Standardization overall connection assembly-type concrete house structure and manufacturing method thereof

A concrete and prefabricated technology, which is applied to building components, building structures, walls, etc., can solve problems such as water leakage, difficult installation, and low production accuracy, and achieve the effects of reduced construction period, convenient construction, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

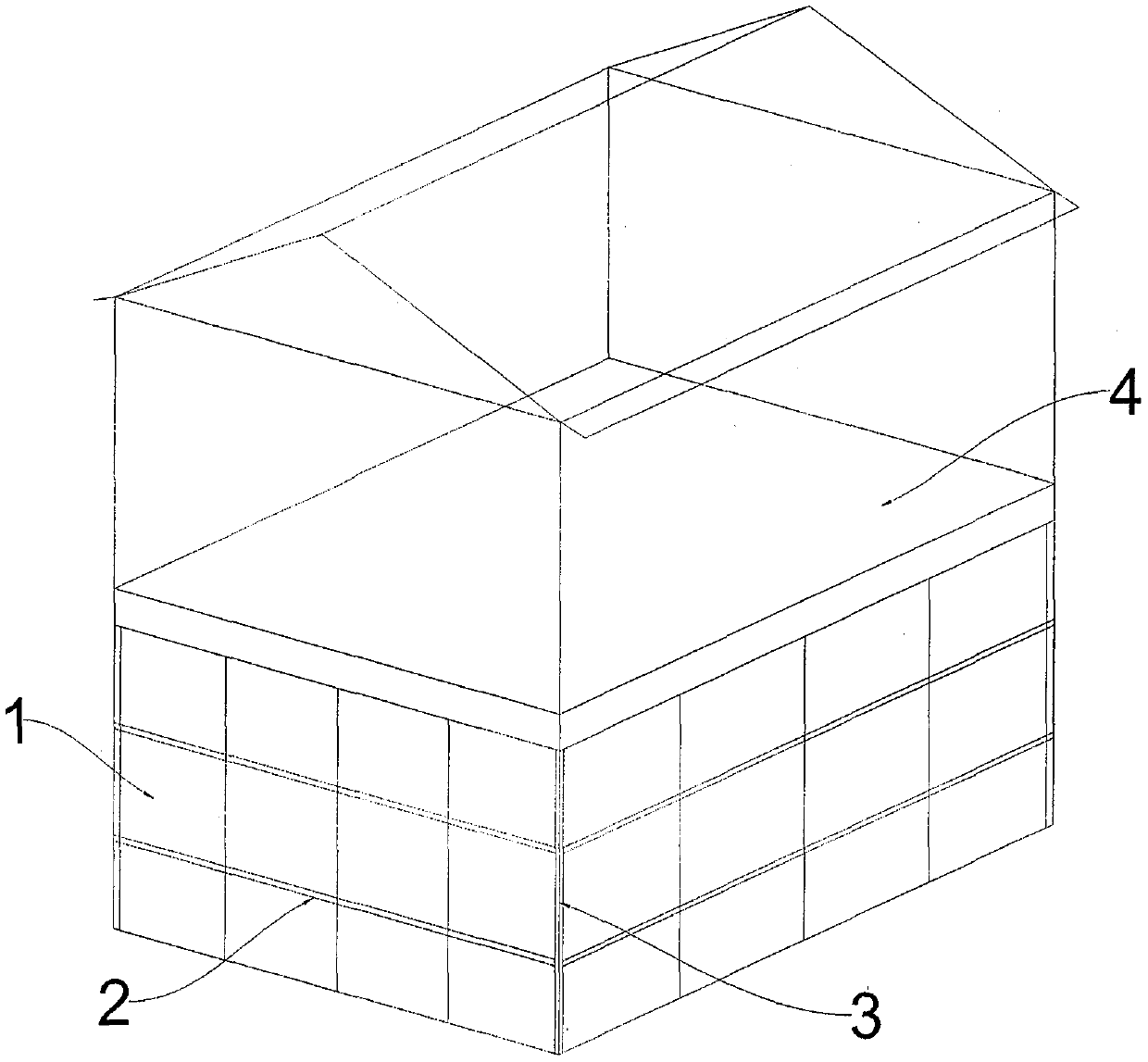

[0036] like figure 1 as shown, figure 1 It shows the standardized fully dry-connected prefabricated concrete house structure provided by the embodiment of the present invention, including a wall and a roof. For precast concrete slabs4.

[0037] Among them, the corner steel column 3 is a right-angled steel plate, and an installation hole 6 is set on it, which is mainly used for the corner connection between the precast concrete wall panel 1 and the precast concrete wall panel 1 and between the precast concrete wall panel 1 and the precast concrete layer 4 The position at is fixed, see Image 6 , Figure 7 , Figure 8 , which increases the stability of the overall structure, and its main purpose is to fix the steel beams to form the vertical columns in the three-dimensional skeleton.

