Wide-range swirling pulverized coal burner adopting flue gas recirculation for industrial pulverized coal boiler

A technology of flue gas recirculation and pulverized coal burner, which is applied in the direction of burning powder fuel, burning block fuel and gaseous fuel, burning liquid fuel and gaseous fuel, etc., and can solve fly ash combustibles High content, easy slagging in the furnace, high NOx emissions, etc., to avoid slagging and high-temperature corrosion in the furnace, avoid a large amount of generation, and have a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

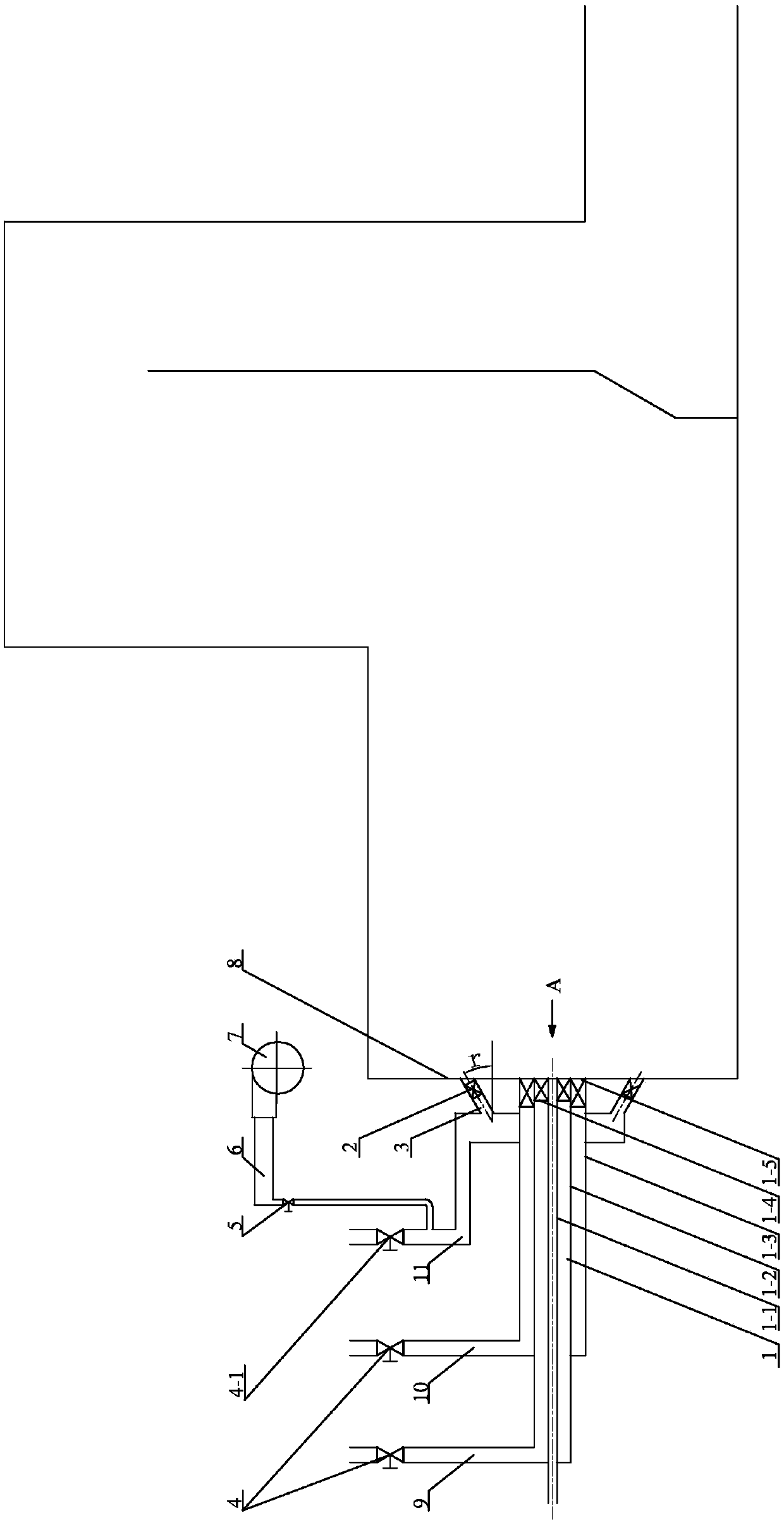

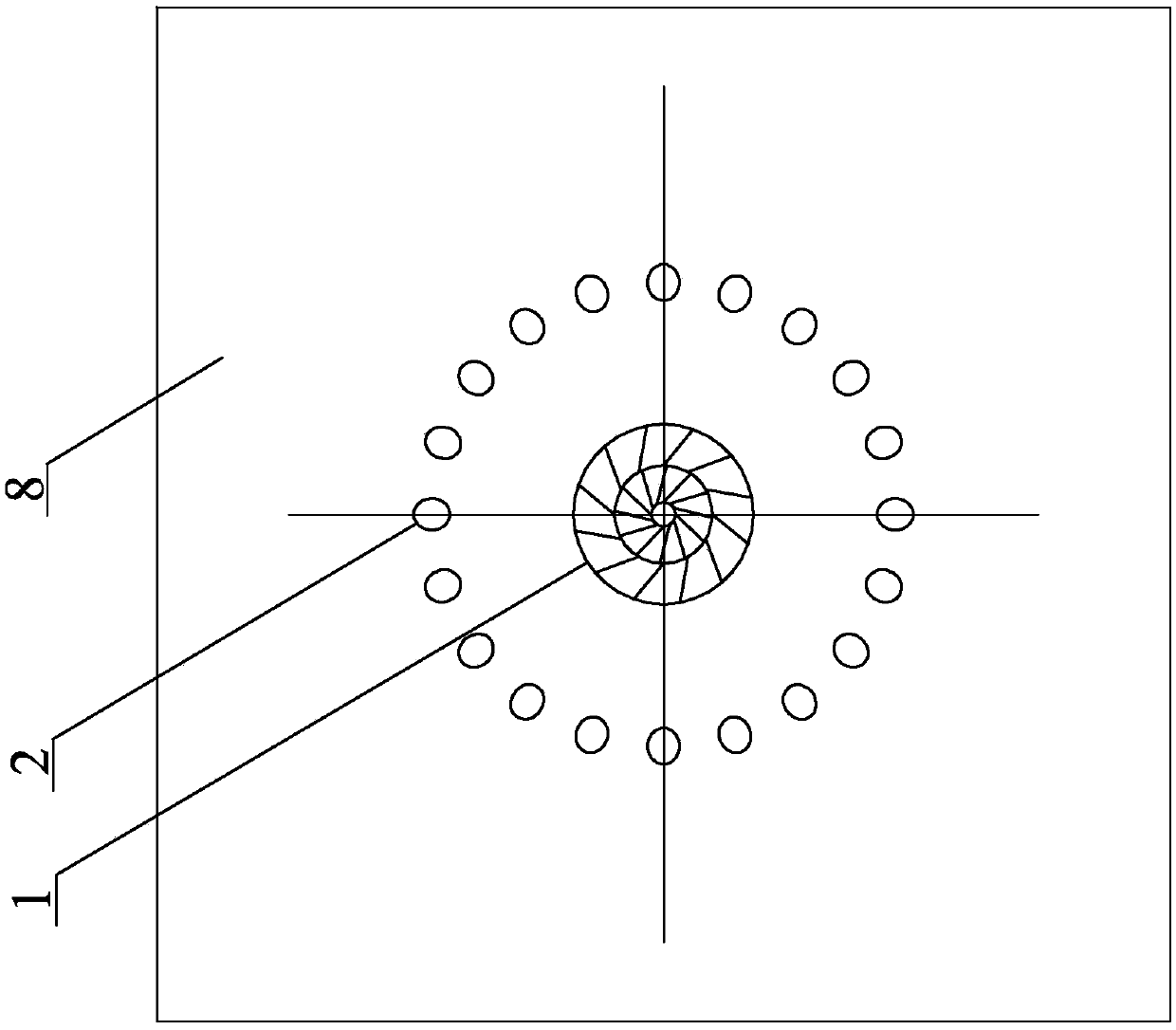

[0028] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, the industrial pulverized coal boiler described in this embodiment adopts a wide adjustment ratio swirl pulverized coal burner for flue gas recirculation, which includes a swirl pulverized coal burner 1, a recirculation flue gas pipeline 6, and a recirculation fan 7. Separated secondary air air pipe valve 4-1, first burner secondary air air pipe 9, second burner secondary air air pipe 10, separated secondary air air pipe 11, two burner secondary air Air pipe valve 4, a plurality of separated secondary air nozzle pipes 2 and a plurality of separated secondary air swirlers 3; the first burner secondary air air pipe 9 and the second burner secondary air air pipe 10 are respectively installed There is a burner secondary air air pipeline valve 4, a separated secondary air air pipeline 11 is installed with a separated secondary air air pipeline valve 4-1, and the swirl pulverized coal burne...