Reuse method of camellia oleifera shell

A technology of camellia oleifera shells and seafood mushrooms is applied in the directions of botanical equipment and methods, application, horticulture, etc., which can solve the problems of complex methods of multi-level utilization of camellia oleifera shells, not fully reflecting the value of camellia oleifera shells, and single reuse method. The effect of cultivation cycle, easy promotion and shortening of fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

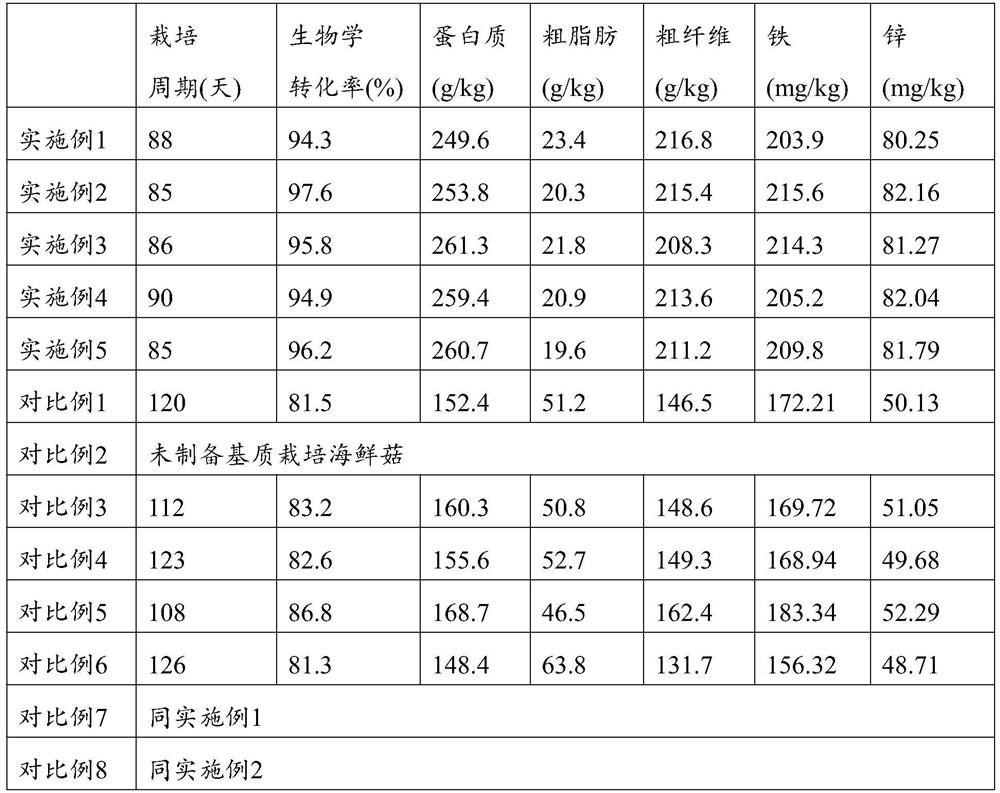

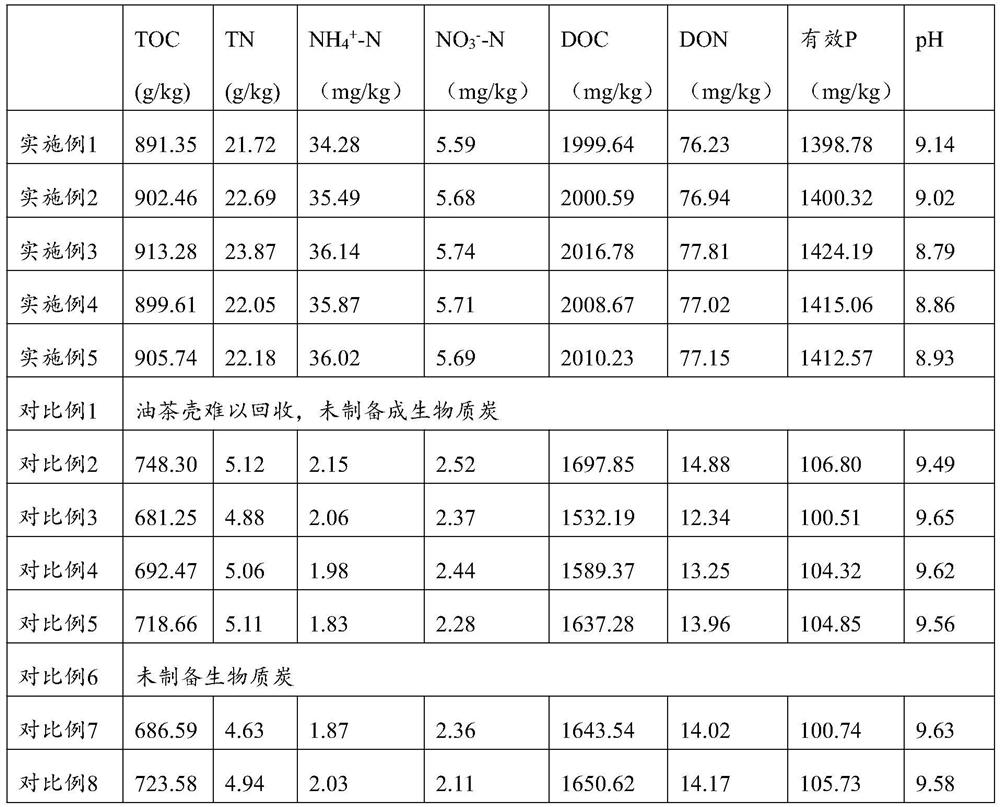

Examples

Embodiment 1

[0041] The camellia oleifera shell was used to prepare the substrate for cultivating seafood mushrooms, and after the seafood mushrooms were cultivated and harvested, the camellia oleifera shell was recovered to prepare biochar.

[0042] The method for preparing the matrix is:

[0043] S1. Crush 55 parts by weight of Camellia oleifera husks into a particle size of 6-8 mm, add 15 parts by weight of seafood mushroom residue powder with a particle size of 50-52 μm and 200 parts by weight of water, stir at 150 r / min for 50 min, seal, and heat to 45°C, place at constant temperature for 2 hours, cool to room temperature and place for 5 hours to obtain the standby feed liquid;

[0044] S2. Mix 10 parts by weight of plant ash and 10 parts by weight of wheat bran, then add it to the feed liquid obtained in step S1, stir at 150 r / min for 30 minutes, add 3 parts by weight of white sugar, continue stirring for 10 minutes, and adjust the pH with calcium hydroxide to 7.0, continue to stir ...

Embodiment 2

[0050] The camellia oleifera shell was used to prepare the substrate for cultivating seafood mushrooms, and after the seafood mushrooms were cultivated and harvested, the camellia oleifera shell was recovered to prepare biochar.