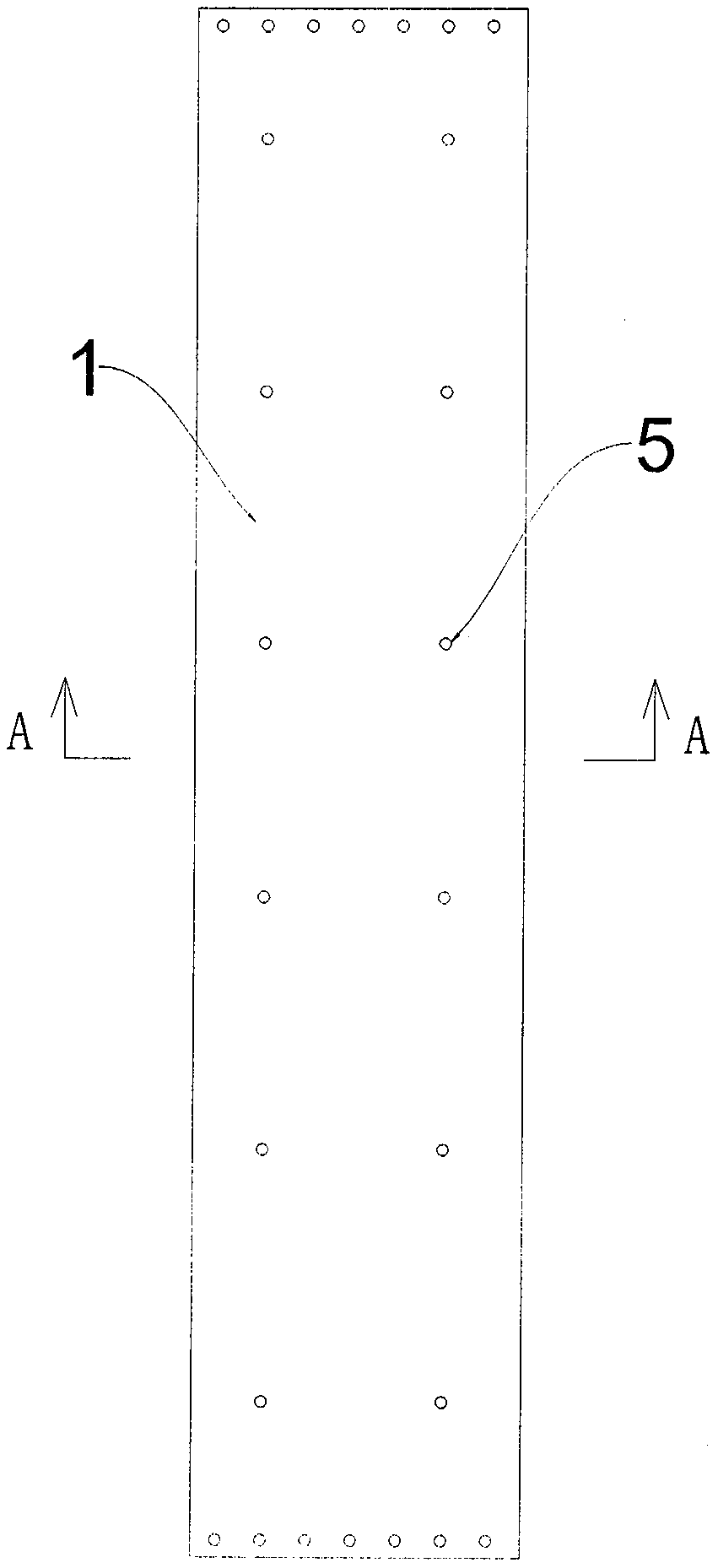

[0038] combine figure 2 , Figure 4 , Figure 5 As shown, a number of evenly distributed pre-embedded nuts 5 are set on the two end faces of the precast concrete wall panel 1, and a numbe...

Embodiment 2

[0048] Another embodiment of the present invention relates to a method for making a concrete house structure, comprising the steps of:

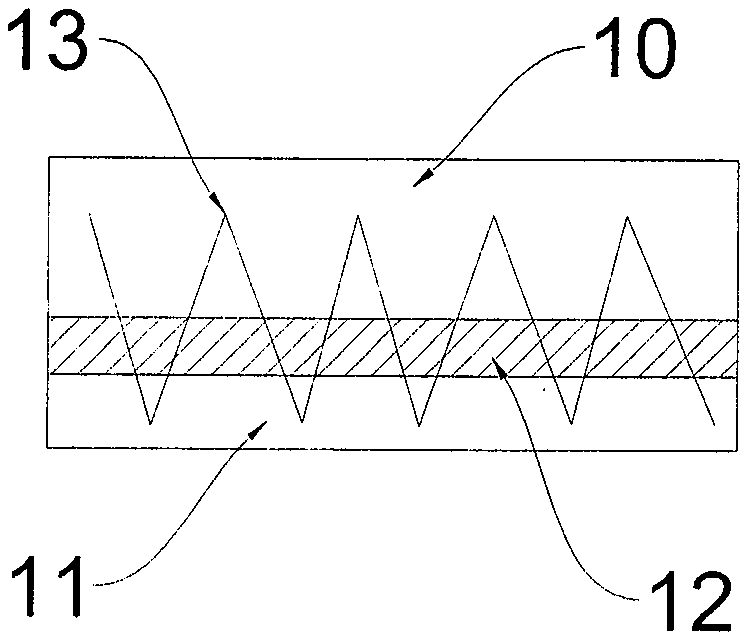

[0049] 1. Place the three-dimensional steel mesh 13 in the mold, set the scale marking line on the mold inner wall, and set the embedded nut 5 at the corresponding position, and pour concrete into the mold to form a concrete load-bearing layer 10, an insulating layer 12 and a concrete protection layer 11 , and set embedded nuts 5 at the corresponding positions on the protective layer, the prefabricated concrete layer 4 is formed by pouring molds, and the end faces are provided with floor through holes;

[0050] II. After the structure of pre-embedded concrete wall panels and pre-embedded concrete slabs is stable, make the foundation of the house according to the actual construction process, set a fixed structure on the foundation, arrange the prefabricated concrete wall panels 1 according to the construction requirements, and use horizontal st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com