CVT

A transmission and hydraulic technology, applied in transmissions, belts/chains/gears, fluid transmissions, etc., can solve the problem that the adaptability of working conditions is difficult to break through the limitation of power source capacity, the transmission range of mechanical structure is limited, and the overall structure requirements are relatively high. Advanced problems, to enhance the effect of overcoming overturning moment, large processing capacity and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

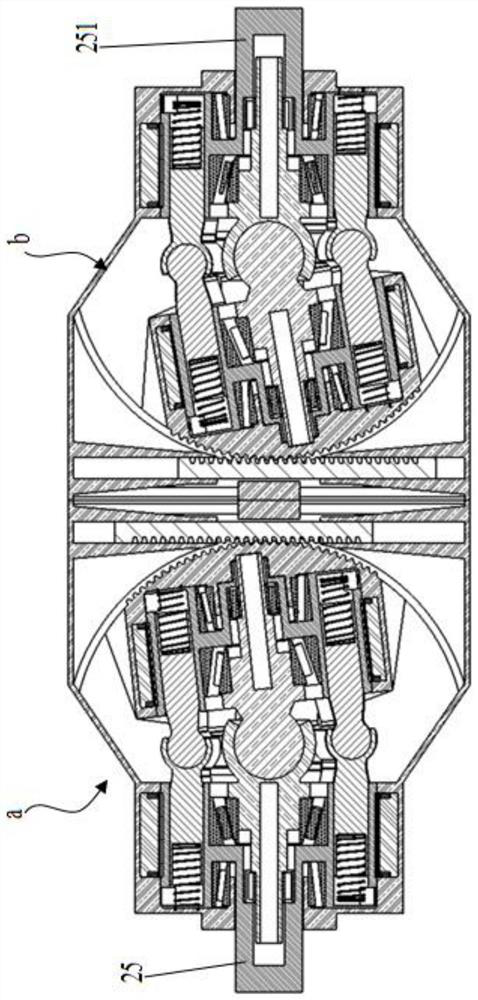

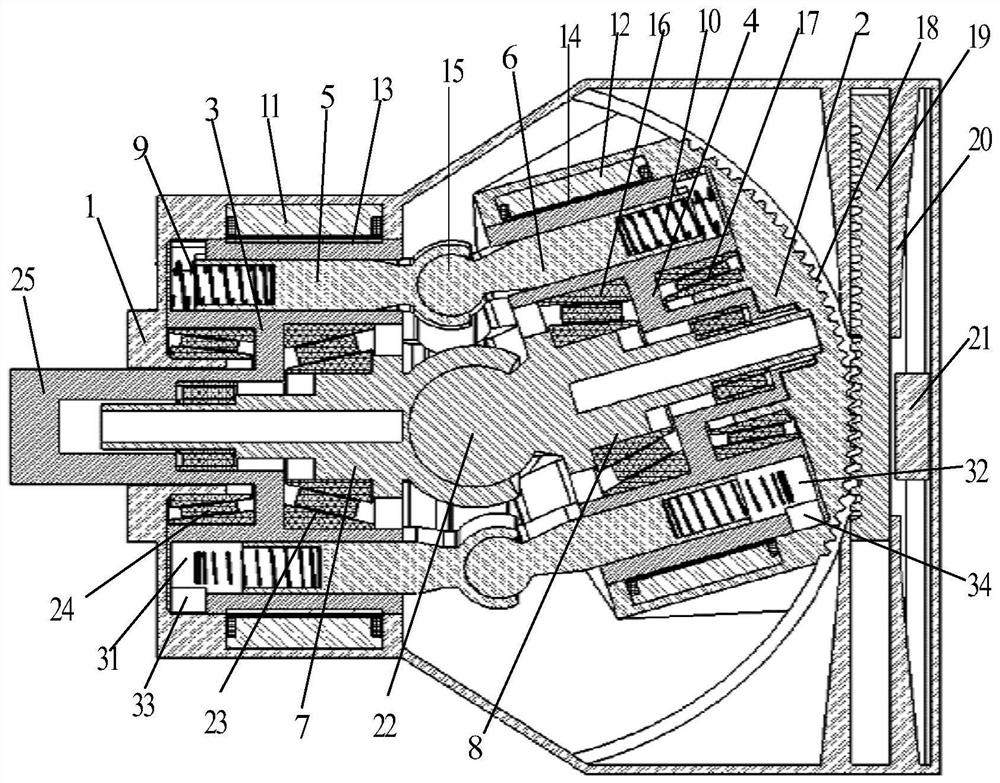

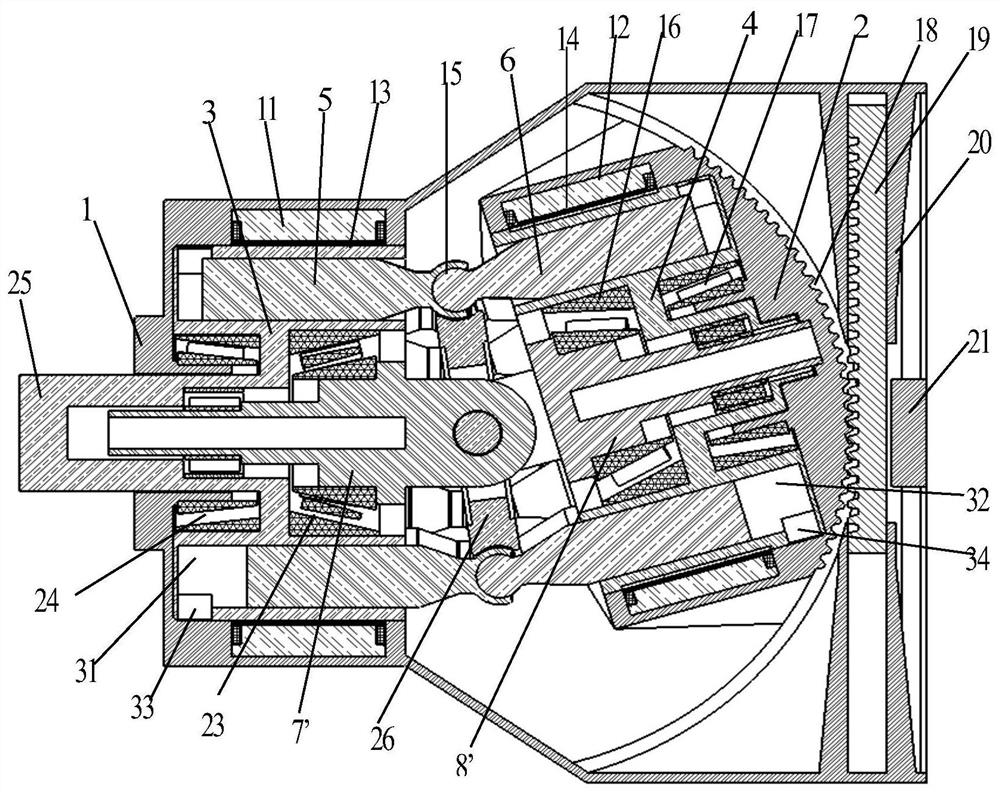

[0037]As shown in the figure, the continuously variable hydraulic transmission of the present invention includes an active pump a and a driven motor b. Both the active pump a and the driven motor b include a first base 1 and a second base 2. The first base 1 and the second base body 2 are correspondingly provided with a first accommodating cavity and a second accommodating cavity, and a first rotor cylinder and a second rotor cylinder are correspondingly rotatably arranged in the first accommodating cavity and the second accommodating cavity, The first rotor cylinder block and the second rotor cylinder block are respectively eccentrically provided with a first plunger cavity and a second plunger cavity; as shown in the figure, the first rotor cylinder block 3 and the second rotor cylinder block 4 respectively pass through corresponding The bearings (including angular contact bearings or thrust bearings) are arranged on the corresponding first base body 1 and second base body 2 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com