[0051] The method for preparing the matrix is as follows: S1. Crush 60 parts by weight of camellia oleifera shells into a particle size of 6-8 mm, add 20 parts by weight of seafood mushroom residue powder with a particle size of 55-60 μm and 250 parts by weight of water, and use 200 r / min Stir for 40 minutes, seal, heat to 50°C, place at a constant temperature for 3 hours, cool to room temperature and place for 6 hours to obtain a spare feed liquid;

[0052] S2. Mix 12 parts by weight of plant ash and 12 parts by weight of wheat bran, then add to the feed liquid obtained in step S1, stir at 200r / min for 25min, add 4 parts by weight of white sugar, continue stirring for 10min, and adjust the pH with calcium hydroxide To 7.3, continue to stir for 15 ...

Embodiment 3

[0058] The camellia oleifera shell was used to prepare the substrate for cultivating seafood mushrooms, and after the seafood mushrooms were cultivated and harvested, the camellia oleifera shell was recovered to prepare biochar.

[0059] The method for preparing the matrix is as follows: S1. Crush 65 parts by weight of camellia oleifera husks into particle diameters of 6-8mm, add 25 parts by weight of seafood mushroom residue powder with a particle size of 90-100 μm and 300 parts by weight of water, and use 250r / min Stir for 30 minutes, seal, heat to 55°C, place at constant temperature for 4 hours, cool to room temperature and place for 8 hours to obtain the standby feed liquid;

[0060] S2. Mix 15 parts by weight of plant ash and 15 parts by weight of wheat bran, then add to the feed liquid obtained in step S1, stir at 250r / min for 20min, add 5 parts by weight of white sugar, continue stirring for 15min, and adjust the pH with calcium hydroxide To 7.6, continue stirring for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com