Textile rapid cotton cloth drying device with sterilizing function

A fast drying and functional technology, applied in the textile field, can solve the problems of slow drying speed, labor trouble, time delay, etc., and achieve the effect of high efficiency and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

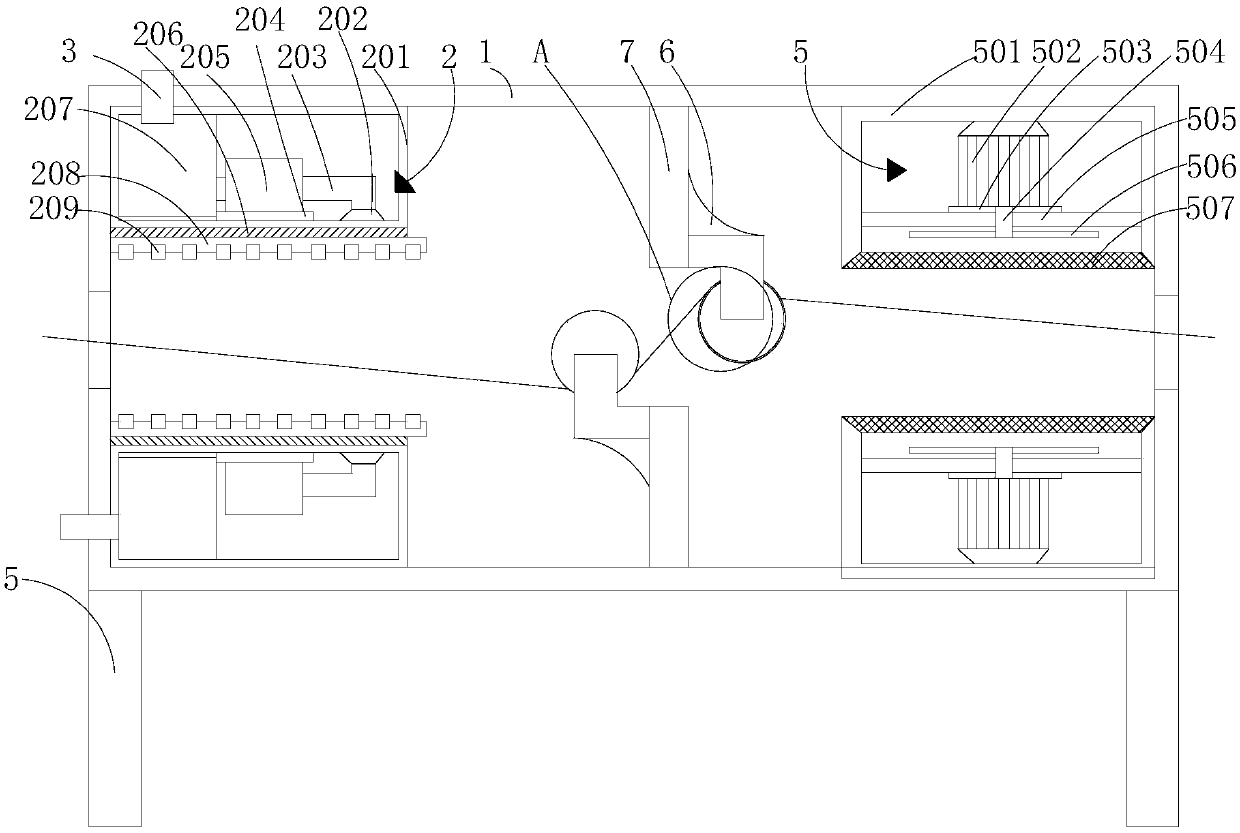

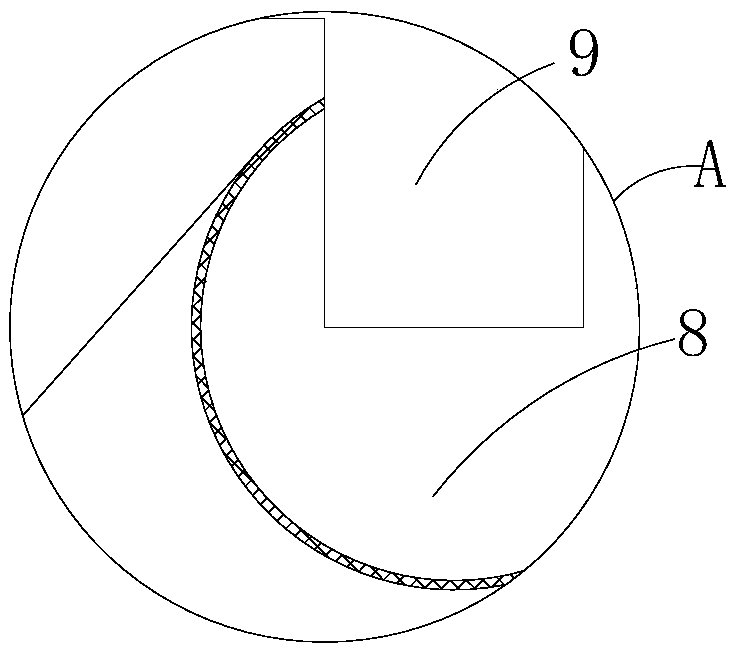

[0020] Such as Figure 1-2 As shown, the present invention provides a technical solution: a cotton rapid drying equipment with disinfection function for textiles, including an outer casing 1, a disinfection mechanism 2 and a drying mechanism 5, and the disinfection mechanism 2 includes an installation box 201 and a sealing gasket 202 , connecting elbow 203, driving device 205, backing plate 204, transition plate 206, disinfection water tank 207, mounting plate 208 and shower nozzle 209, the inner surface side of shell 1 is welded with the outer surface side of installation box 201, and installation box 201 One side of the inner surface of the installation box 207 is bonded to the outer surface of the disinfectant water tank 207, the bottom of the inner surface of the mounting box 201 is bonded to the bottom of the outer surface of the driving device 205, and the middle part of the outer surface of the driving device 205 is connected to the connecting elbow 203. One side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com