Preparation method of photoresponsive cinnamic acid derivative-grafted nanocellulose

A technology of cinnamic acid derivatives and nanocellulose is applied in the field of preparation of light-responsive cinnamic acid derivatives grafted nanocellulose, which can solve the problems of limiting the application range of nanocellulose and single surface functional group, and achieve good light-responsive performance. , high specific surface area, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

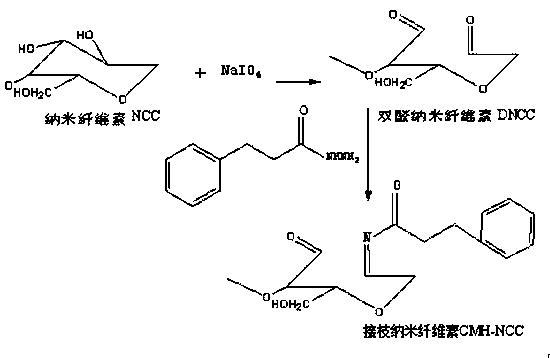

Method used

Image

Examples

Embodiment 1

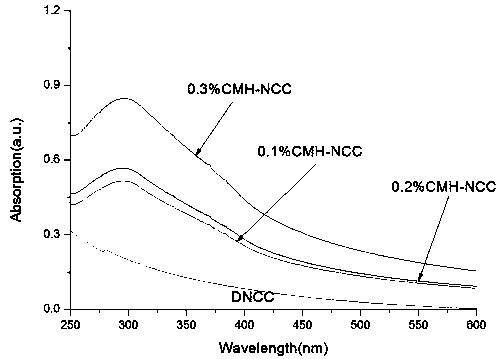

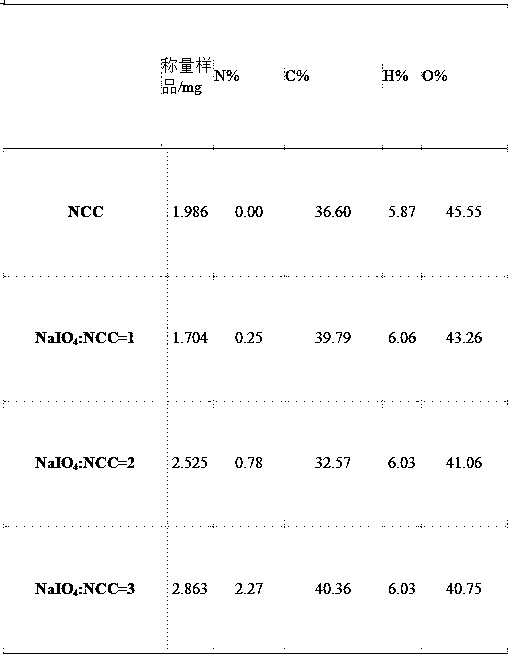

[0022] (1) According to the material-to-liquid ratio of 1:70, the microcrystalline cellulose raw material was added to 70wt% sulfuric acid solution, and nanocellulose was prepared by ultrasonication at 65°C for 4 hours, and the nanocellulose solution was obtained by dialysis.

[0023] (2) Take 2g of NaIO 4 Dissolve in deionized water, add 0.1mol / L sulfuric acid to adjust pH=3.5. Add it to a nanocellulose solution with a certain solid content of 2g, add deionized water to make a cellulose solution with a mass concentration of 2%, and place it in a dark place at 40°C for 6 hours to react in the dark and avoid light to prepare dialdehyde nanofibers white.

[0024] (3) Dialyze the prepared dialdehyde nanocellulose for 2 days to remove sodium periodate, take a certain amount of solution and add DMF (N,N-dimethylformamide) centrifugation for 3-5 times to replace deionized water, DMF was then added to form a dialdehyde cellulose DMF solution with a mass concentration of 2%.

[002...

Embodiment 2

[0028] (1) According to the material-to-liquid ratio of 1:70, the recycled old paper fiber raw materials were added to 65wt% sulfuric acid solution, and nanocellulose was prepared by ultrasonication at 65°C for 4 hours, and the nanocellulose solution was obtained by dialysis.

[0029] (2) Take 4g of NaIO 4 Dissolve in deionized water, add 0.1mol / L sulfuric acid to adjust pH=3.5. Add it into a nanocellulose solution with a certain solid content of 2g, add deionized water to make a cellulose solution with a mass concentration of 2%, and place it in a dark place at 40°C for 6 hours while stirring and avoiding light.

[0030] (3) Dialyze the prepared dialdehyde nanocellulose for 2 days to remove sodium periodate, take a certain amount of solution and add DMF (N,N-dimethylformamide) centrifugation for 3-5 times to replace deionized water, DMF was then added to form a dialdehyde cellulose DMF solution with a mass concentration of 2%.

[0031] (4) Add 1 g of cinnamoyl chloride into...

Embodiment 3

[0034] (1) According to the material-to-liquid ratio of 1:70, the straw pulp fiber raw material was added to 55wt% sulfuric acid solution, and nanocellulose was prepared by ultrasonication at 65°C for 4 hours, and the nanocellulose solution was obtained by dialysis and rotary steaming.

[0035] (2) Take 6g of NaIO 4 Dissolve in deionized water, add 0.1mol / L sulfuric acid to adjust pH=3.5. Add it into a nanocellulose solution with a certain solid content of 2g, add deionized water to make a cellulose solution with a mass concentration of 2%, and place it in a dark place at 40°C for 6 hours while stirring and avoiding light.

[0036] (3) Dialyze the prepared dialdehyde nanocellulose for 2 days to remove sodium periodate, take a certain amount of solution and add DMF (N,N-dimethylformamide) to centrifuge for 3-5 times to replace deionized water. DMF was then added to form a dialdehyde cellulose DMF solution with a mass concentration of 2%.

[0037] (4) Add 1 g of cinnamoyl chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com