A kind of preparation method of crude oil viscosity reducing material and crude oil viscosity reducing material

A crude oil and graphene technology, applied in chemical instruments and methods, drilling compositions, physical/chemical process catalysts, etc., can solve the problems of poor viscosity reduction effect, high dosage, low temperature deactivation, etc., and achieve viscosity reduction efficiency High, low temperature, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

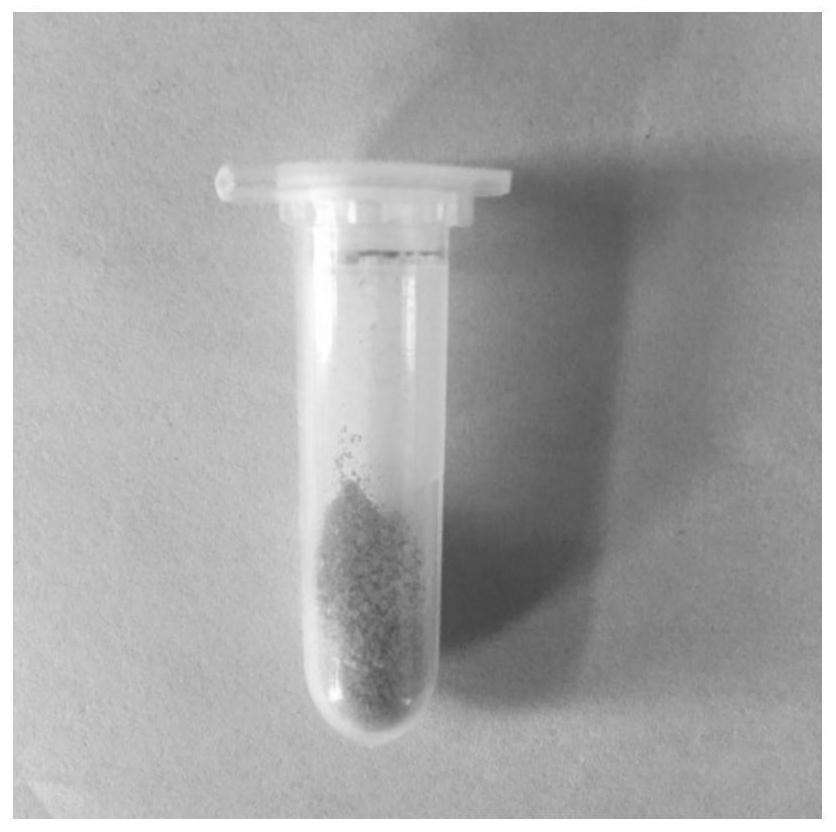

[0034] The preparation and use process of crude oil viscosity reducing material are as follows:

[0035] (1) Taking by weighing a solid content of 2.51% graphene oxide jelly is uniformly dispersed in water, and in the graphene oxide jelly, the graphene oxide content is 0.0075g;

[0036] (2) Under normal temperature stirring, 0.17g Co(NO 3 ) 2 6H2O, 0.17g Ni(NO 3 ) 2 ·6H 2 O and 0.09g NaOH are slowly added in the above solution;

[0037] (3) Add 50 μL N 2 h 4 , keep stirring for 3h;

[0038] (4) Transfer to a high-pressure reactor and react at 180° C. for 12 hours to obtain the crude oil viscosity-reducing material;

[0039] (5) Add the crude oil viscosity-reducing material and 188 μL of toluene to 15 g of crude oil, the crude oil viscosity-reducing material accounts for 0.5 wt % of the crude oil, and react at 180° C. for 12 hours to carry out the viscosity-reducing reaction.

[0040] The crude oil viscosity-reducing material in this example is composed of 45% elementa...

