Anti-bacterial high polymer material and preparation method and application thereof

A polymer material and molecular structure technology, applied in the field of synthesis of functional polymer materials, to achieve the effect of good inhibition of growth, good inhibition of adhesion, and great development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

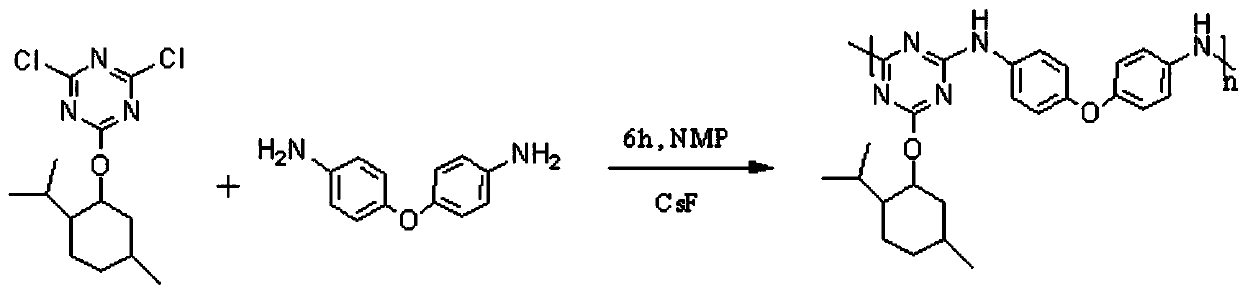

[0053] In this embodiment, the preparation flow chart of the antibacterial polymer material with molecular structure as shown in formula (I) is as follows figure 1 shown.

[0054] Weigh 1mmol of cyanuric chloride-derived polymerizable monomer compound and 1mmol of 4,4'-diaminodiphenyl ether in a reaction flask, add 2ml of nitrogen-methylpyrrolidone (NMP) to provide a solvent environment, and then add 2.2mmol Cesium fluoride (CsF) was used as a catalyst, reacted at 120°C for 6 hours, and the product was precipitated and purified 3 times in a large amount of methanol to obtain a polymer derived from cyanuric chloride [(that is, the molecular structure is as shown in formula (I) Antibacterial macromolecular material)] pure product, its productive rate is 60%, and molecular weight is 10000. The polymerization method has the advantages of simple operation and convenient purification.

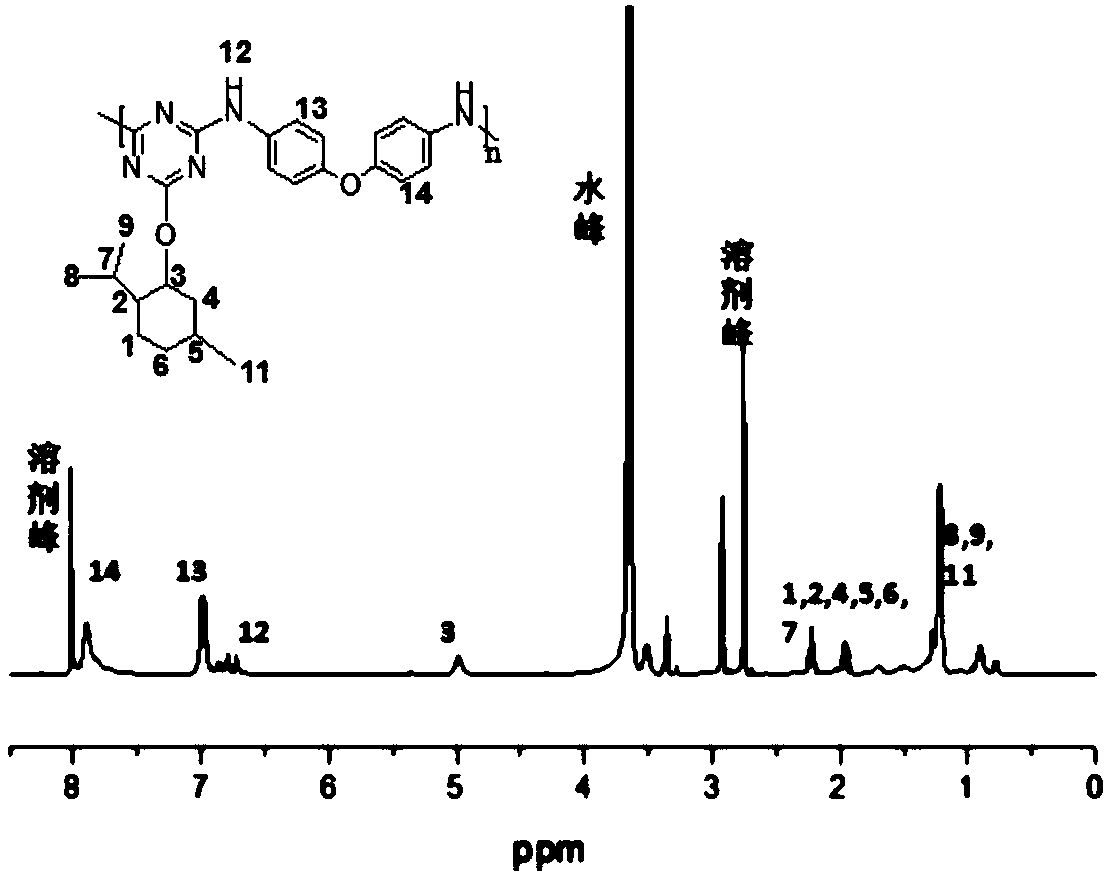

[0055] Adopt nuclear magnetic resonance instrument (Bruker AVANCE 300MHz type nuclear magnetic ...

Embodiment 2

[0057] Weigh 1mmol of cyanuric chloride-derived polymerizable monomer compound and 1mmol of 4,4'-diaminodiphenyl ether in a reaction flask, add 2ml of nitrogen-methylpyrrolidone (NMP) to provide a solvent environment, and then add 2.2mmol Cesium fluoride (CsF) was used as a catalyst, reacted at 150°C for 6 hours, and the product was precipitated and purified 3 times in a large amount of methanol to obtain a polymer derived from cyanuric chloride [(that is, the molecular structure is as shown in formula (I) Antibacterial macromolecular material)] pure product, its productive rate is 50%, molecular weight is 13500, and this polymerization method has the advantages of simple operation and easy purification.

Embodiment 3

[0059] Weigh 1mmol of cyanuric chloride-derived polymerizable monomer compound and 1mmol of 4,4'-diaminodiphenyl ether in a reaction flask, add 2ml of nitrogen-methylpyrrolidone (NMP) to provide a solvent environment, and then add 2.2mmol K 2 CO 3 As a catalyst, react at 100°C for 6h. Removal of K by physical adsorption method 2 CO 3 . The product is precipitated and purified 3 times in a large amount of methanol, and the polymer derived from cyanuric chloride [(i.e. molecular structure such as the antibacterial macromolecular material shown in formula (I))] pure product, its productive rate 50%, molecular weight is 9800, the polymerization method has the advantages of simple operation and easy purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com