Special tooth PDC drill bit

A technology of special-shaped teeth and drill bits, which is applied in construction and other fields, can solve the problems of low mechanical penetration rate, increased drilling cost, and inability to drill, and achieve the effects of improving impact resistance, increasing the life of the drill bit, and strong anti-abrasion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

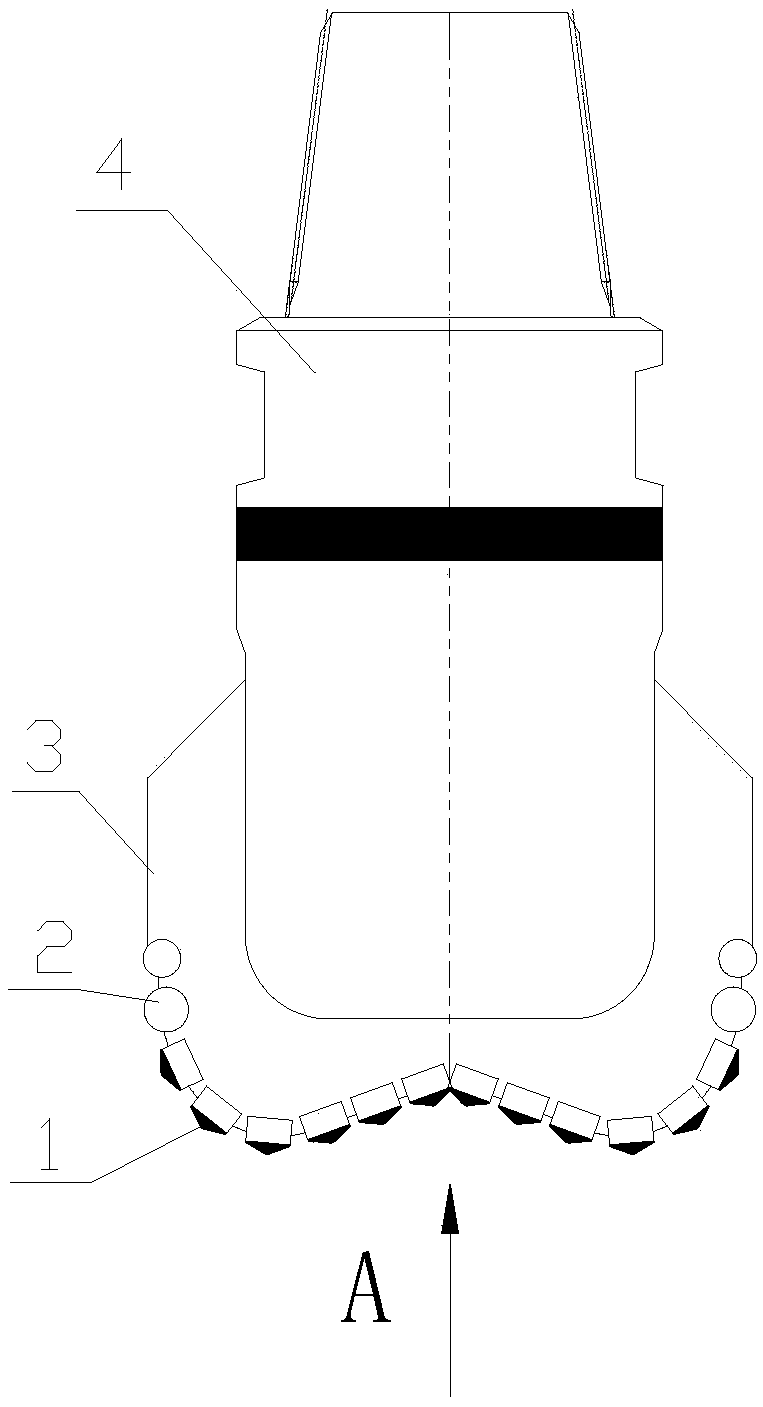

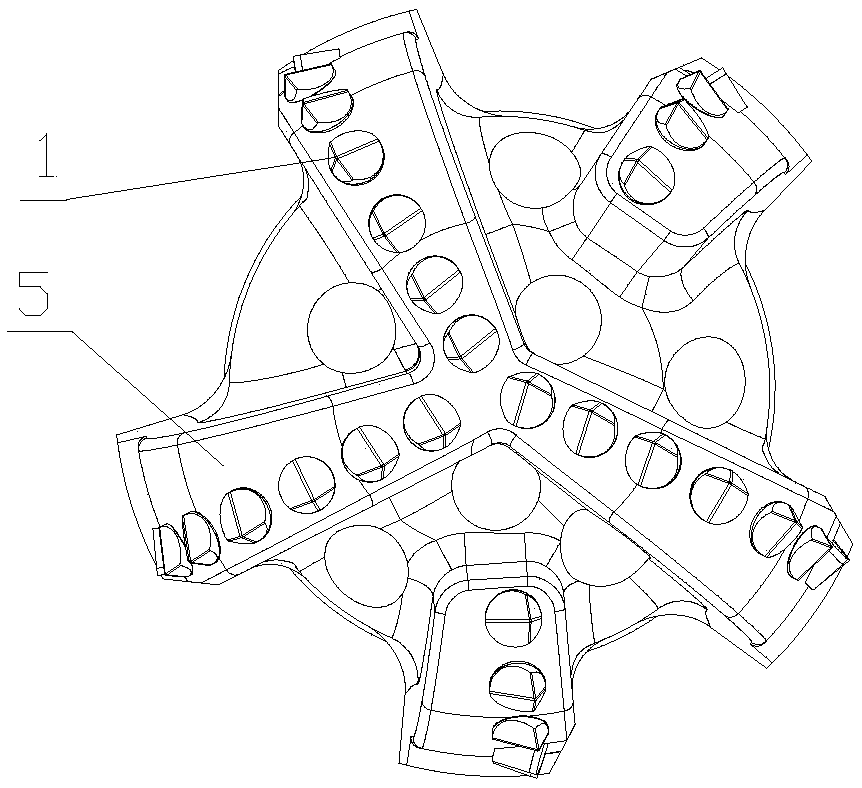

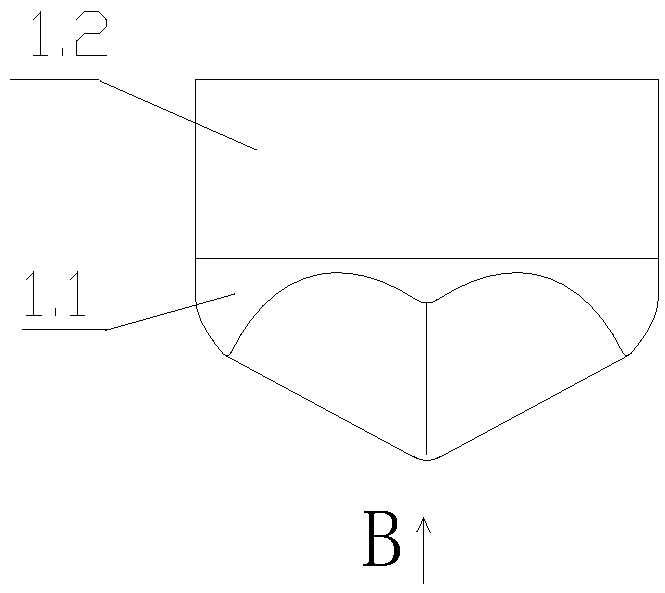

[0025] see Figure 1 to Figure 8 , the present invention includes a drill body and a joint 4, the drill body is installed on the joint 4, the drill body is composed of a plurality of blades 5 and a gauge 3, and the PDC teeth 2 are brazed on the blades 5. The key technology is to braze the PDC special-shaped tooth 1 on the blade 5. The PDC special-shaped tooth 1 is provided with a diamond layer 1.1 on the substrate 1.2, and the diamond layer 1.1 is arranged perpendicular to the respective normal 1.9 directions; the left and right sides of the diamond layer 1.1 The downward slope forms a symmetrical slope 1.7, and the symmetrical slopes intersect to form a median line 1.8. The front and rear sides of the diamond layer 1.1 slope downward to form an asymmetrical front and rear slopes, and the front slope forms a rapidly raised front ridge 1.4 , the rear slope forms a slowly descending posterior ridge 1.6, the intersection of the front slope and the rear slope forms a ridge line 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com