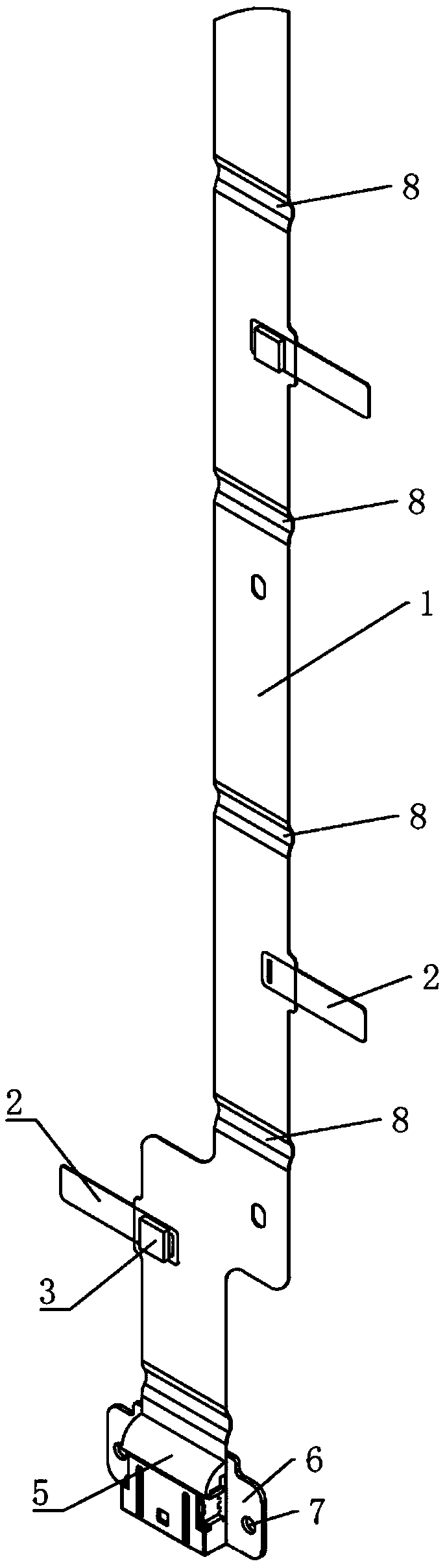

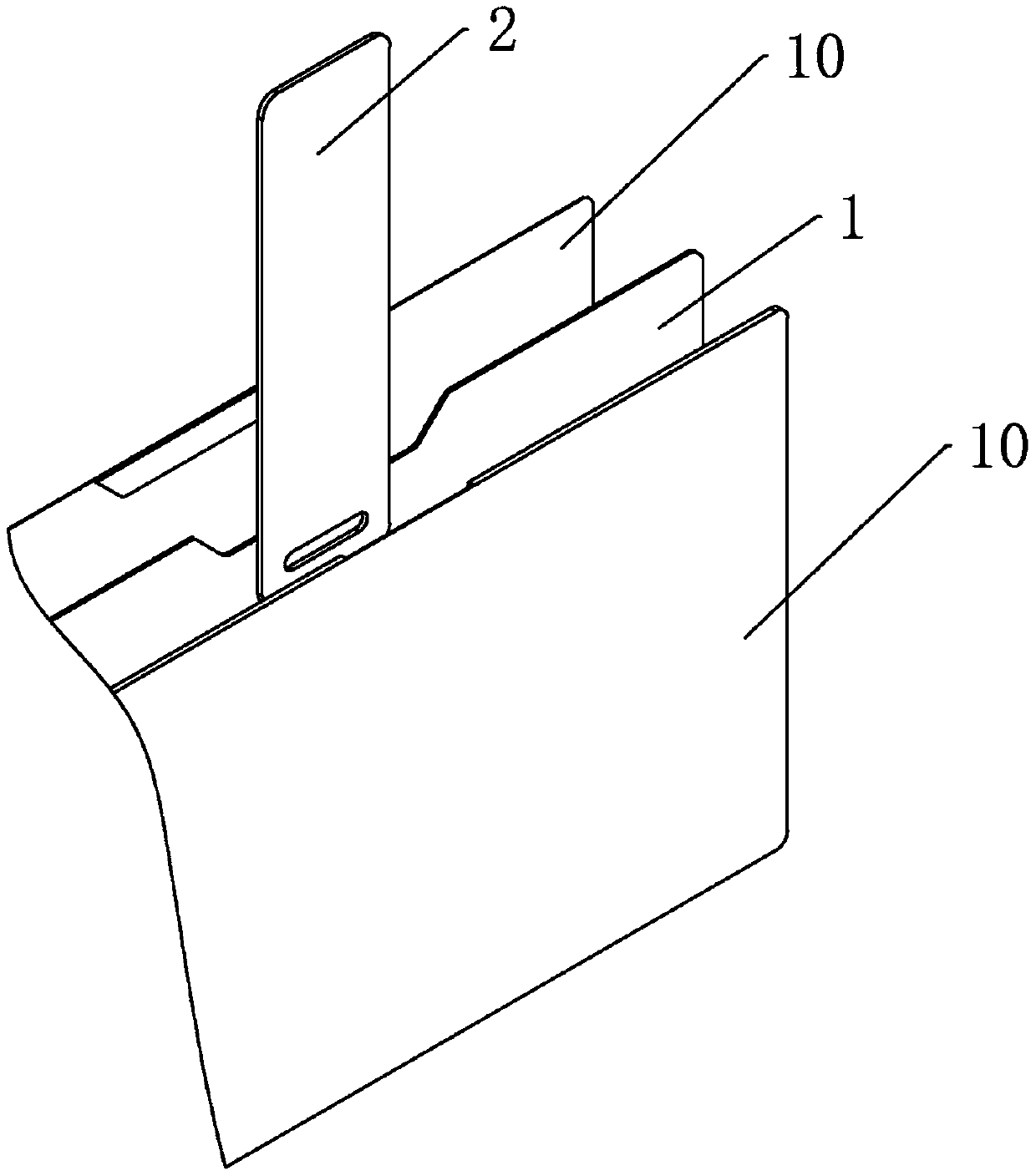

Battery signal acquisition wire harness with bending structure and bending process thereof

