A PC box girder web reinforcement structure and method with built-in oblique mesh

A technology for strengthening structures and webs, which is applied in the field of structural engineering and bridge structures, can solve problems such as web cracking, achieve the effects of preventing buckling and fracture, being easy to implement, and avoiding secondary construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

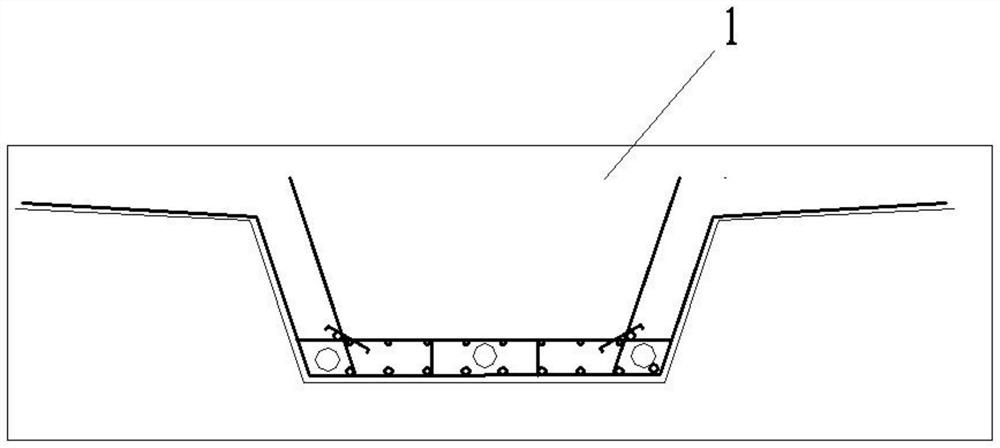

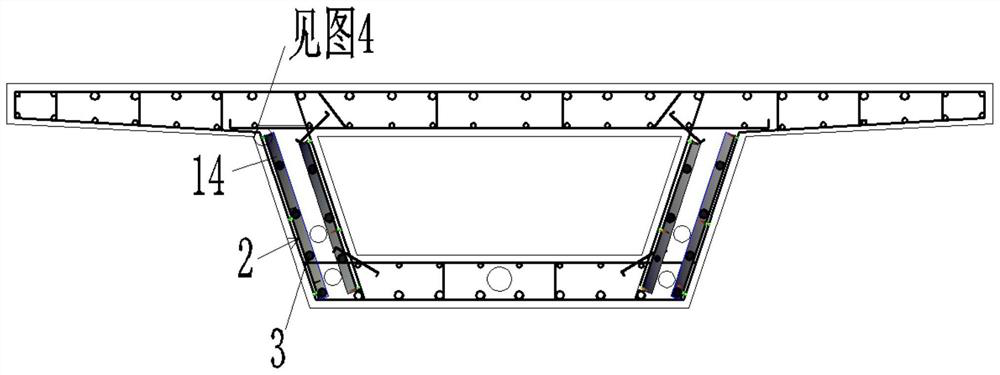

[0037] For ease of description, the relative positions of the components described below are only based on the actual situation of the structure, which is only an example of the implementation of the present invention, and the present invention is not limited by the following. Any process equivalent conversion or direct application of the content of the present invention is within the scope of patent protection of the present invention.

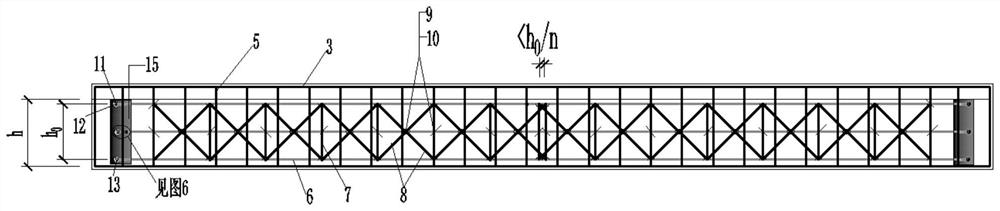

[0038] 1. Prepare steel strand mesh (2) according to the size of the semi-finished steel cage (1)

[0039] The steel strands used in the steel strand mesh (2) are all made of scored steel strands with a number of steel wires ≥ 3, so that they have high tensile strength and certain bending resistance, so as to increase the wrapping with concrete After the tension is completed, the mesh is prefabricated. take h 0 less than the web-bottom vertical height of the semi-finished reinforcement cage (1), the h 0 Divided into suitable equal parts n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com