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 This embodiment is described. The industrial pulverized coal boiler in this embodiment adopts a swirl pulverized coal burner with a wide adjustment ratio of flue gas recirculation. Air duct 1-2, secondary air duct 1-3 outside the swirl flow, secondary air swirl blades 1-4 inside and secondary swirl blades 1-5 outside, primary air duct 1-1, secondary air flow inside the swirl flow The pipe 1-2 and the secondary air pipe 1-3 outside the swirling flow are set coaxially in sequence from the inside to the outside, and an internal secondary swirling flow is installed between the primary air pipe 1-1 and the secondary air pipe 1-2 inside the swirling flow Blades 1-4, outer secondary swirl blades 1-5 are installed between the swirl inner secondary air duct 1-2 and the swirl outer secondary air duct 1-3, the length value of the primary air duct 1-1, The length value of the secondary air pipe 1-2 in the swirl flow and the le...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 Describe this embodiment, the industrial pulverized coal boiler described in this embodiment adopts a wide adjustment ratio swirl pulverized coal burner for flue gas recirculation, the primary air pipe 1-1, the secondary air pipe 1-2 in the swirl flow and the swirl flow A secondary air duct is respectively installed on the outer secondary air duct 1-3, and a plurality of separate secondary air ducts are evenly distributed and obliquely installed on the side wall of the secondary air duct located on the outer secondary air duct 1-3 of the swirling flow. The secondary air nozzle pipe 2, and a plurality of separated secondary air nozzle pipes 2 are arranged in a gradually expanding form from the secondary air air pipe to the boiler furnace front wall 8 of the horizontal boiler, and each separated secondary air nozzle pipe 2 The angle formed by the center line and the center line of the primary air duct 1-1 is r, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com