Single particle size ultra-thin anti-slip wearing layer used for road preventive maintenance and construction process thereof

A preventive maintenance and construction technology, applied in the direction of roads, roads, condensed pavement paved on site, etc., can solve the problems of reducing the comfort of drivers and passengers, increasing the emission of harmful gases, and increasing the noise of vehicles. , to achieve significant noise reduction, prolong service life, and improve anti-skid performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a kind of preparation method of modified emulsified asphalt, comprising the following steps:

[0040] (1) Mix asphalt, SBS, epoxy resin and compatibilizer, heat to 120-180°C, shear and disperse, stir for health;

[0041] (2) Add emulsifier, stabilizer and solvent again, and heat and stir;

[0042] (3) Then add modified filler, continue heating and stirring to obtain modified emulsified asphalt.

[0043] The present invention also provides a construction process for the above-mentioned single particle size ultra-thin anti-skid wear layer for preventive maintenance of roads, which includes the following steps:

[0044] 1) Preparation before construction, including raw material preparation and mechanical preparation; said raw material preparation includes preparing asphalt mixture;

[0045] 2) Underlayer preparation: clean the original asphalt pavement before construction, and treat and repair existing diseases, and then use high-press...

Embodiment 1

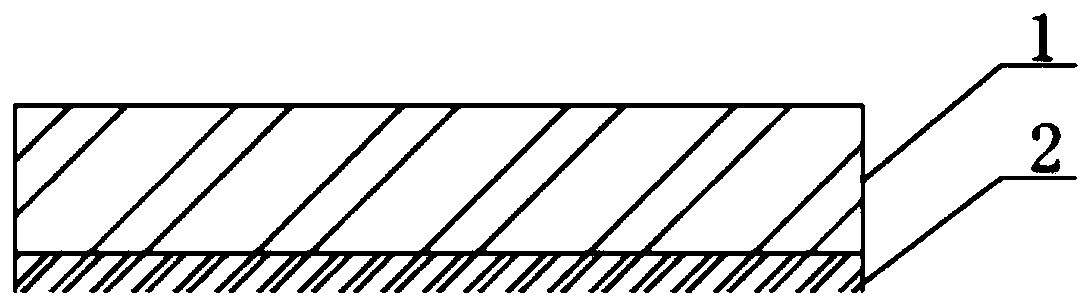

[0051] The ultra-thin anti-skid wear layer with a single particle size is formed by paving and rolling the asphalt mixture with a single particle size on the road surface through a paver. The asphalt mixture consists of 0.5-10 parts by weight of composite filler, 9-15 parts by weight of The modified emulsified asphalt and 80-110 parts by weight of basalt aggregate are stirred at room temperature. Wherein, the composite filler includes fly ash, polyamide fiber, carbon fiber, boron nitride fiber, aluminum hydroxide powder and zirconia powder.

