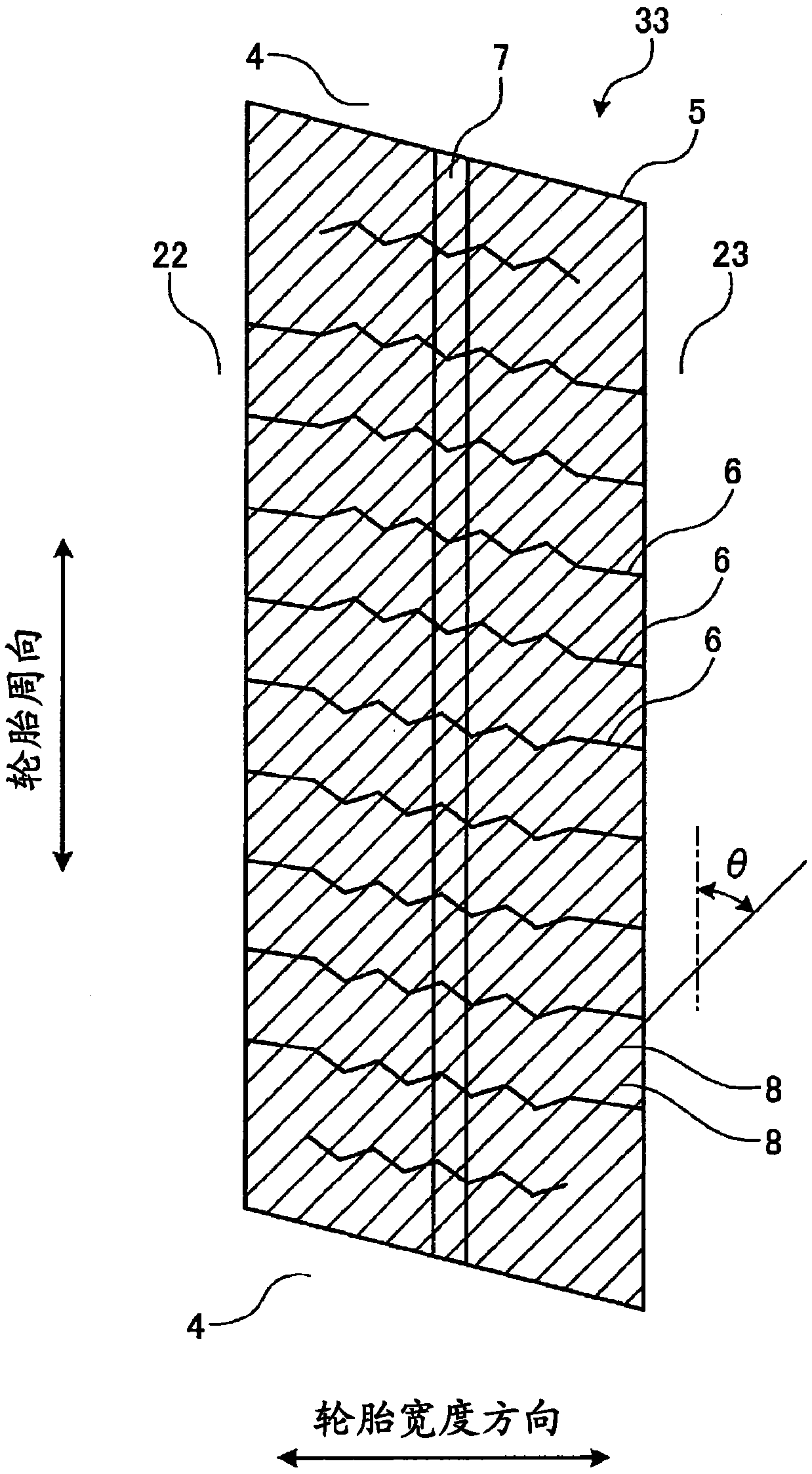

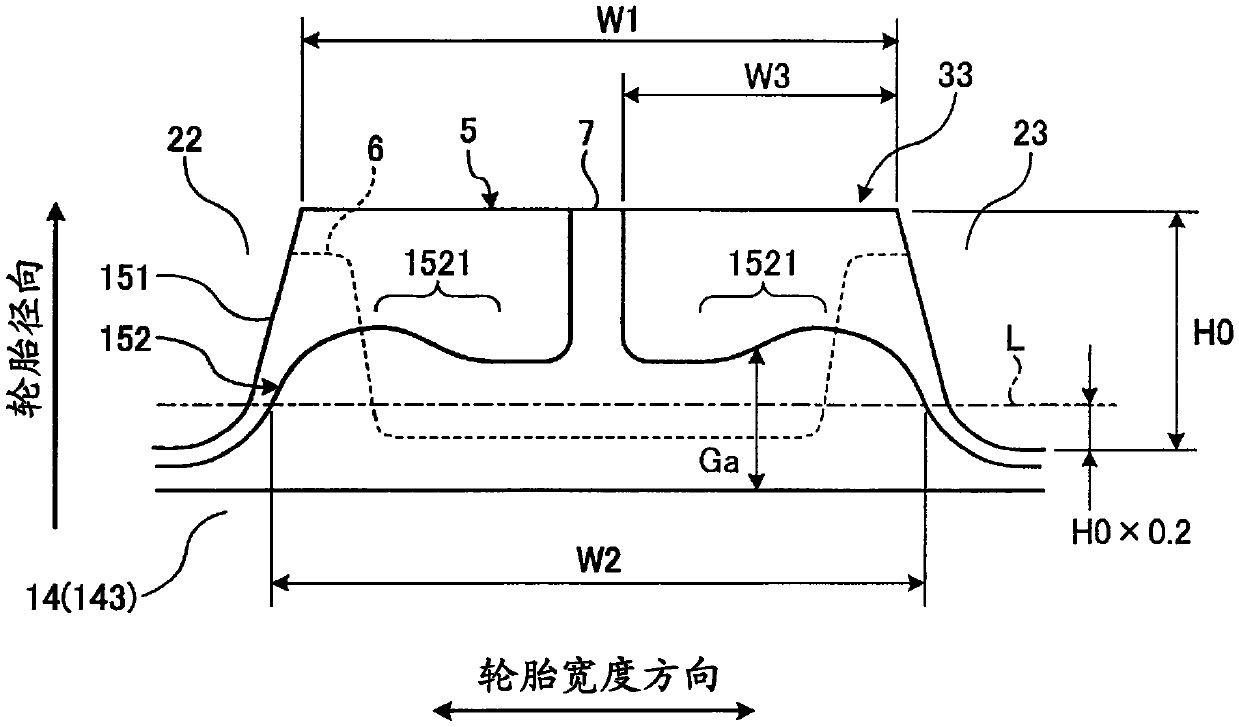

[0153] Figure 9 It is a graph showing the results of the performance test of the pneumatic tire according to the embodiment of the present invention. Figure 10 It is an explanatory diagram showing a test tire of a conventional example.

[0154] In this performance test, evaluations related to (1) braking performance on ice, (2) electrification suppression performance (resistance value), and (3) separation resistance performance were performed on a plurality of different pneumatic tires (see Figure 9 ). In this performance test, a pneumatic tire having a tire size of 195 / 65R15 91Q was assembled to a rim having a rim size of 15×6J, and an air pressure of 210 [kPa] and a load specified by JATMA were applied to the pneumatic tire. In addition, the pneumatic tire was attached to a four-wheel-drive passenger car with a displacement of 3.0 [L] as a test vehicle.

[0155] (1) In the evaluation related to braking performance on ice, a test vehicle was run on a predetermined icy r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com