Wood grabbing operation mechanism adopting multi-connecting-rod series-parallel structure

A technology of series structure and working mechanism, applied in the direction of manipulator, program control manipulator, manufacturing tool, etc., can solve the problems of large rotational inertia of arm, decreased dynamic performance, large accumulated error, etc. The effect of improving the rigidity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

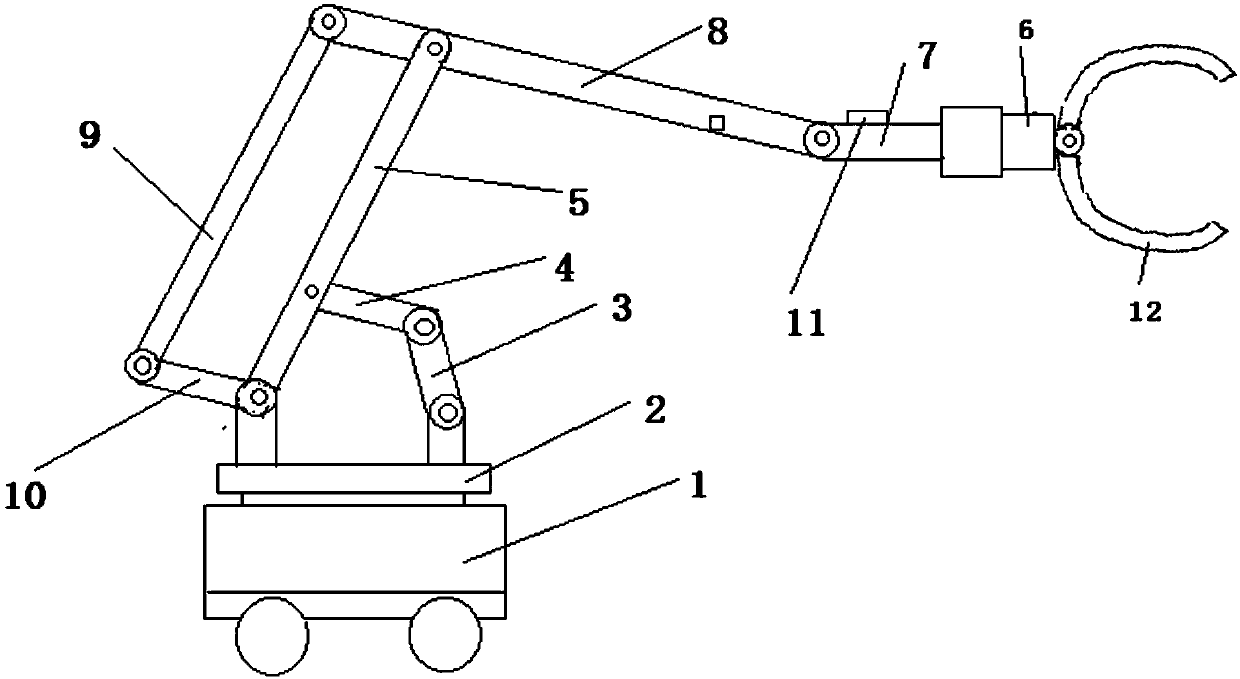

[0006] A wood-grabbing operation mechanism adopting a multi-link parallel structure in the present invention includes a base 1, a rotary platform 2, a first active rod 3, a second active rod 10, a boom 5, a boom connecting rod 4, Middle arm connecting rod 9, middle arm 8, small arm 7, inclination detector 11 and driving device; one end of the first active rod 3 is connected to the rotary platform 2, and the other end of the first active rod 3 is connected to one end of the big arm connecting rod 4 connection, the other end of the boom connecting rod 4 is connected with one end of the boom 5, one end of the second active rod 10 is connected with the rotary platform 2, the other end of the second active rod 10 is connected with the middle arm connecting rod 9, and the other end of the middle arm connecting rod 9 One end of the middle arm 8 is connected, one end of the big arm 5 is connected with the rotary platform 2, the other end of the big arm 5 is connected with the middle ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com