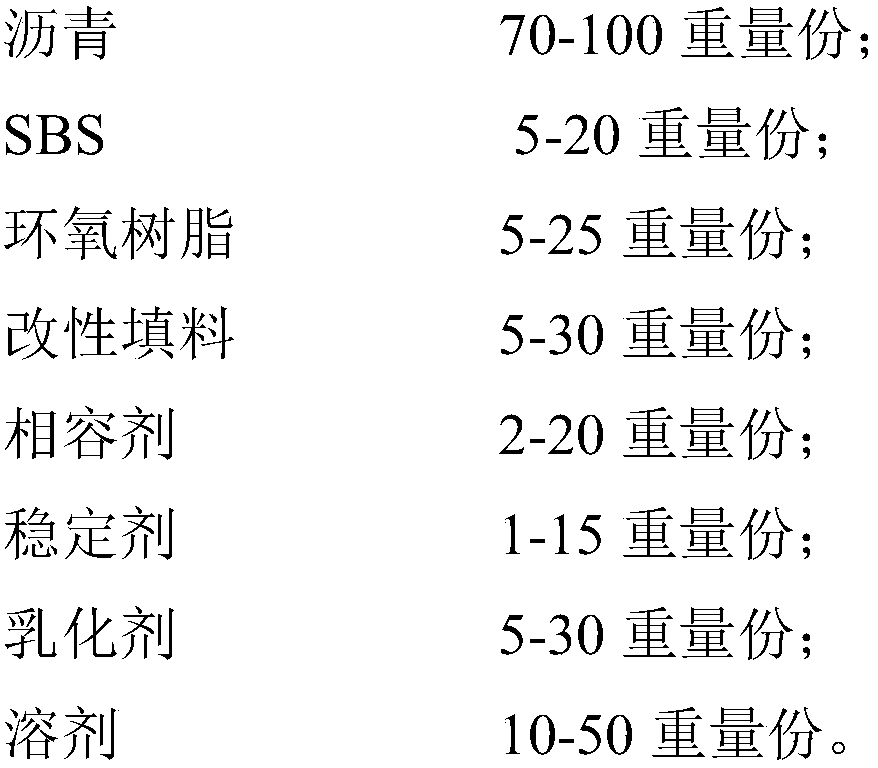

[0052] The modified emulsified asphalt comprises the following raw materials in parts by weight:

[0053]

[0054] Wherein, the modified filler includes boron nitride fiber, nano-zinc oxide, nano-silicon dioxide and nano-alumina.

Embodiment 2

[0056] The ultra-thin anti-skid wear layer with a single particle size is formed by paving and rolling the asphalt mixture with a single particle size on the road surface through a paver. The asphalt mixture consists of 0.5-10 parts by weight of composite filler, 9-15 parts by weight of Modified emulsified asphalt and 100 parts by weight of basalt aggregate are stirred at room temperature. Wherein, the composite filler includes fly ash, polyamide fiber, carbon fiber, boron nitride fiber, aluminum hydroxide powder and zirconia powder.

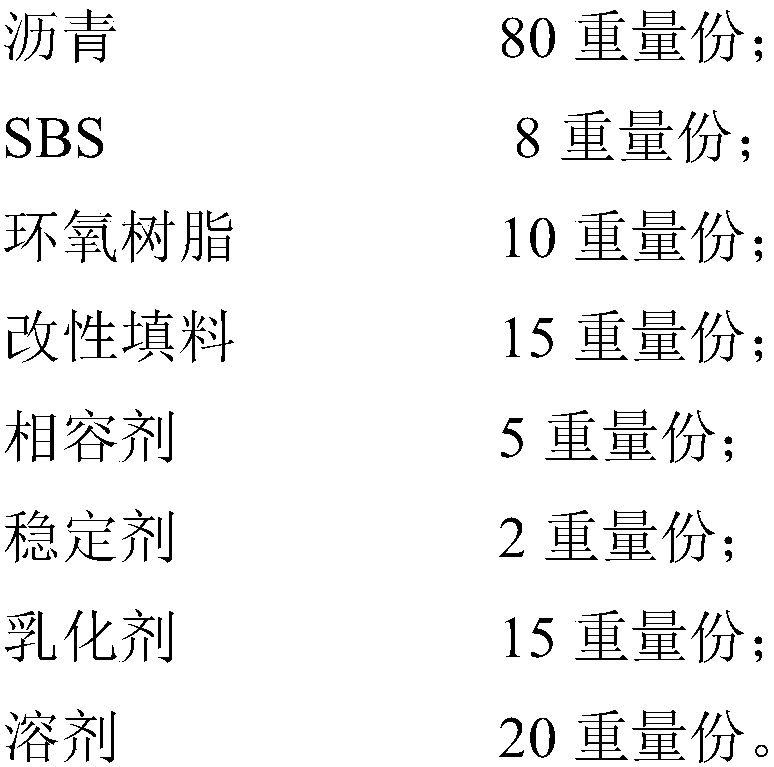

[0057] The modified emulsified asphalt comprises the following raw materials in parts by weight:

[0058]

[0059] Wherein, the modified filler includes boron nitride fiber, nano-zinc oxide, nano-silicon dioxide and nano-alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com