Chisel holder

A technology of holder and chisel, which is used in roads, slitting machinery, construction, etc., can solve the problems of increased wear of the disc and chisel holder, and achieve the effect of improving the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

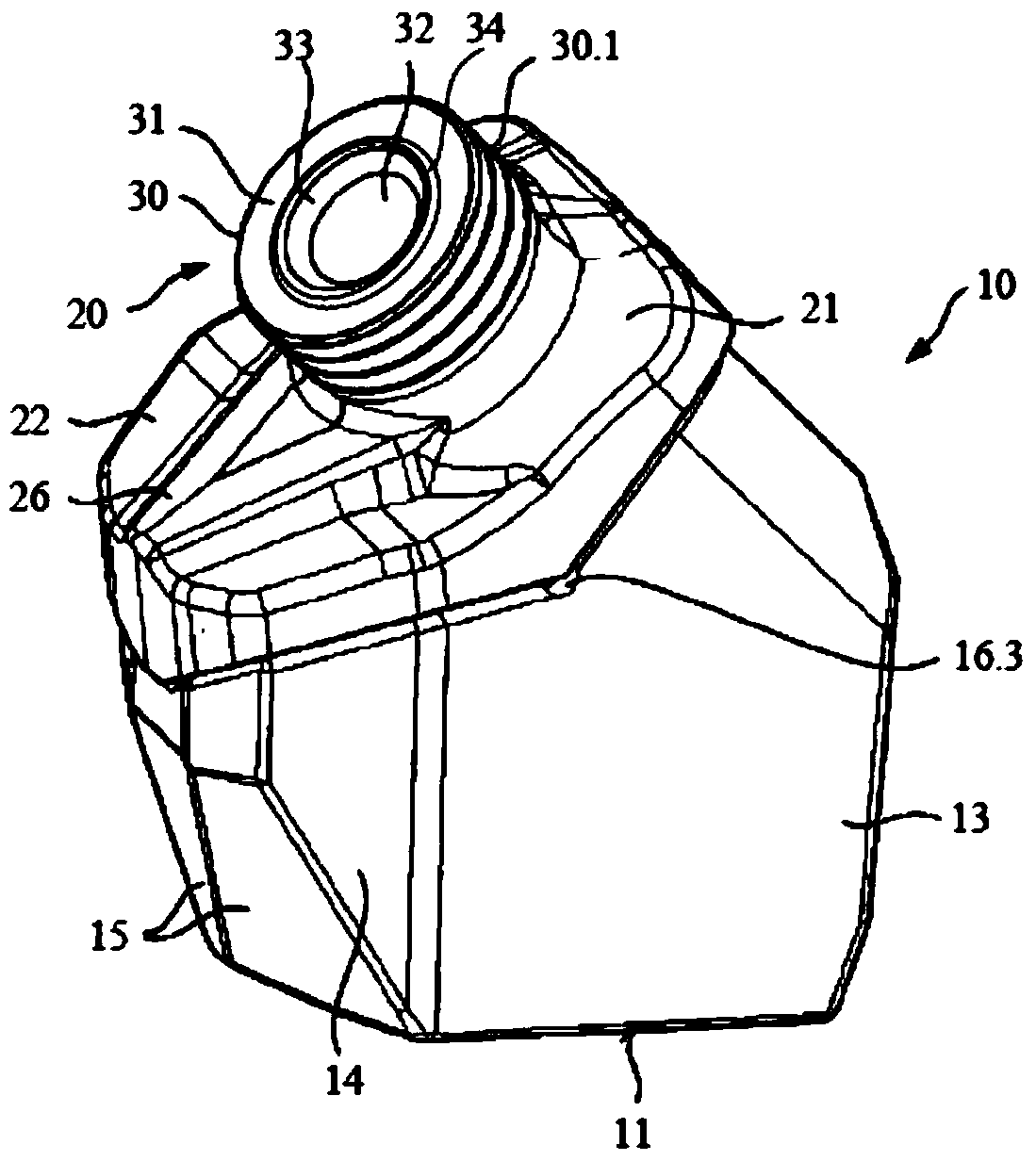

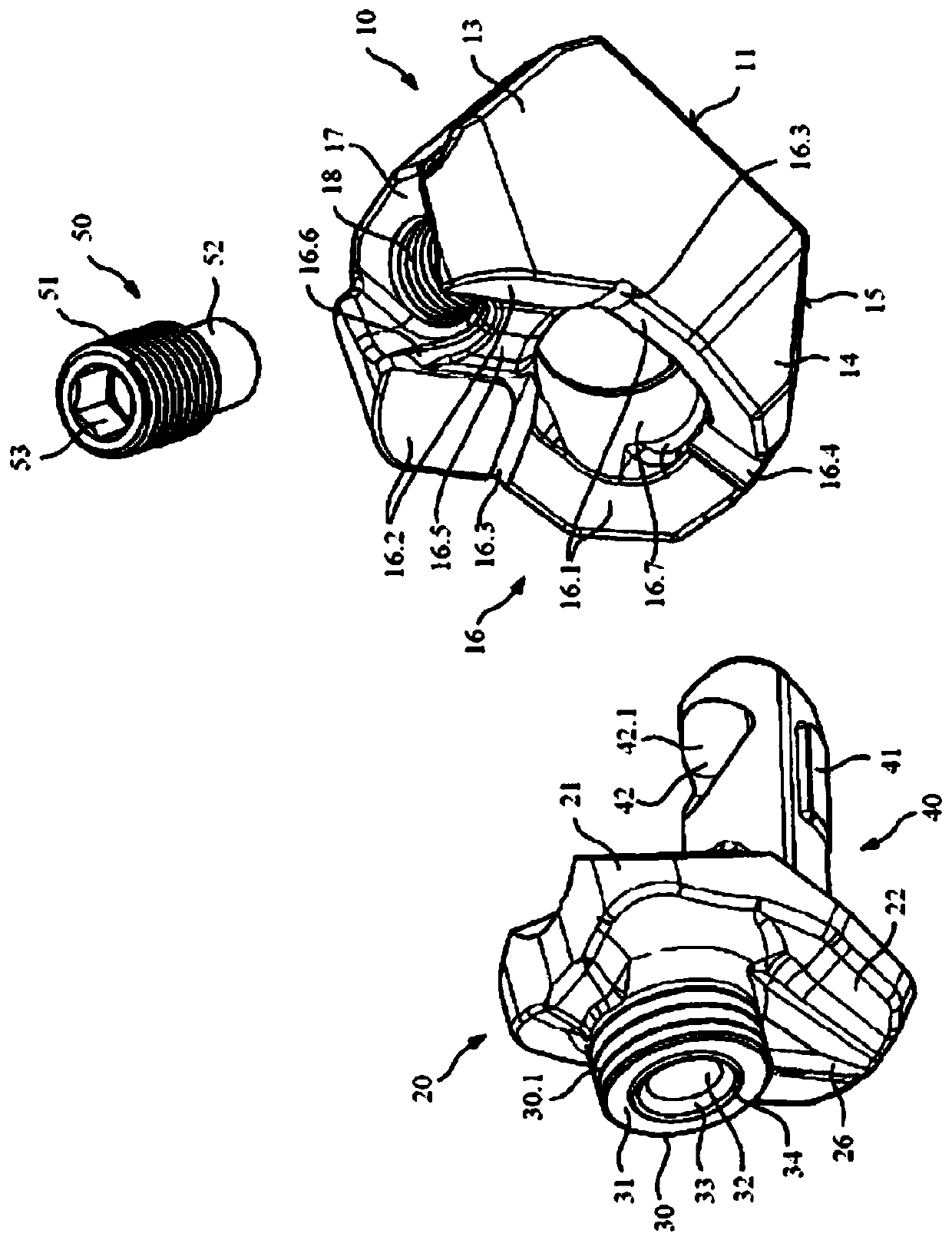

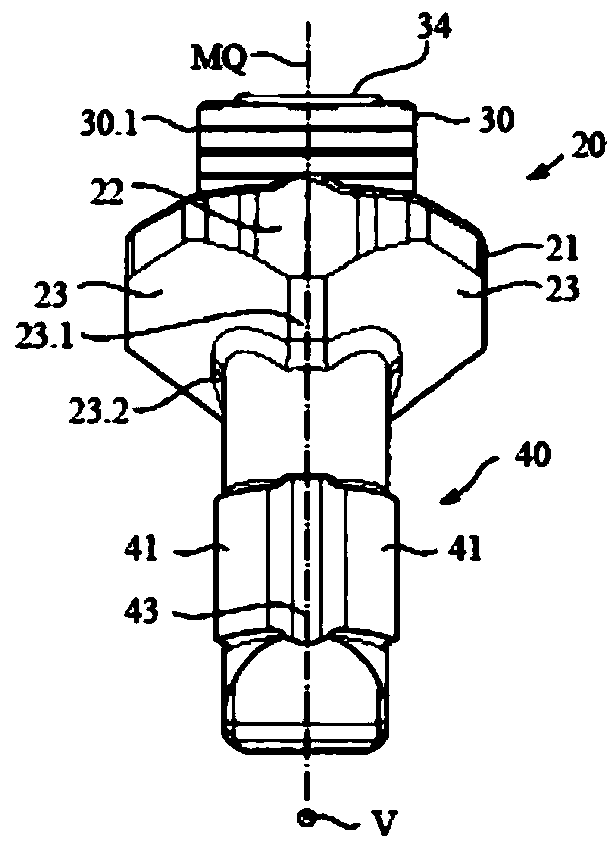

[0031] figure 1 A bit holder 20 detachably connected to the base frame 10 is shown in a perspective side view. Opposite the bit holder 20 , the base frame 10 is closed by a concavely formed lower closure side 11 . The base frame 10 is fastened with this closed side 11 to a not shown milling drum of a ground working machine (here a milling machine). In order to be able to transmit high forces, the chassis 10 is preferably welded to the milling drum. The base body 13 of the base frame 10 has at the front in the working direction two inclined surfaces 15 arranged at an angle symmetrical to one another with respect to the longitudinal center plane of the base frame 10 . Connected to this lateral slope are two inclined surfaces 14 arranged in mirror-symmetrical angle with respect to the longitudinal median plane of the undercarriage 10 , only one of which is visible in this perspective view. The inclined surface 14 merges at an angle into the side of the base body 13 . The side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com