Simulation device and method for dynamic corrosion of gas reservoir sand-proof screen pipe and evaluation method for dynamic corrosion performance of sand-proof screen pipe

A sand control screen and dynamic corrosion technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of quantitative testing of corrosion laws, failure of mechanical sand control screen corrosion testing, and inability to realize dynamic corrosion simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

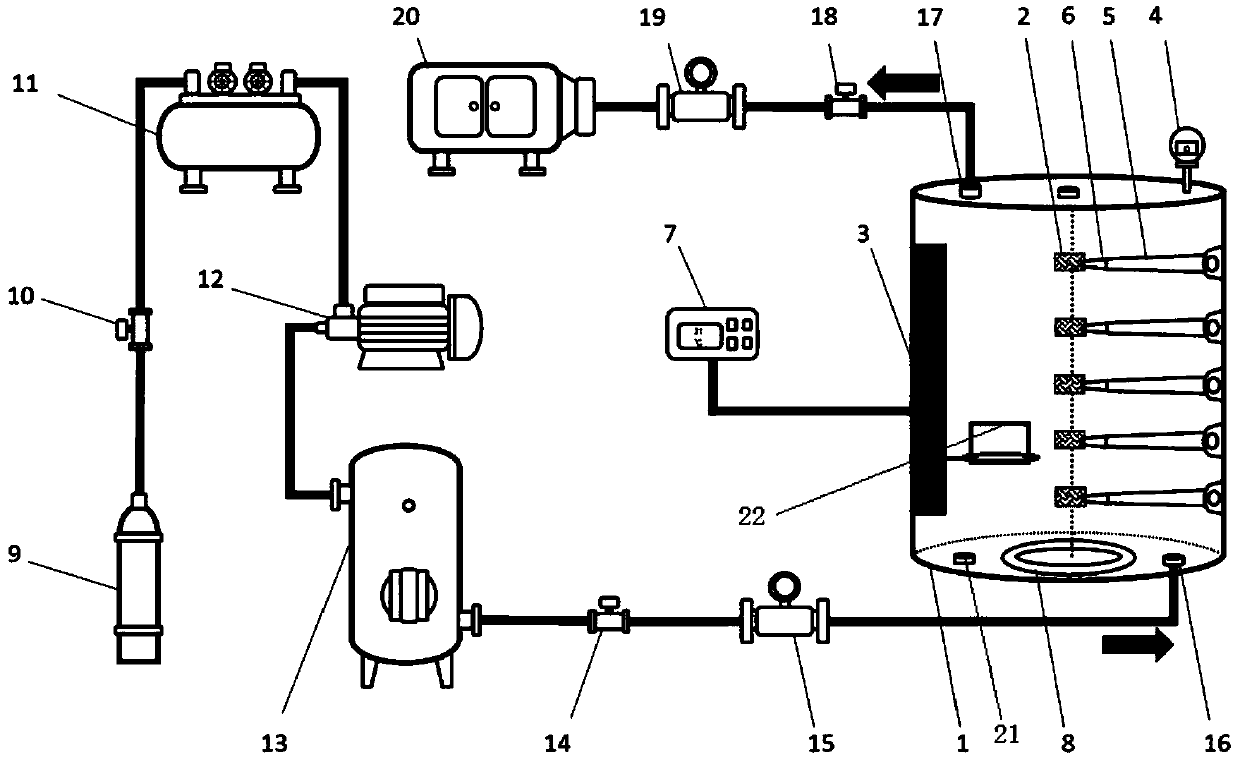

[0065] A dynamic corrosion simulation device for sand control screens in gas reservoirs, the structure of which is as follows: figure 1 figure 2 As shown, the simulation device includes a screen pipe corrosion simulation module, a high-pressure gas pumping module, and an exhaust module;

[0066] The high-pressure gas pumping module includes a connected gas source module and a booster module, the booster module is connected to the gas inlet of the screen corrosion simulation module, and the gas source module includes gas cylinders 9 and The air compressor 11, the booster module includes a booster pump 12 and a pressure-stabilizing air storage tank 13, the gas cylinder 9 is connected with the air intake pipe of the air compressor 11, and the air outlet pipe of the air compressor is connected with the inlet of the booster pump 12. The outlet of the pressure pump 12 is connected to the inlet of the pressure-stabilizing gas storage tank 13 through a connecting pipe, and the outle...

Embodiment 2

[0072] A dynamic corrosion simulation device for sand control screens in gas reservoirs, which is the same as that in Embodiment 1, except that:

[0073]The lower part of the simulated shaft is equipped with a sand holding device, which is installed on the snap ring, and the snap ring is fixedly connected to the side wall of the simulated shaft through a support rod. The sand holding device includes a sand holding container, the bottom, top and side of the sand holding container There are sand leakage holes evenly distributed on the wall, and sand particles of different particle sizes are arranged in the sand holding container, and the sand holding device deviates from the liquid inlet hole and the gas inlet. Under the force of the fluid, the sand particles with small particle size flow out from the sand container through the sand leakage hole, and are mixed in the fluid to form a sand-containing fluid. The sand particles hit and collide with the side wall of the screen pipe, a...

Embodiment 3

[0075] A dynamic corrosion simulation device for sand control screens in gas reservoirs, which is the same as that in Embodiment 1, except that:

[0076] The sand control screen is a multi-short screen, and the structure of the short screen includes the following three situations: a, the base pipe and the outer protective pipe sleeved outside the base pipe, b, the base pipe and the outer protective pipe sleeved outside the base pipe c, the base pipe and the outer protection pipe sleeved outside the base pipe, the filter member is sleeved between the base pipe and the outer protection pipe, and the structure of the adjacent sub-section screen pipes is different.

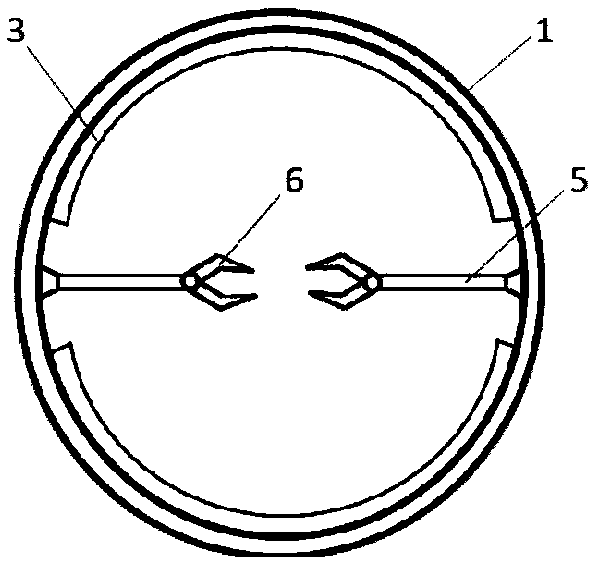

[0077] The length of each nipple screen pipe is 5-15cm, and fixed seats are arranged at intervals up and down on the side wall of the simulated wellbore, and the movable arm 5 pointing to the center of the circle is connected to the fixed seat, and the end of each movable arm is connected with a gripper 6. Each sub-se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com