Three-dimensional ordered porous structure hydrogel-supported sulfur particle composite material and preparation method thereof, cathode for lithium-sulfur battery, lithium-sulfur battery

A three-dimensional ordered, porous structure technology, applied in the field of nanomaterials, can solve problems that hinder the practical application of lithium-sulfur batteries, polysulfide shuttle phenomenon, low conductivity, etc., to improve electron transport capabilities, improve battery performance, and good conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

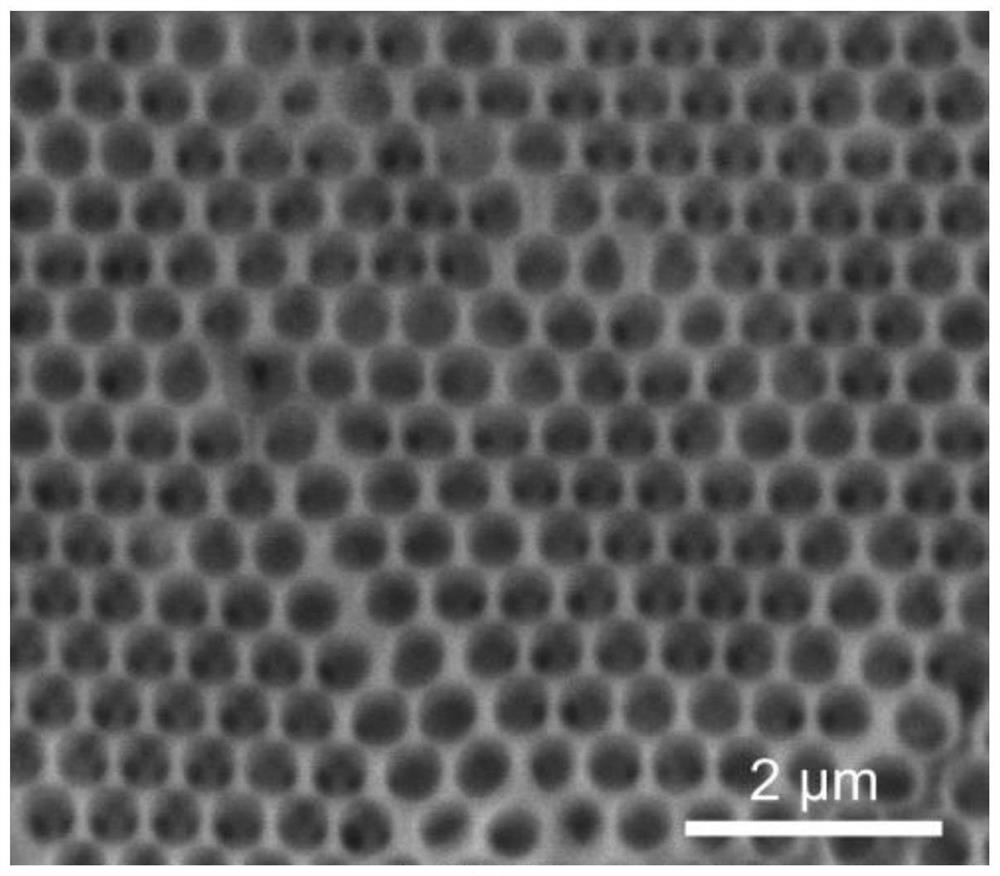

[0043] A method for preparing a three-dimensional ordered porous structure hydrogel-loaded sulfur particle composite material, comprising the following steps:

[0044] A. Dissolve 1 ml of aniline and 1 ml of phytic acid in 10 ml of water, stir in an ice-water bath for 10 minutes, add 20 ml of ammonium persulfate solution containing 3 g of ammonium persulfate, and continue stirring for 10 minutes in an ice-water bath at 0°C , to obtain a uniformly mixed conductive hydrogel polyaniline sol.