Embodiment 2

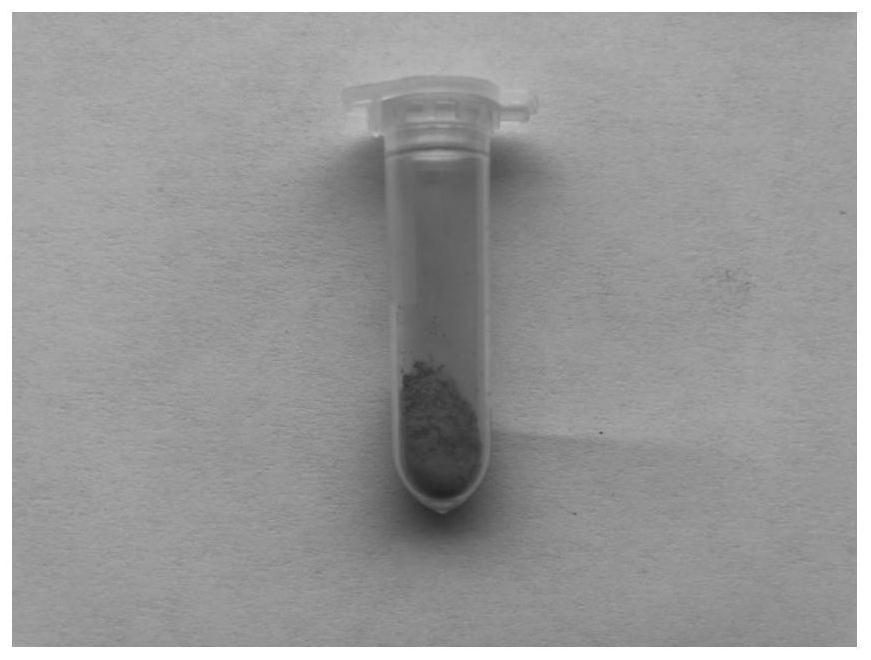

[0042] The preparation and use process of crude oil viscosity reducing material are as follows:

[0043] (1) Taking by weighing a solid content of 2.51% graphene oxide jelly is uniformly dispersed in water, and in the graphene oxide jelly, the graphene oxide content is 0.0075g;

[0044] (2) Under normal temperature stirring, 0.33g CoCl 2 ·6H 2 O and 0.09g NaOH are slowly added in the above solution;

[0045] (3) Add 50 μL N 2 h 4 , keep stirring for 3h;

[0046] (4) Transfer to a high-pressure reactor and react at 180° C. for 12 hours to obtain the crude oil viscosity-reducing material;

[0047] (5) Add 0.5% crude oil viscosity-reducing material and 188 μL toluene to 15 g crude oil, and react at 180° C. for 12 hours to carry out the viscosity-reducing reaction.

[0048] The crude oil viscosity-reducing material in this example is composed of 90% simple Co and 10% carrier RGO, and its viscosity-reducing effect is shown in Table 1.

Embodiment 3

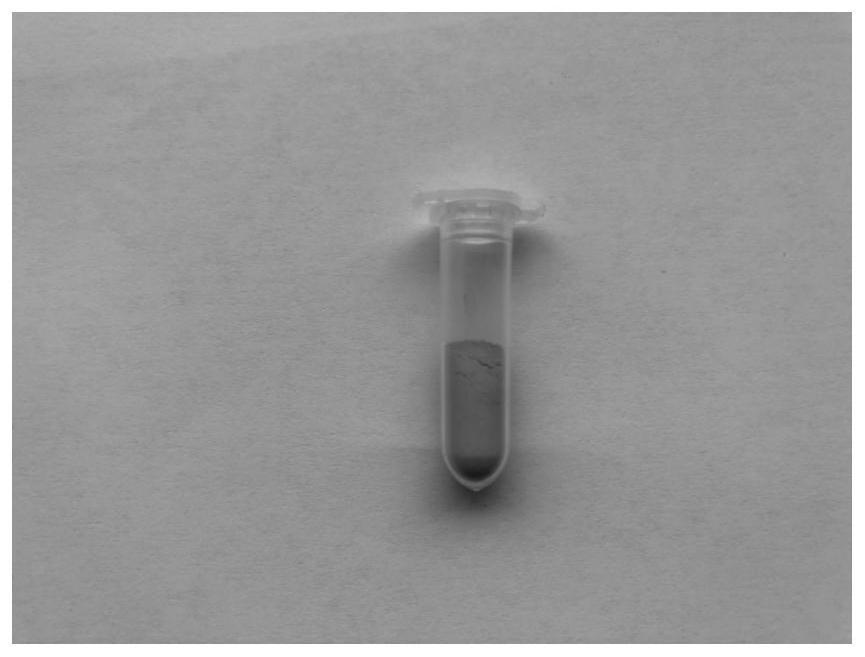

[0050]The crude oil viscosity reducing catalyst is composed of 50% elemental Co and 50% elemental Ni. The preparation and use process are as follows:

[0051] (1) Under normal temperature stirring, 0.17g Co(NO 3 ) 2 ·6H 2 O, 0.17g Ni(NO 3 ) 2 ·6H 2 O and 0.09g NaOH are slowly added in the above solution;

[0052] (2) Add 50 μL N to the above system 2 h 4 , keep stirring for 3h;

[0053] (3) Transfer to an autoclave and react at 180°C for 12 hours to obtain a viscosity-reducing catalyst;

[0054] (4) Add 0.5% viscosity-reducing catalyst and 171 μL of toluene to 13.7 g of crude oil, and react at 180° C. for 12 hours to carry out the viscosity-reducing reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com