Light splitter light splitting-based SP simulation lighting super-resolution photoetching lens and device

A technology for exciting illumination and spectroscope, applied in the field of super-resolution lithography, can solve the problem that the lithography device cannot meet the needs of super-resolution lithography, and achieve the effect of convenient exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose, technical solution and advantages of the device of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

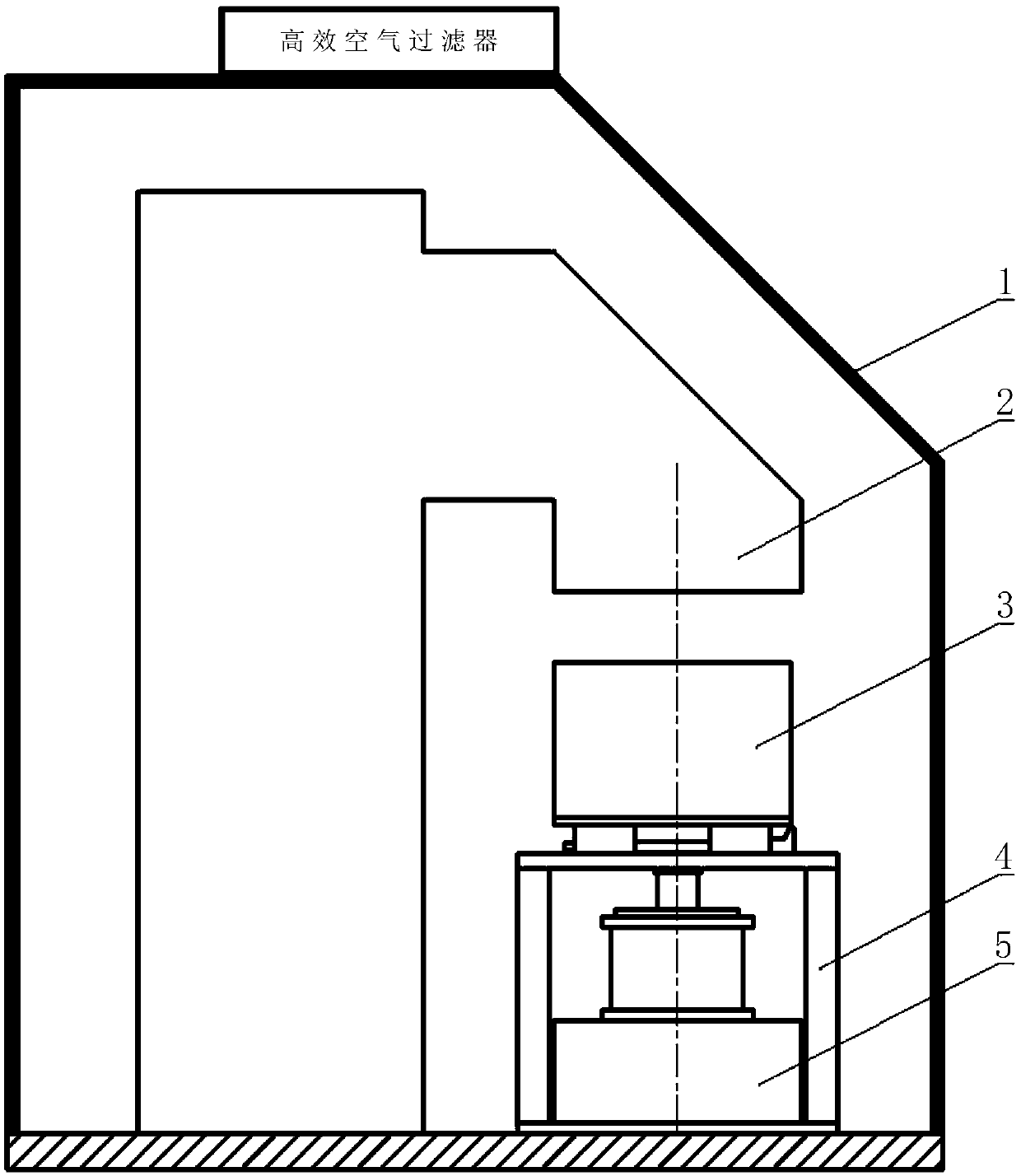

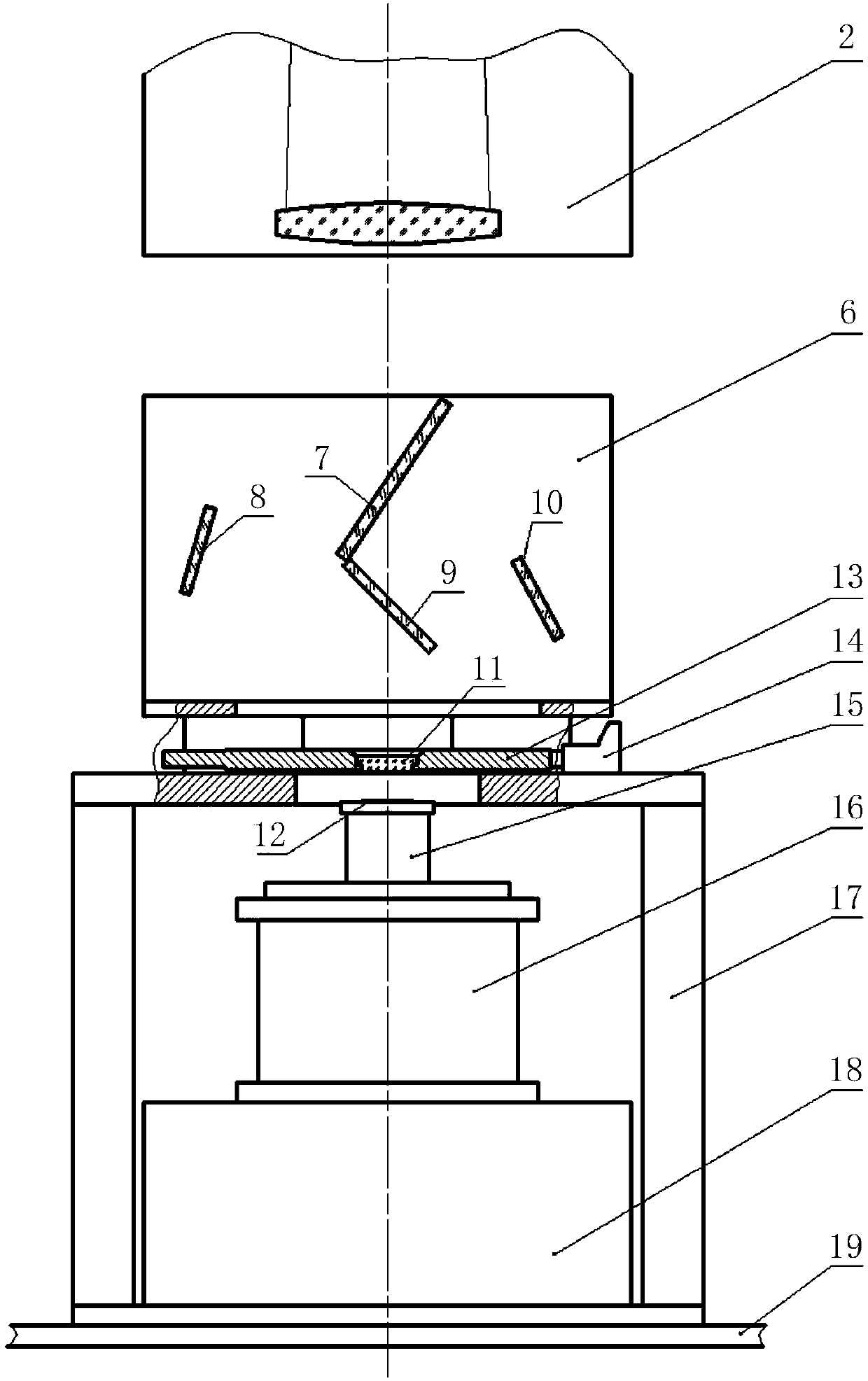

[0050] refer to figure 1 , a SP excitation illumination super-resolution lithography device based on beam splitting, the device includes an air purification system 1 for protecting the lithography device, a light source 2 for generating i-line ultraviolet exposure light beams, and a spectrophotometer for excitation illumination A mirror beam splitting system 3, a mask carrying module 4 for carrying a surface plasmon imaging device, and a workbench 5 for carrying a substrate. Among them, the air purification system 1 can ensure a good lithography environment on the one hand, and on the other hand, it is beneficial to the maintenance of the lithography device; the light source 2 provides the i-line ultraviolet exposure beam for the entire lithography ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com