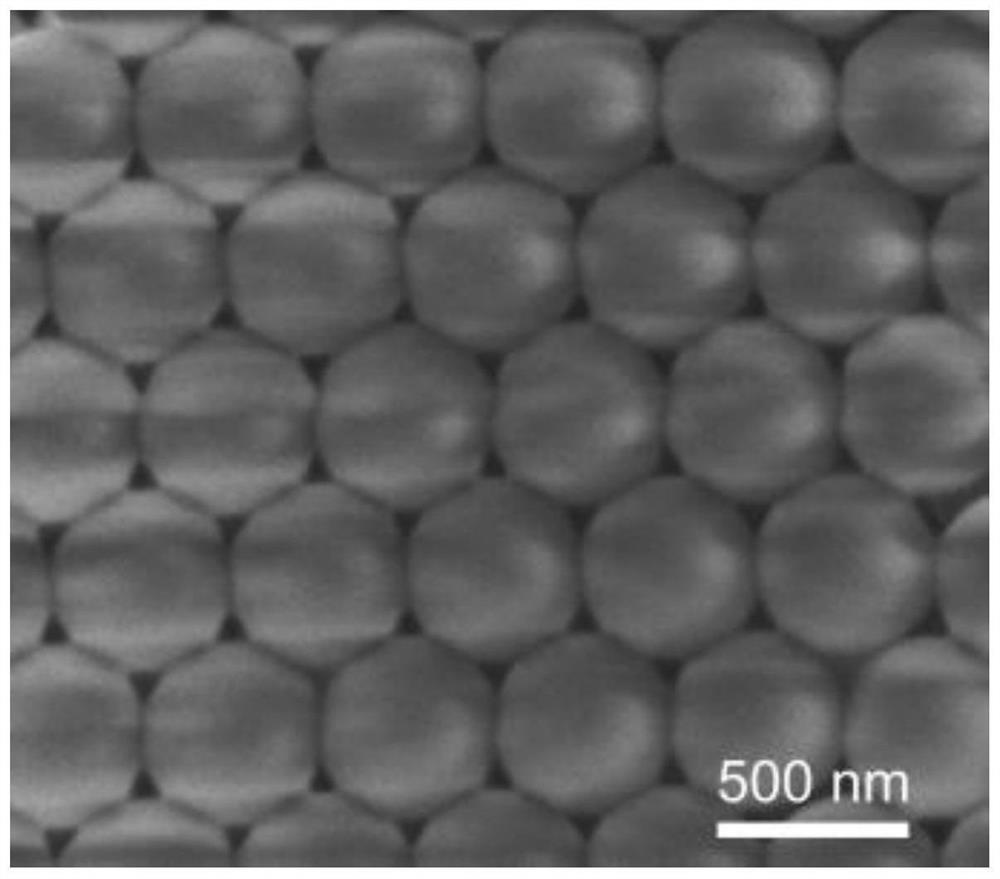

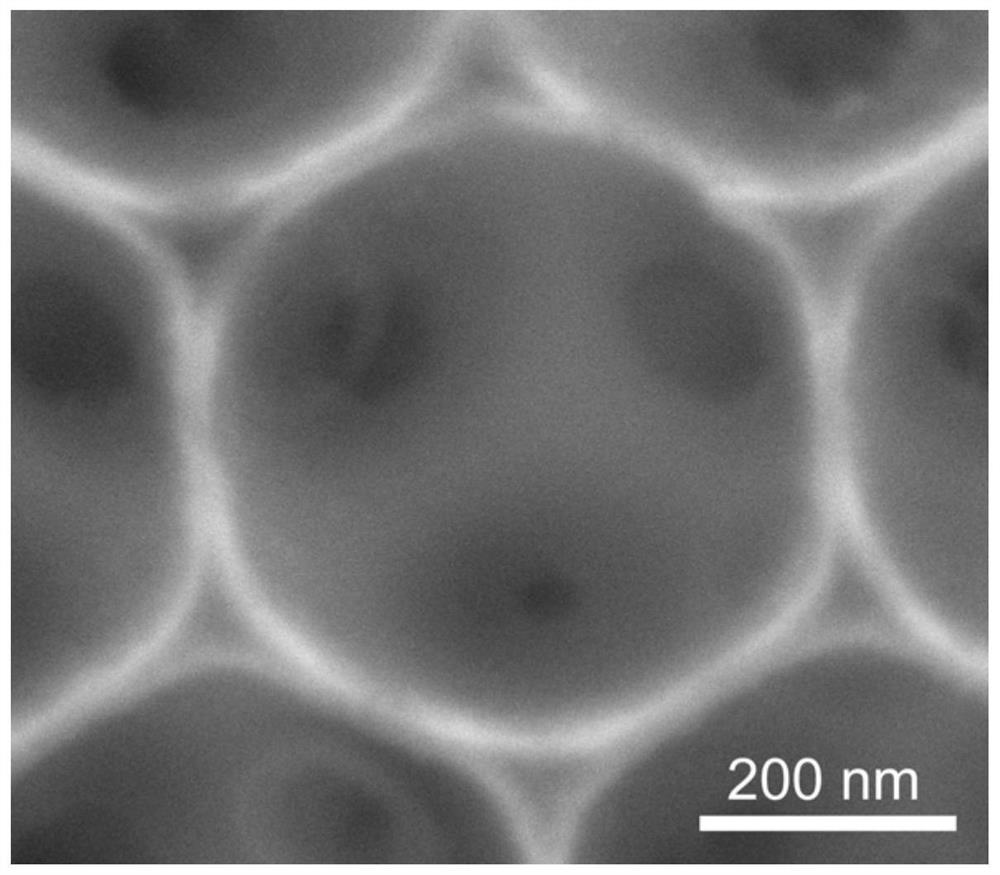

[0045] B. Take 2 milliliters of commercial 2.5% polystyrene solution with a diameter of 500 nanometers, place it in 30 milliliters of water, ultrasonicate for 30 minutes, add the resulting polystyrene solution onto the tungsten substrate, and dry it at 50°C for 12 Hours, a polystyrene template with a three-dimensional ordered structure was obtained.

[0046] C. Take 1 ml of the conductive hydrogel polyaniline sol obtained in step A and add it dropwise to the polystyrene template with three...

Embodiment 2

[0049] A method for preparing a three-dimensional ordered porous structure hydrogel-loaded sulfur particle composite material, comprising the following steps:

[0050]A. Dissolve 1 milliliter of aniline and 2 milliliters of phytic acid in 10 milliliters of water, stir in an ice-water bath for 10 minutes, add 20 milliliters of ammonium persulfate solution in which 7 grams of ammonium persulfate is dissolved, and continue stirring at 1°C for 10 minutes in an ice-water bath Minutes to obtain a uniformly mixed conductive hydrogel polyaniline sol.

