Linear laser measuring system used for high temperature continuous casting billet and method thereof

A linear laser and measurement system technology, applied in the field of laser measurement, can solve problems such as difficulty in detection of round billets, wear, and decrease in measurement accuracy, and achieve high-precision and high-efficiency identification and measurement, improved identification accuracy, and efficient and feasible measurement effect of means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

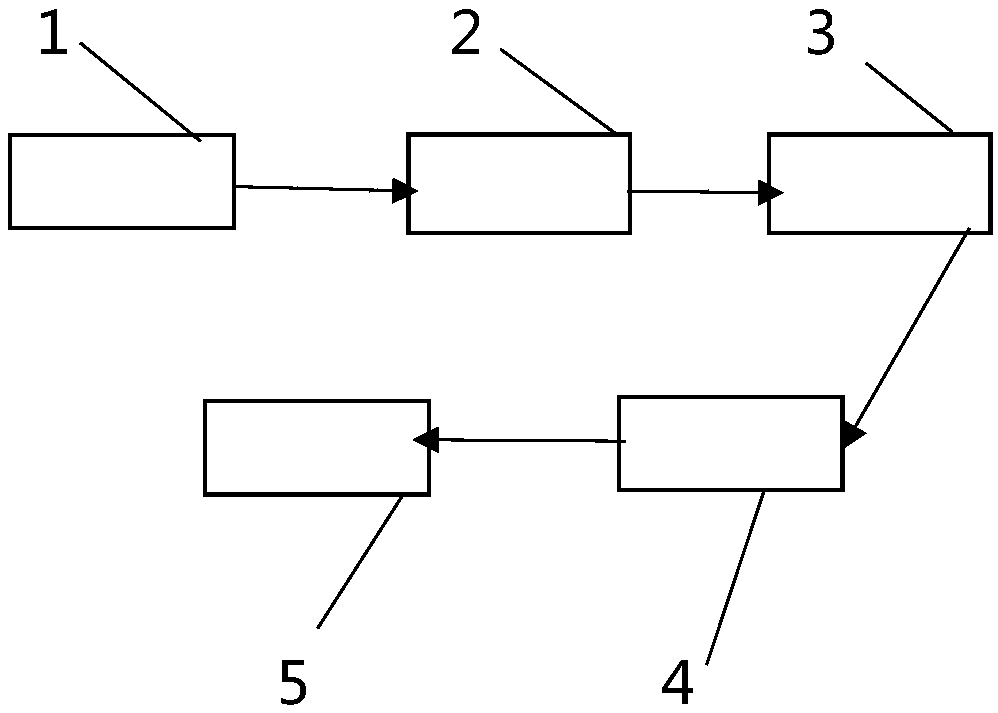

[0018] An embodiment, a linear laser measurement system for high temperature continuous casting slabs, is composed of a linear laser 1, an imaging lens 2, an area array CDD3, a supporting communication module 4, and a computer 5 connected by means of photoelectric signals (see attached figure 1 shown).

[0019] The working process of the present invention is as follows:

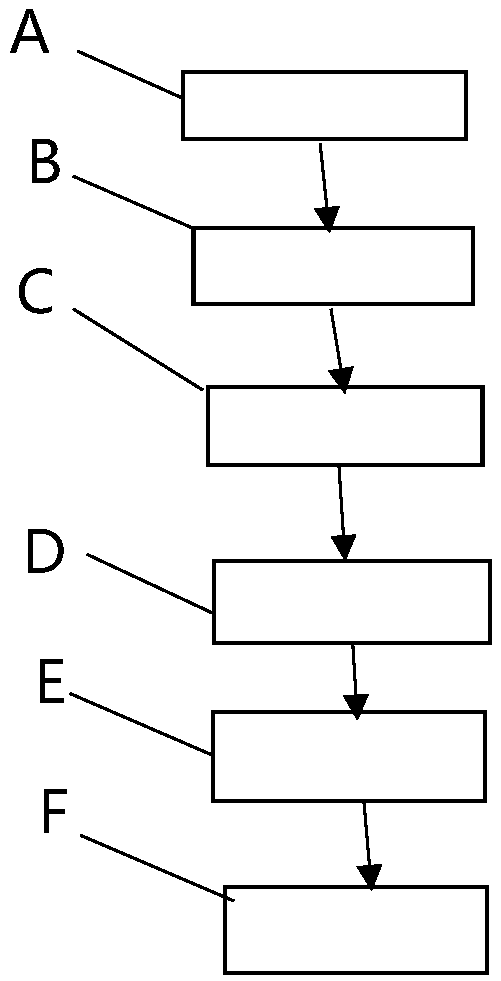

[0020] A method for a linear laser measurement system for high-temperature continuous casting slabs is characterized in that it includes the following steps (as attached figure 2 shown):

[0021] A. The signal point informs the high temperature continuous casting slab to arrive at the measurement area;

[0022] B. Start the linear laser 1 to project continuous laser lines on the surface of the high-temperature continuous casting slab;

[0023] C. Two imaging lenses for high-frequency scanning capture;

[0024] D. Form a two-dimensional image with high-precision pixels through the area array CDD3;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com