Insulator cleaning robot

A technology for cleaning robots and insulators, applied in the field of cleaning robots, can solve problems such as potential safety hazards, insulator flashover discharge, increased economic costs, etc., and achieve the effect of liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

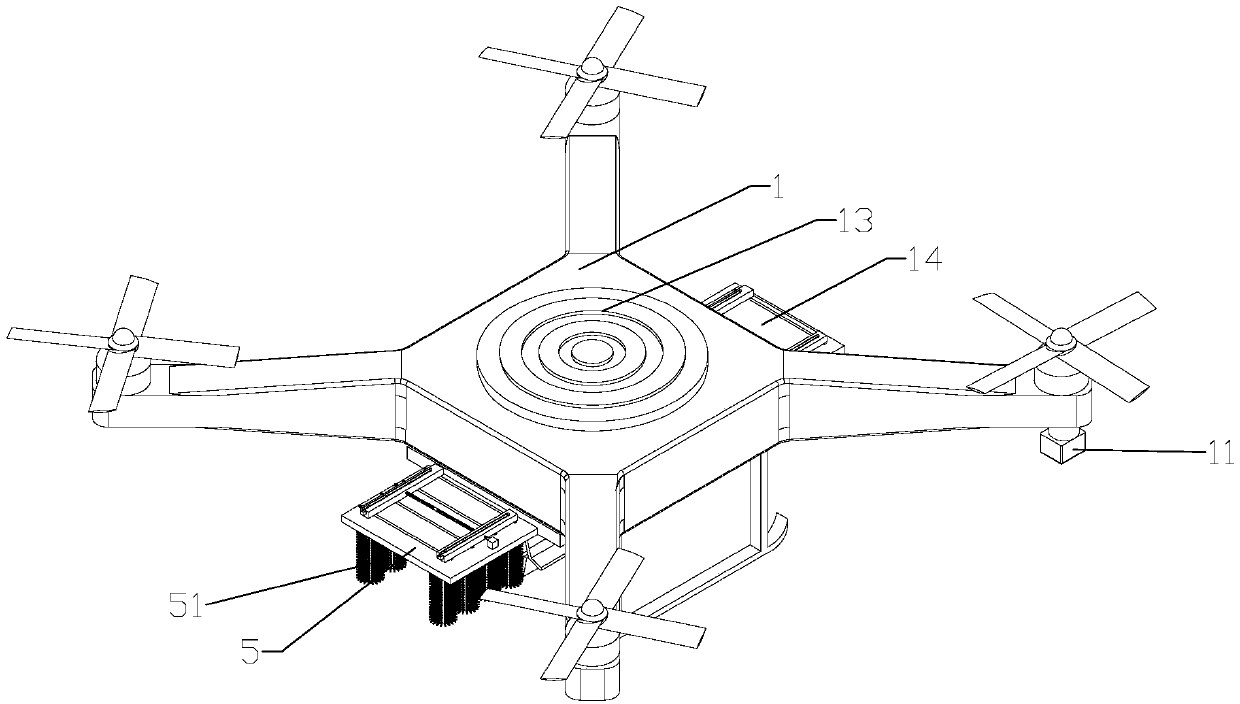

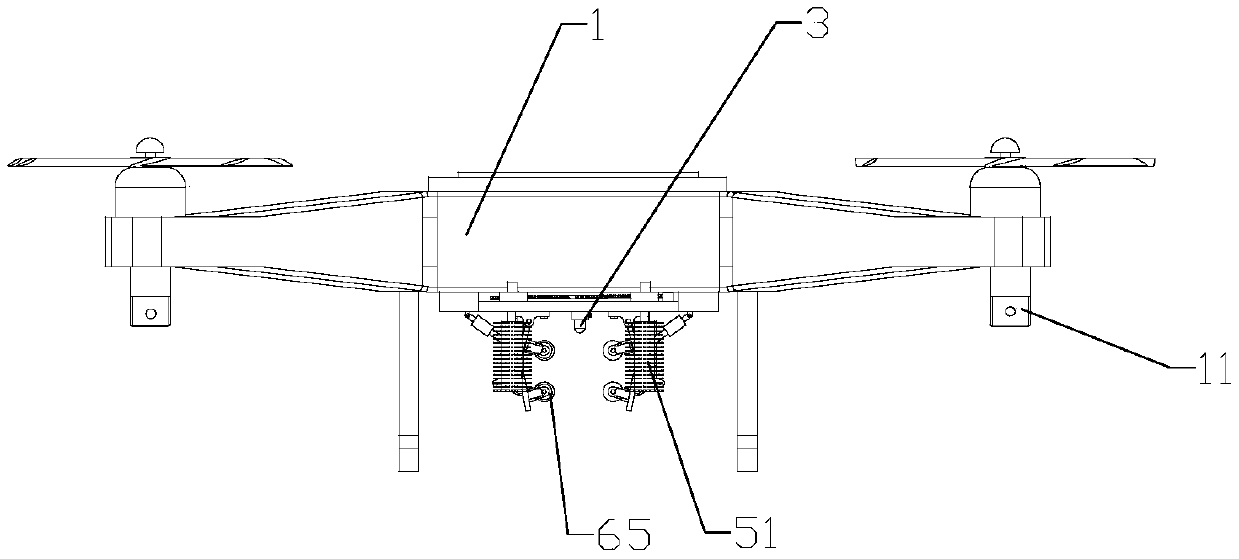

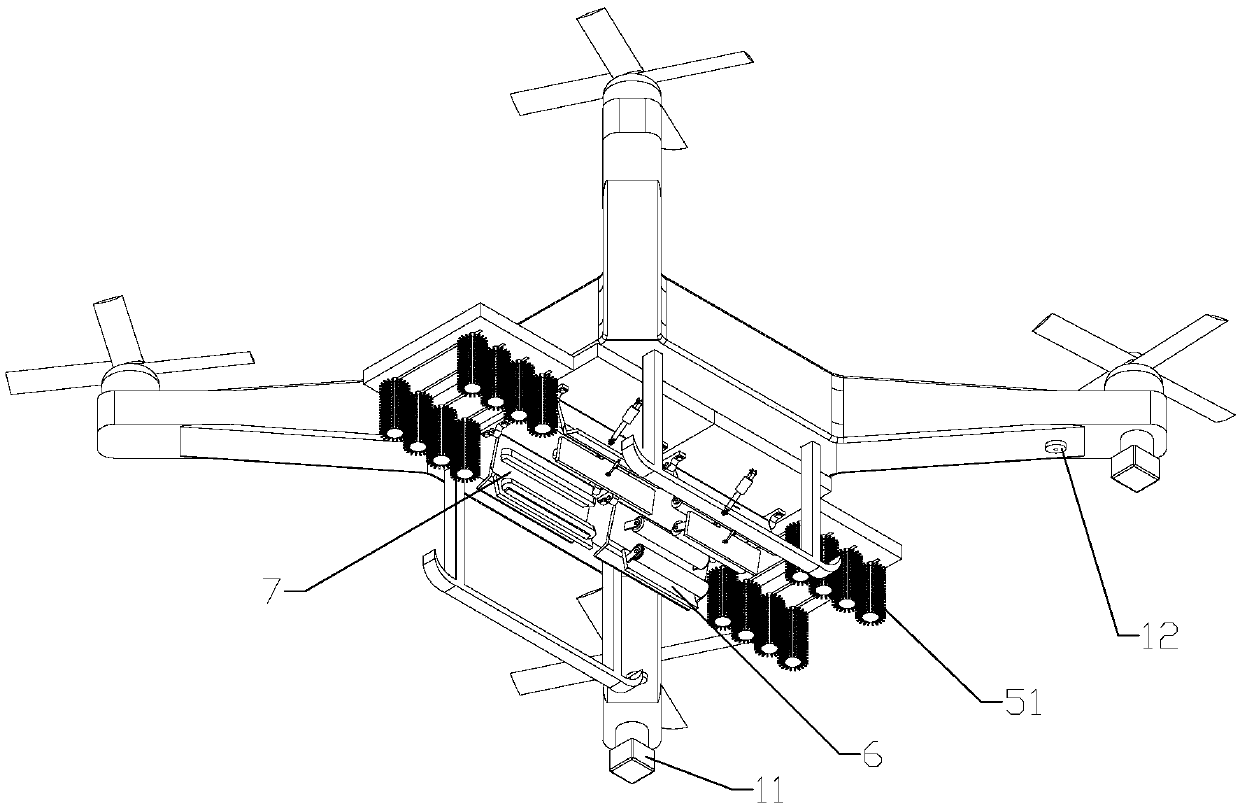

[0039] as attached figure 1 to attach Figure 16 As shown, the present invention comprises aircraft 1, and aircraft 1 is provided with controller I, camera 11, image processor, memory, data transmission module, foreign object radar and navigation system, camera 11 is connected with image processor, image processor and data The transmission module is connected, and the image processor, memory, foreign object radar and navigation system are respectively connected to the controller I. The foreign object radar is used to avoid obstacles. There are two cameras 11, which are respectively symmetrically arranged on the wings on both sides of the front end of the aircraft 1. On the base at the lower end, the camera 11 transmits the pictures taken to the image processor, and the image processor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com