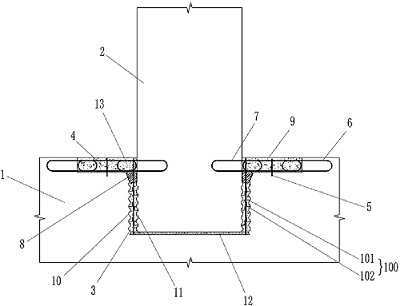

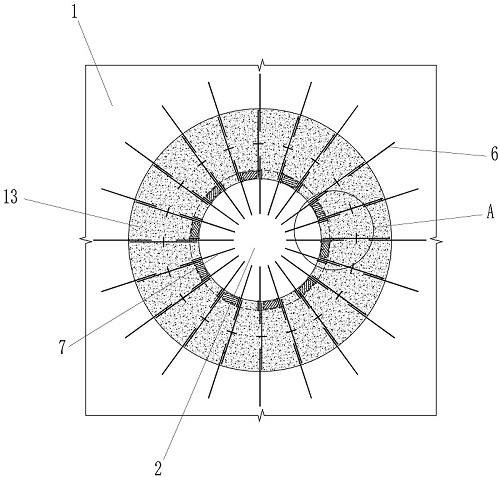

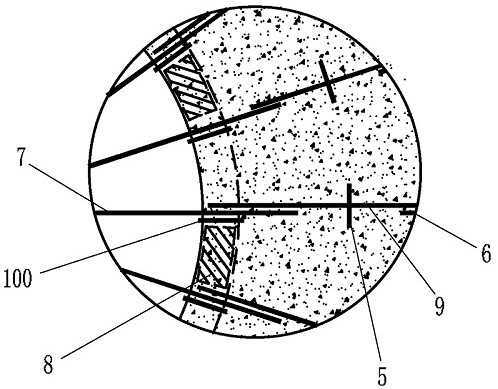

Socket and spigot joint type connecting structure based on T-shaped groove and construction method thereof

A technology for connecting structures and construction methods, applied to bridge parts, erecting/assembling bridges, bridges, etc., can solve the problems of poor durability and seismic performance, and achieve the effect of reducing construction costs and reducing the depth of socket sockets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the above objects, features, and advantages of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Many specific details are set forth in the following description to fully understand the present invention. However, the present invention can be implemented in many other fails there are many otherwise described herein, and those skilled in the art can be similarly improved without departing from the connotation of the present invention, and thus the present invention is not limited by the specific embodiments disclosed below.

[0045] In the description of the present invention, it is to be noted that the term "connected", "connection",, unless otherwise express, "Connect", should be a generalized understanding, for example, may be a fixed connection, or a detachable connection, or integral Connect; may be mechanical connections, or electrical connection, may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com