Reverse-flow type double-air-channel cooling system for energy storage module

A cooling system and energy storage module technology, applied to electrochemical generators, electrical components, circuits, etc., can solve the uneven distribution of air volume in the air cooling system, high temperature of the battery energy storage module, and large temperature difference of the battery energy storage module and other problems, to achieve the effect of eliminating uneven distribution of air volume, enhancing heat transfer, and cooling medium safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

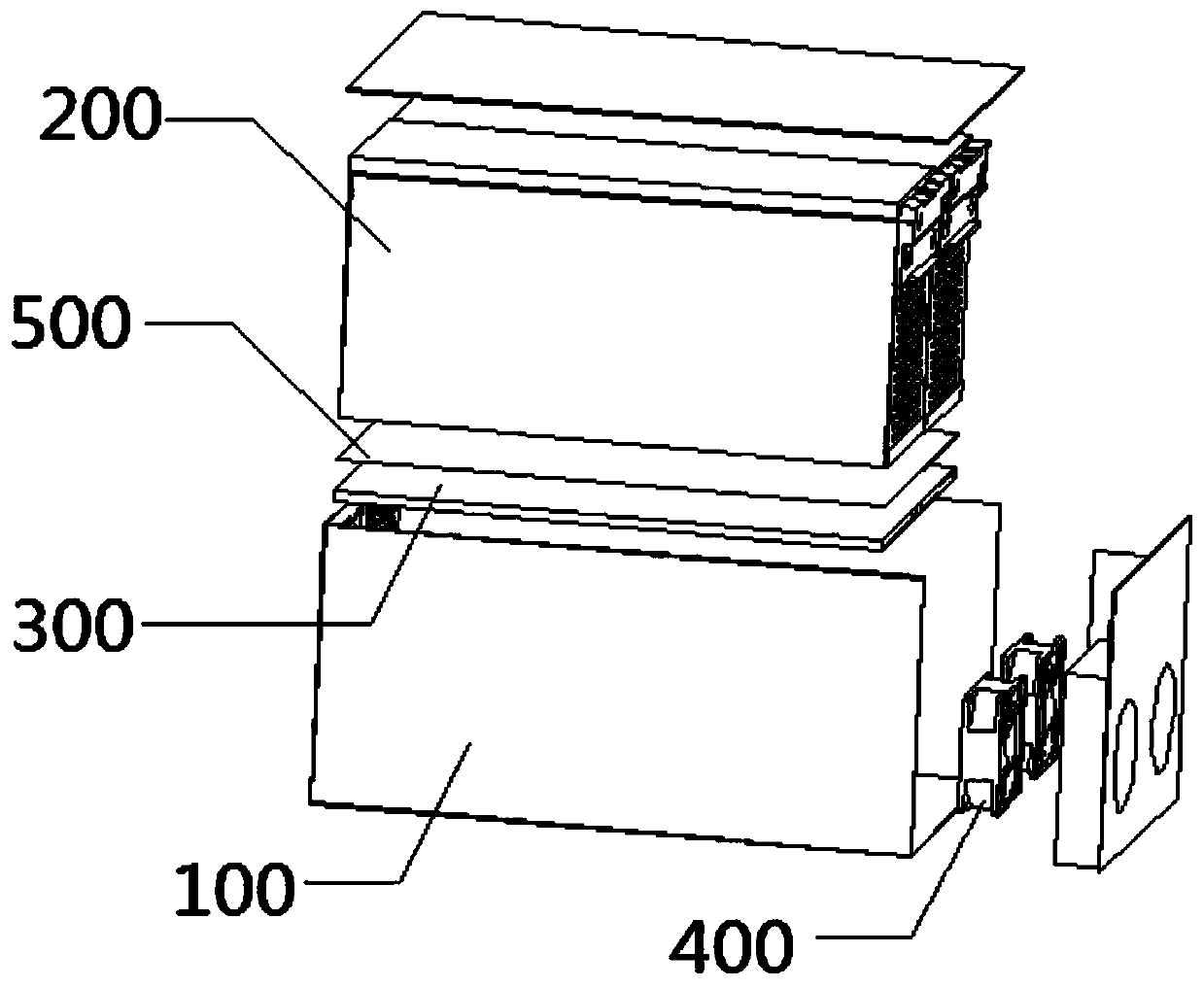

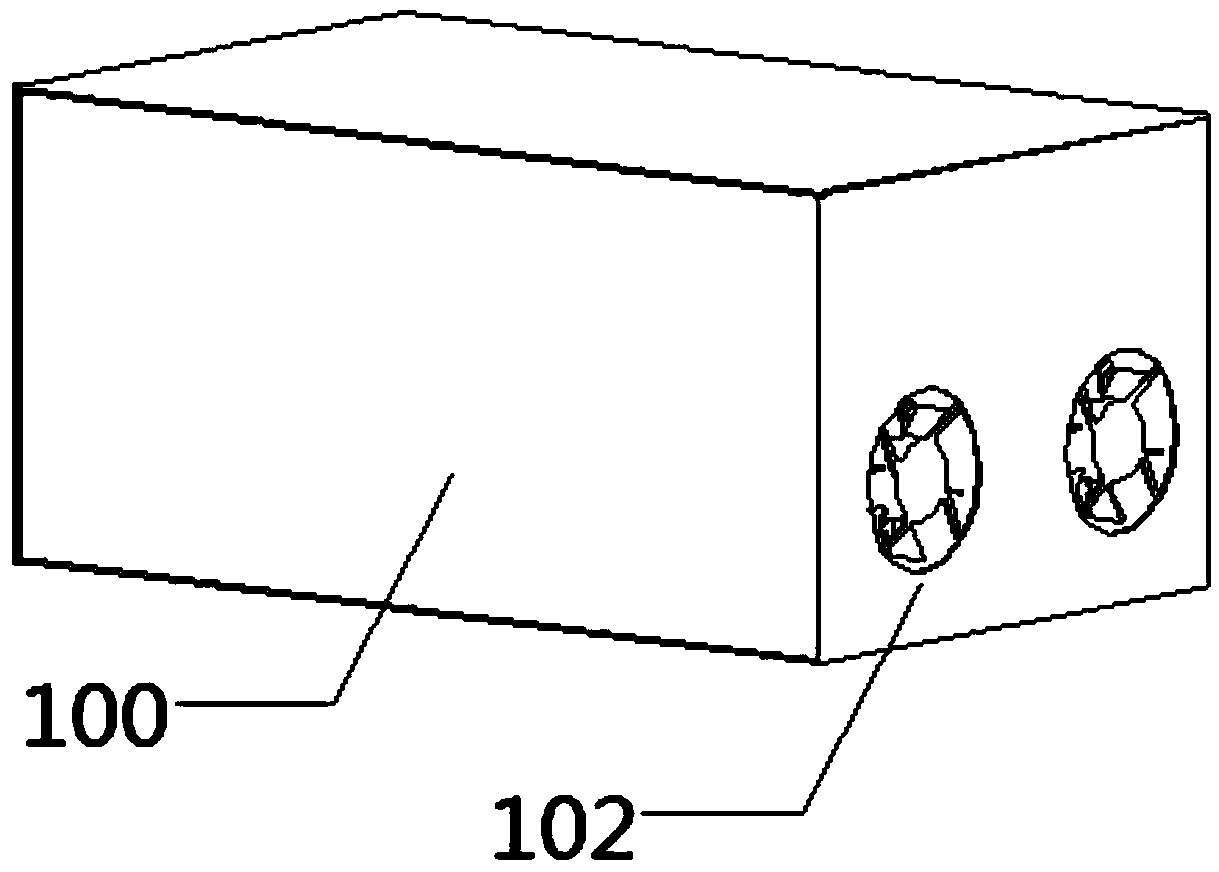

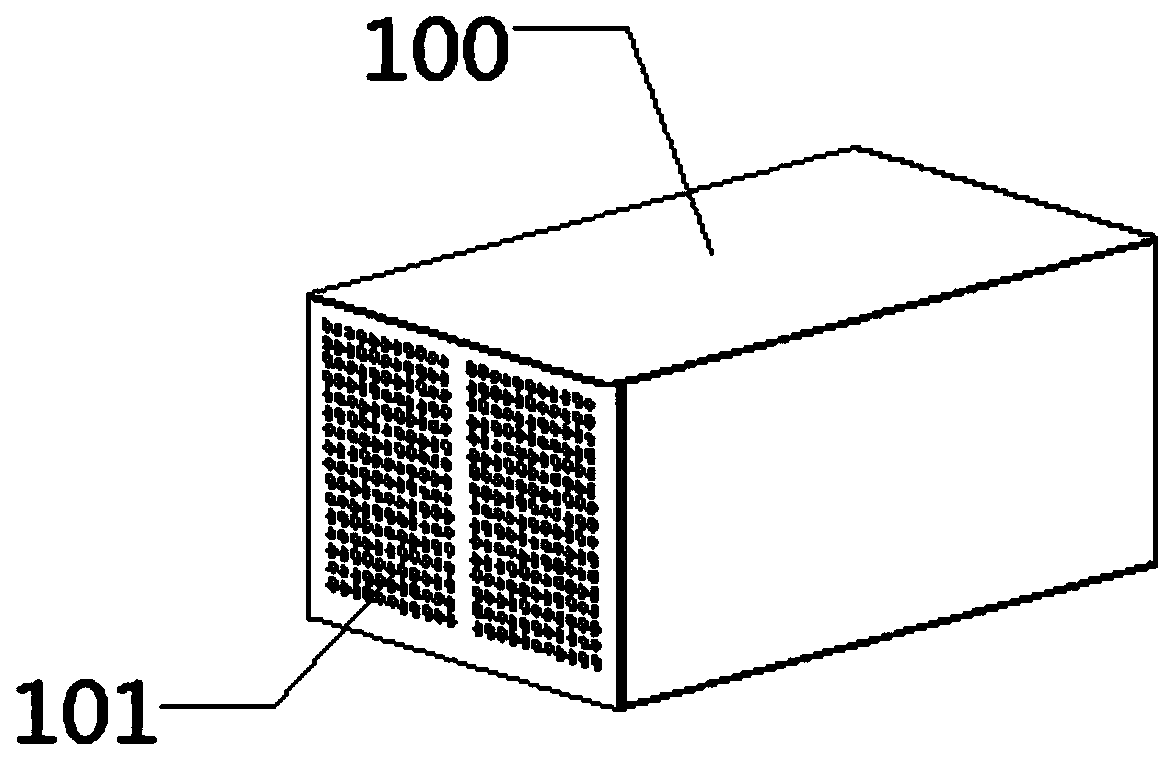

[0031] A counter-flow dual-air duct cooling system for an energy storage module, such as Figure 1-6 As shown, it includes a box body 100, an air exhaust device 400, an energy storage module and a heat dissipation device 300. 400 is connected to the energy storage module 200, the energy storage module 200 is set on the heat dissipation device 300; At the air outlet 102, the energy storage module 200 includes a plurality of single battery cells 201, and there is a gap between two single battery cells 201, and the gap forms a first air duct 202 for air flow. The first air duct 202 communicates with the air inlet 101 and the air outlet 102 of the box body 100; the inside of the heat dissipation device 300 is provided with a second air duct 301 opposite to the air flow of the first air duct 202. The air duct 301 communicates with the air inlet 101 and the air outlet 102 of the box body 100 , and forms a counter-flow double air duct cooling system through the first air duct 202 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com