A sealing test device and a sealing test system for a turntable bearing

A technology for sealing testing and slewing bearings, which is applied in the direction of using liquid/vacuum for liquid tightness measurement and measuring the acceleration and deceleration rate of fluids. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

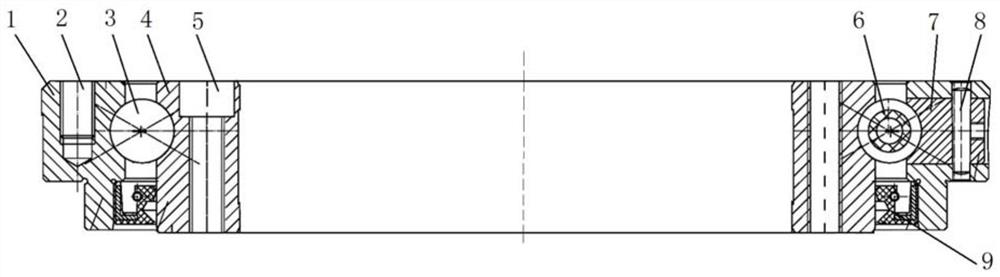

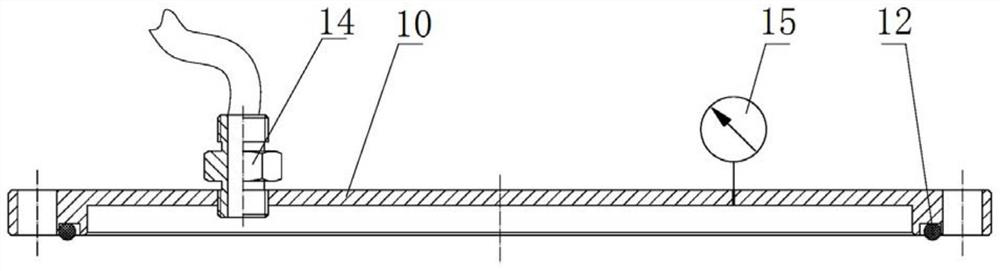

[0047] Embodiment 1 of the slewing bearing sealing test device of the present invention, as figure 2 As shown, the slewing bearing sealing test device includes an outer ring cover 10 , an inner ring cover 11 , an inflation joint 14 and a pressure detection device 15 .

[0048] In this embodiment, the bearing to be tested is a slew bearing with a ball hole provided on the outer ring. The outer ring cover 10 is sealed and connected to the end surface of the bearing outer ring 1 facing away from the sealing ring 9, and the inner ring cover 11 is sealed. Connected to the end of the bearing inner ring 4 close to the sealing ring 9, the outer ring cover 10, the outer ring 1, the sealing ring 9, the inner ring 4 and the inner ring cover 11 are sequentially connected to form a closed inner cavity, and the outer ring 1 and The space between the slideways of the inner ring 4 for accommodating rolling elements, spacers and lubricating grease is a part of the closed cavity.

[0049] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com