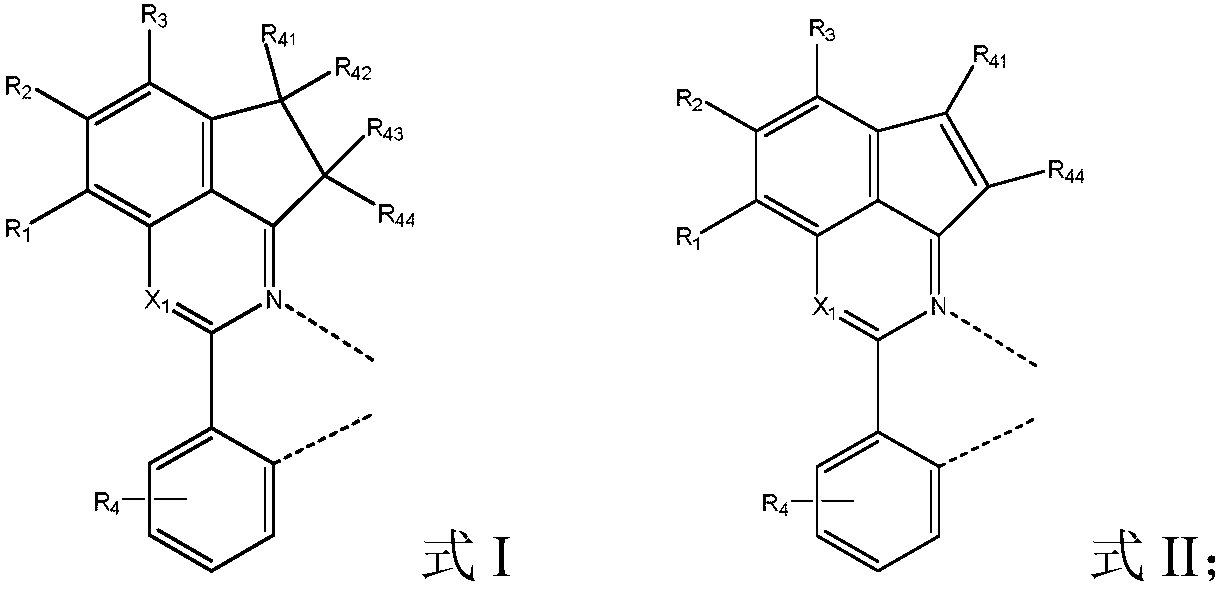

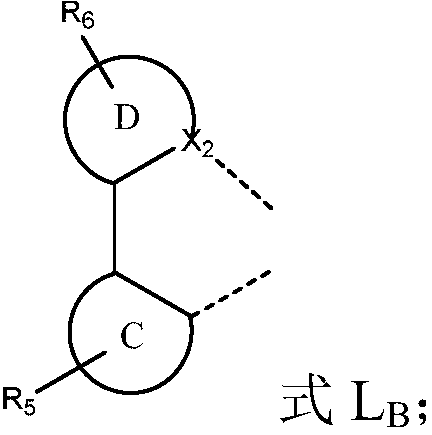

Metal complex, organic electroluminescent material, organic electroluminescent device

A technology of metal complexes and metals, applied in luminescent materials, electrical solid devices, electrical components, etc., can solve the problems of reducing the quantum yield of the red light system, intensifying the quenching of phosphors, and low luminous quantum efficiency, achieving easy sublimation Purification, good thermal stability, and high external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0205] The preparation of the ligand of structure shown in formula LA314:

[0206] The preparation method of ligand LA314 comprises the following steps:

[0207] The first step: preparation of compound Int-1

[0208]

[0209] Disperse 5.1g (30.5mmol) of chloral hydrate in 100mL of water, add 35.1g (247.1mmol) of anhydrous sodium sulfate, heat the oil bath to 35°C, stir to dissolve, and add 4.7g (27.7mmol) of 1-aminoindene at one time Fill the mixed solution of hydrochloride, 6.1g (88.1mmol) of hydroxylamine hydrochloride and 30mL of water, heat up to 90°C, stir and react for 8 hours, cool to room temperature, filter, wash the filter cake with water, and dry to obtain 4.7g of yellow solid .

[0210] Add the yellow solid obtained above to 50 mL of 60°C 86% sulfuric acid, control the temperature at 60-65°C, stir for 30 minutes, raise the temperature to 80°C, stir for 30 minutes, cool to room temperature, pour the reaction solution into 500 mL of ice water was filtered, the ...

Embodiment 2

[0221] For the preparation of compounds LA1-LA313, LA315-LA563, LA787-LA1912, refer to the preparation method of Example 1, and replace the 1-amino indane hydrochloride with different substituents in the first step in Example 1 Indane hydrochloride, replace 3,5-dimethylphenylboronic acid in the fourth step in Example 1 with phenylboronic acid with different substituents to prepare LA1~LA313, LA315~LA563 and LA787~ LA1912.

Embodiment 3

[0223] The preparation of the ligand of structure shown in formula LA697:

[0224] Put 5.0g (19.3mmol) LA314 into the single-port reaction flask, add 20mL deuterated ethanol, then add 5g (73.5mmol) sodium ethoxide, heat up and reflux for 12 hours, cool to room temperature, concentrate to dryness under reduced pressure, and separate with a silica gel column After purification, 4.8 g of the ligand compound represented by the formula LA697 was obtained as a white solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com