Sliding bearing with aligning function

A sliding bearing and self-aligning technology, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of poor adaptability to roller shaft load changes and low service life of sliding bearings, so as to improve the working condition of swing fit and improve Effect of service life and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

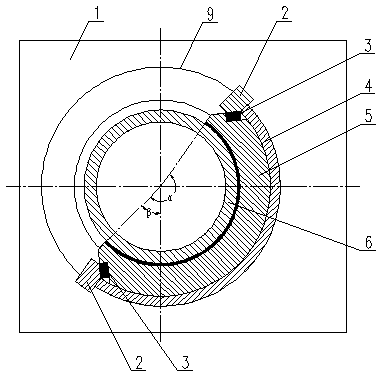

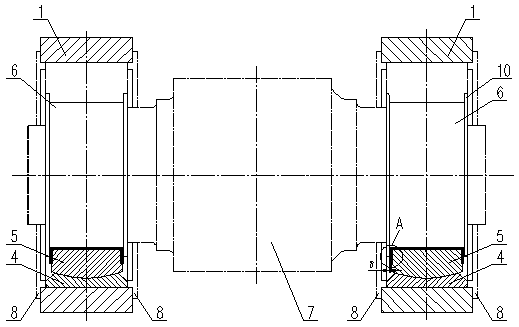

[0052] like Figure 1-4 As shown, a CLM260160 adjustable center sliding bearing for the rotating shaft of a high-pressure roller mill. The rotating shaft 7 includes a driving end and a floating end. The journal speed of the rotating shaft 7 is ≤1.5m / s, and the journal pressure is ≤25MPa. The central sliding bearing includes a bearing seat 1, which is used to fit the sleeve 6 at the journal of the rotating shaft 7. The outer surface of the sleeve 6 is placed in the inner surface of the spherical pad 5 to form a circumferential sliding friction pair. The spherical pad The outer surface of 5 protrudes outward to form an outer spherical surface, forming the outer spherical surface of spherical tile 5. The arc surface forms the outer circular surface of the spherical seat 4, the outer spherical surface of the spherical shoe 5 is in contact with the inner spherical surface of the spherical seat 4 to form a rolling friction pair relationship, and the spherical seat 4 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com