[0051] B. Take 1 milliliter of a commercial 2.5% polystyrene solution with a diameter of 500 nanometers, place it in 30 milliliters of water, ultrasonicate for 30 minutes, add the polystyrene solution dropwise on the tungsten substrate, and dry it at a constant temperature at 60°C for 10 hours. A polystyrene template with a three-dimensional ordered structure was obtained.

[0052] C. Take 1 ml of the conductive hydrogel polyaniline so...

Embodiment 3

[0055] A method for preparing a three-dimensional ordered porous structure hydrogel-loaded sulfur particle composite material, comprising the following steps:

[0056] A. Dissolve 2 ml of aniline and 4.3 ml of phytic acid in 10 ml of water, stir in an ice-water bath for 10 minutes, add 30 ml of ammonium persulfate solution with 10 grams of ammonium persulfate dissolved in it, and continue stirring for 10 minutes in an ice-water bath at 3°C , to obtain a uniformly mixed conductive hydrogel polyaniline sol.

[0057] B. Take 2 milliliters of commercial 2.5% polystyrene solution with a diameter of 500 nanometers, place it in 30 milliliters of water, ultrasonicate for 30 minutes, add the polystyrene solution to the tungsten substrate, and dry it at 65°C for 10 minutes Hours, a polystyrene template with a three-dimensional ordered structure was obtained.

[0058] C. Take 1 ml of the conductive hydrogel polyaniline sol obtained in step A and add it dropwise to the polystyrene templa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com