A battery signal and acquisition line technology, applied to structural parts, battery pack components, circuits, etc., can solve the problems of battery management system signal acquisition failure, battery signal acquisition harness damage, battery signal acquisition harness pulling, etc., to ensure the use of Longevity, ease of implementation, and stable bending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

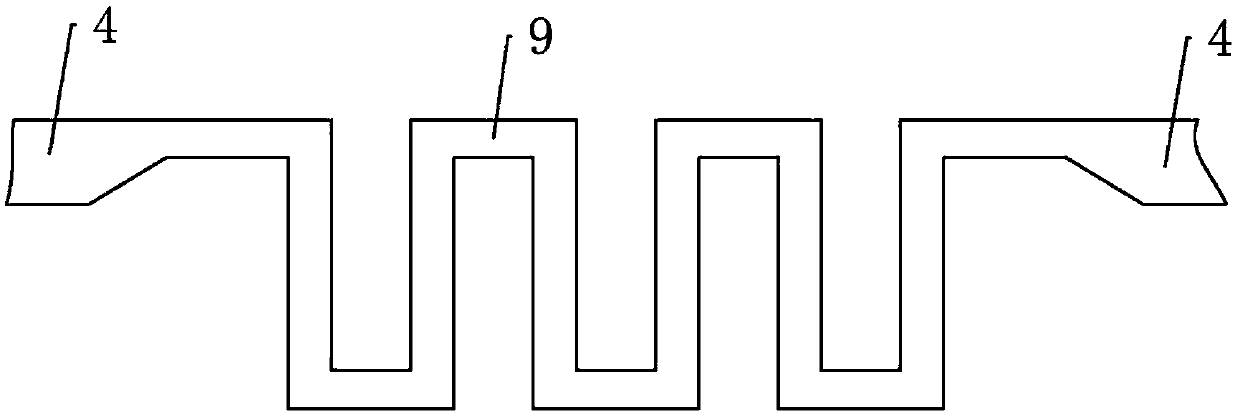

[0031] Specific embodiment 1: A bending process of a battery signal acquisition wiring harness with a bending structure of the present invention includes the following steps:

[0032] Step S1: Preheating: heating the circuit board to 75°C for 5 minutes;

[0033] Step S2: Hot pressing: Select the corresponding hot pressing mold according to the shape of the bending part to hot press the circuit board preheated in step S1, the hot pressing temperature is 120°C, and the hot pressing duration is 10 minutes;

[0034] Step S3: cooling: cooling the circuit board hot-pressed in step S2 to 20°C-30°C for 5 minutes, and the cooling method is air cooling;

[0035] Step S4: heat preservation: heat the circuit board cooled in step S3 to 70°C and keep it in the range of 60°C-80°C, and the heat preservation time is 10 minutes;

[0036] Step S5: Sizing: Select the corresponding sizing device according to the shape of the bending part, and sizing the circuit board after heat preservation in st...

specific Embodiment 2

[0037] Specific embodiment 2: A bending process of a battery signal acquisition wiring harness with a bending structure of the present invention includes the following steps:

[0038] Step S1: Preheating: heating the circuit board to 80°C for 7 minutes;

[0039] Step S2: Hot pressing: Select the corresponding hot pressing mold according to the shape of the bending part to hot press the circuit board preheated in step S1, the hot pressing temperature is 110°C, and the hot pressing duration is 15 minutes;

[0040] Step S3: cooling: cooling the circuit board hot-pressed in step S2 to 30°C for 3 minutes, and the cooling method is air cooling;

[0041] Step S4: heat preservation: heat the circuit board cooled in step S3 to 80°C and keep it within the range of 60°C-80°C, and the heat preservation time is 15 minutes;

[0042]Step S5: Sizing: Select the corresponding sizing device according to the shape of the bending part, and set the circuit board after heat preservation in step S4...

specific Embodiment 3

[0043] Specific embodiment 3: A bending process of a battery signal acquisition wiring harness with a bending structure of the present invention includes the following steps:

[0044] Step S1: Preheating: heating the circuit board to 70°C for 6 minutes;

[0045] Step S2: Hot pressing: Select the corresponding hot pressing mold according to the shape of the bending part to hot press the circuit board preheated in step S1, the hot pressing temperature is 115°C, and the hot pressing duration is 18 minutes;

[0046] Step S3: cooling: cooling the circuit board hot-pressed in step S2 to 25°C for 3 minutes, and the cooling method is air cooling;

[0047] Step S4: heat preservation: heat the circuit board cooled in step S3 to 70°C and keep it in the range of 60°C-80°C, and the heat preservation time is 12 minutes;

[0048] Step S5: Sizing: Select the corresponding sizing device according to the shape of the bending part, and sizing the circuit board after heat preservation in step S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com