High-pressure gas holder

A gas tank and high-voltage technology, applied in the field of gas tank, can solve the problems of high labor intensity, random placement, unsafe, etc., and achieve the effects of ensuring safe operation, improving the ability of balanced and stable operation, and enhancing the ability to mediate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

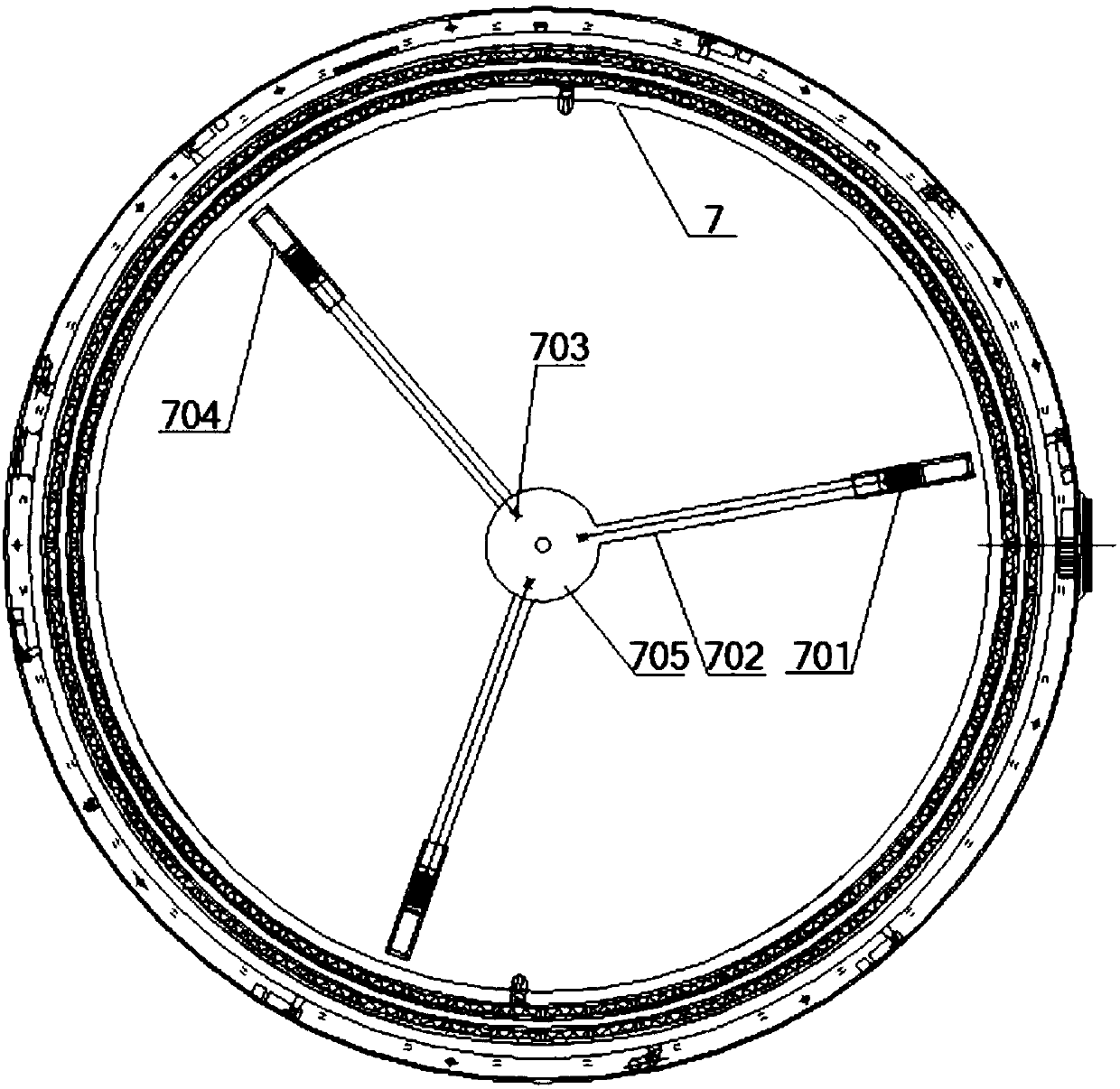

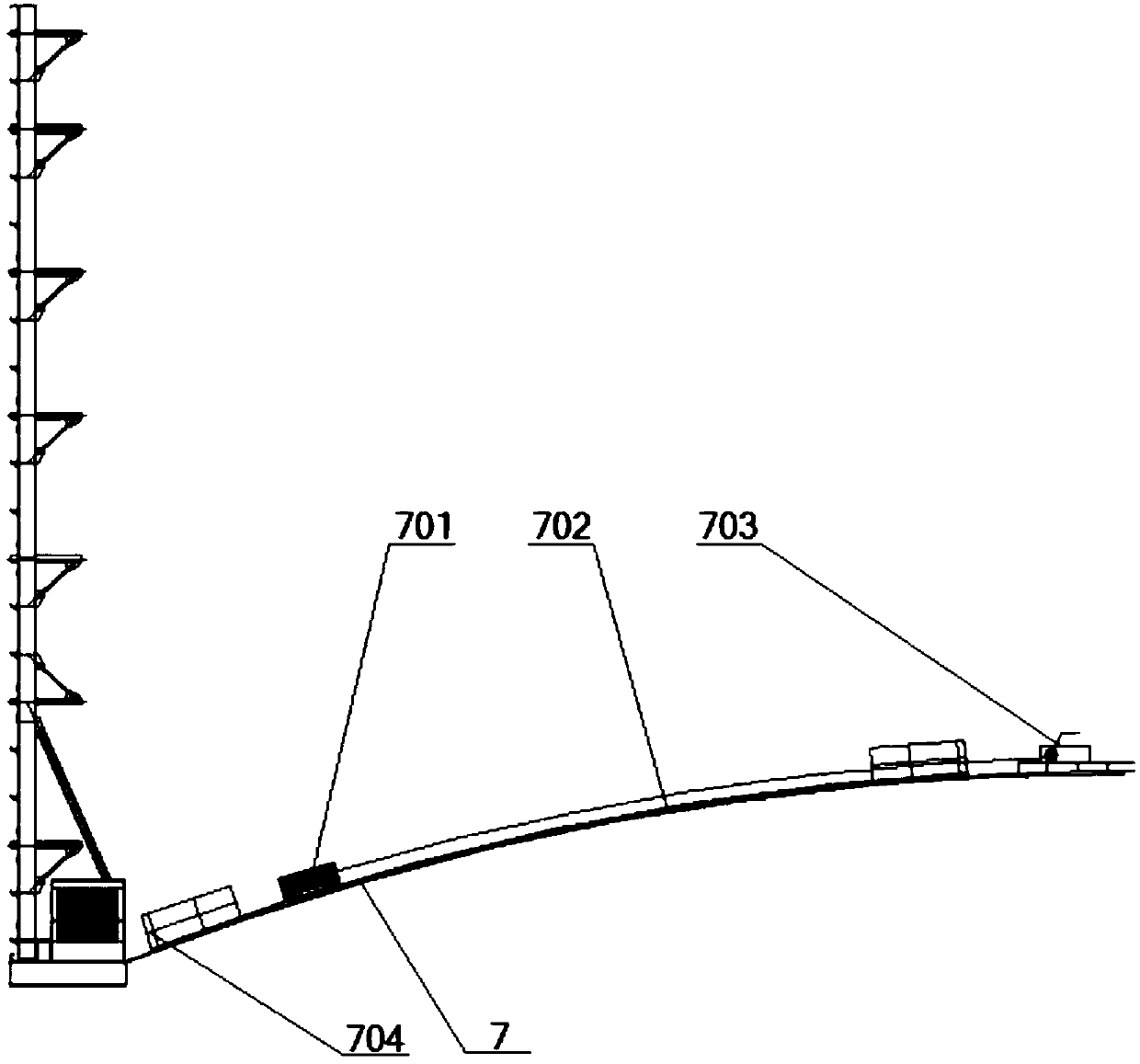

[0023] Such as figure 1 and figure 2 , the embodiment of the present invention provides a high-pressure gas cabinet, including a cabinet body and a piston 7 movably arranged in the cabinet body, a plurality of live counterweights 701 and a plurality of sliding guide rails 702 are arranged on the top of the piston 7, and the sliding The number of guide rails 702 is the same as that of the living counterweights 701 and they are arranged in one-to-one correspondence. Each of the living counterweights 701 is connected with a sliding drive mechanism 703 for driving them to slide on the corresponding sliding guide rails 702 .

[0024] The high-pressure gas cabinet provided in this embodiment drives the live counterweight 701 to slide on the piston 7 through the sliding drive mechanism 703, quickly and conveniently adjusts the position of the live counterweight 701, effectively improves the balanced and stable operation ability of the piston 7, and makes the high-pressure The skew ...

Embodiment 2

[0032] This embodiment provides a high-pressure gas cabinet, which is further optimized for the high-pressure gas cabinet provided in the above-mentioned embodiments. The high-pressure gas tank is a double-stage gas tank.

