A kind of manufacturing method of ceramic core free end wax cap

A technology of ceramic cores and manufacturing methods, which is applied in the direction of cores, manufacturing tools, casting molds, etc., can solve problems such as uneven gaps, increased production costs, broken cores, etc., and achieve high consistency of wax layer thickness and uniform gaps. The effect of controlling and reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

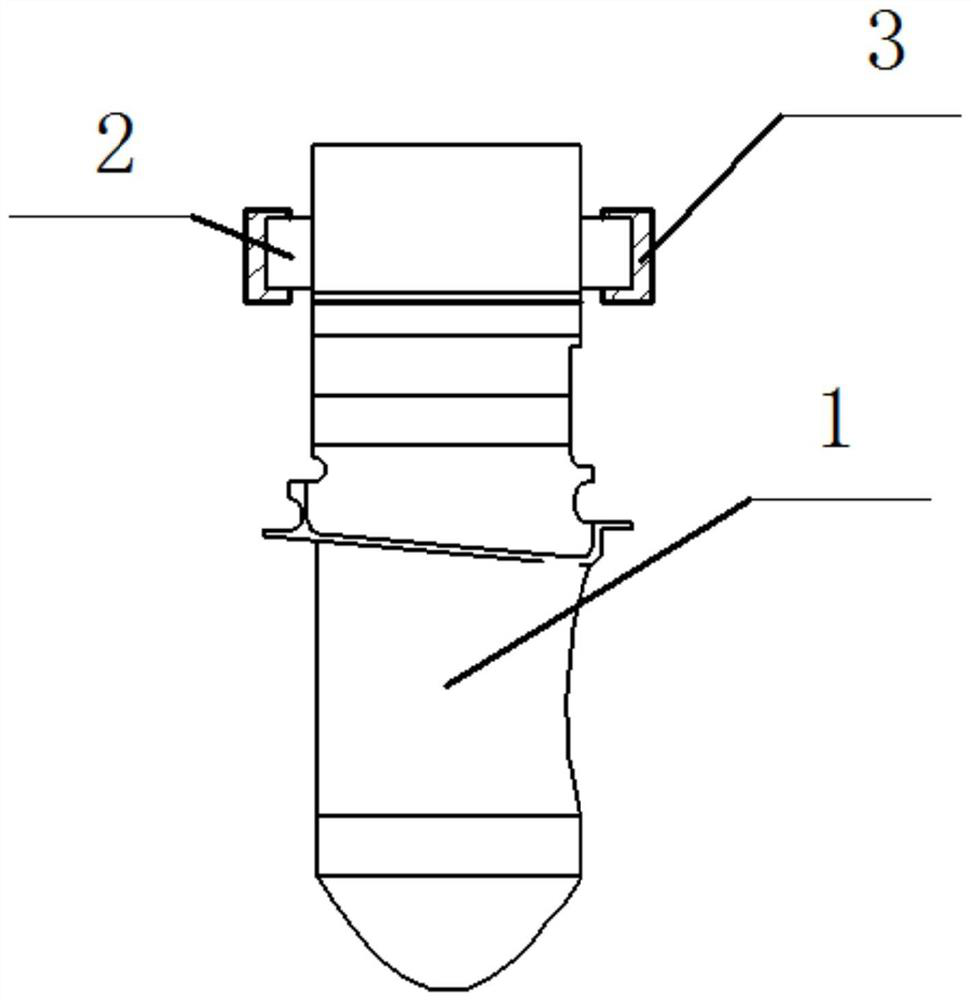

[0035] Embodiment 1: The steps of the method for making the free end wax cap of a ceramic core of a certain turbine working blade are as follows:

[0036] 1) Design the free end of the ceramic core: design the production plan for the free end of the ceramic core according to the structure of the working blade, the structure of the ceramic core, the metal material, and the pouring method, and determine that the tip of the blade is the fixed end, and the tenon is the free end. Wax caps are made at both ends of the ceramic core beam with a thickness of 0.5mm.

[0037] 2) According to the free end of the ceramic core designed in 1), process the space required by the size of the wax cap at the free end wax cap of the ceramic core corresponding to the inner cavity of the existing casting wax mold mold;

[0038] 3) Put the ceramic core into the casting wax mold as required, inject the wax material according to the wax mold pressing parameters and maintain the pressure, open the mold,...

Embodiment 2

[0042] Embodiment 2: The steps of the method for making the free end wax cap of a ceramic core of a certain turbine guide vane are as follows:

[0043] 1) Design the free end of the ceramic core: Design the manufacturing plan for the free end of the ceramic core according to the structure of the guide vane, the structure of the ceramic core, the metal material, and the pouring method, and determine that the lower edge plate of the guide vane is the fixed end, and the upper edge plate is For the free end, make a wax cap at the end of the ceramic core at the upper edge plate, with a thickness of 0.5mm.

[0044] 2) According to the free end of the ceramic core designed in step 1, process the space required by the size of the wax cap at the free end wax cap of the ceramic core corresponding to the inner cavity of the existing casting wax mold mold;

[0045] 3) Put the ceramic core into the casting wax mold as required, inject the wax material according to the wax mold pressing par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com