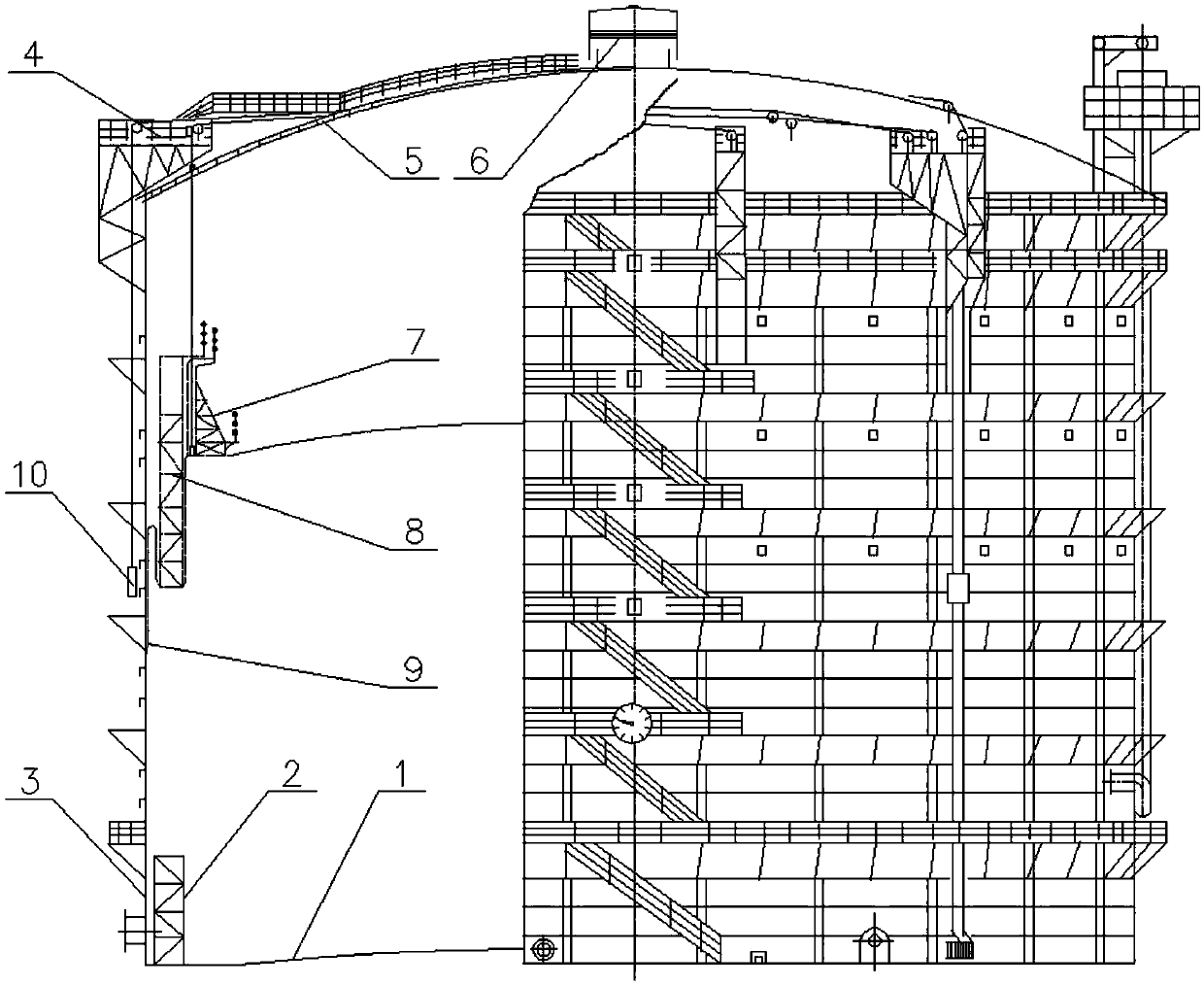

[0033] image 3 Shown is a schematic structural diagram of a traditional double-stage rubber membrane sealed dry-type gas cabinet. Generally, the cabinet body includes a cabinet bottom plate 1, a cabinet top plate 5 and side plates 3, and a piston 7 and a T baffle 8 are arranged inside the cabinet. Both the piston 7 and the T baffle 8 can move up and down in the cabinet; during the operation of the gas cabinet, the gas enters and exits by moving the piston 7 and the T baffle 8 up and down. When the T baffle 8 is not in contact with the piston 7 , supported by the T baffle bracket 2, after the piston 7 rises to contact with the T baffle 8, the T baffle 8 can be lifted to separate from the T baffle bracket 2; During the activity, there is a rubber membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com