Cooling body with regulator

A regulator and cooling body technology, applied in the direction of glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting the moving distance of movable parts, affecting the service life of the bushing plate, and large shaking space, so as to improve product quality and production stability. The effect of improving the distance of movement and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

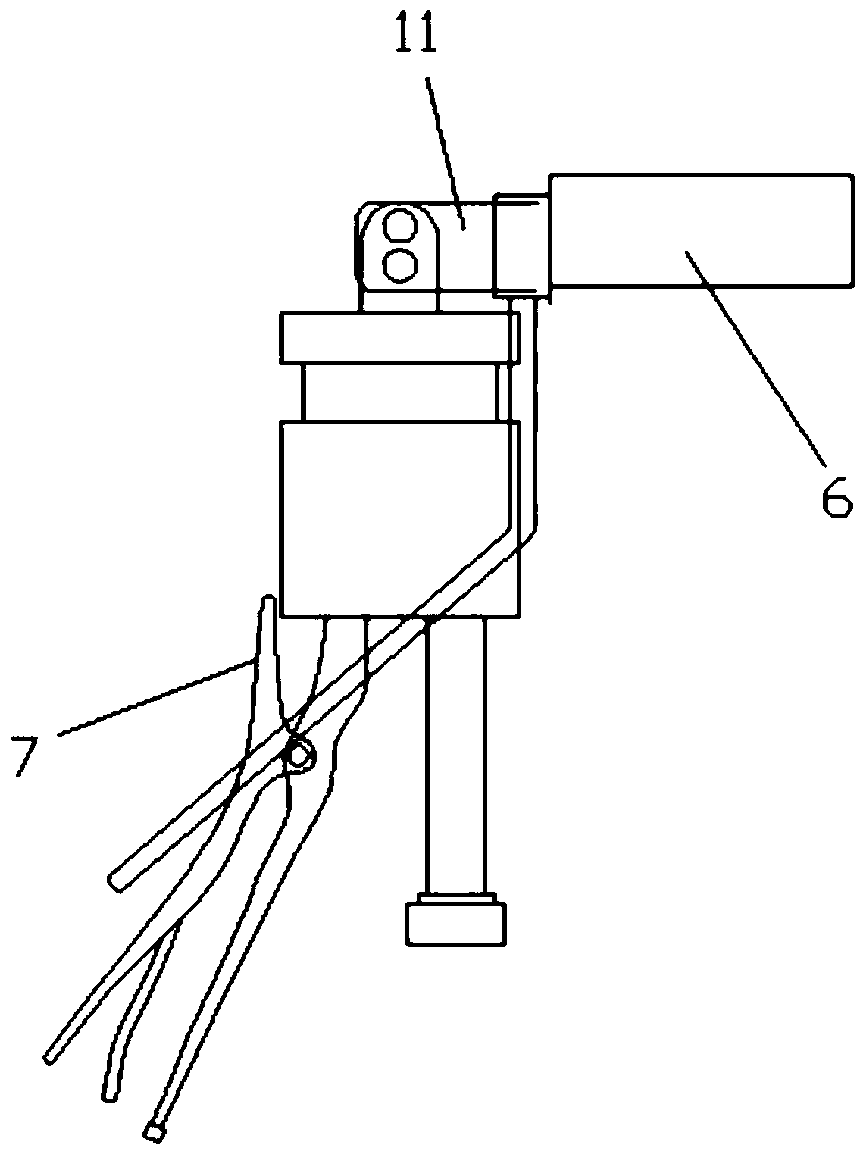

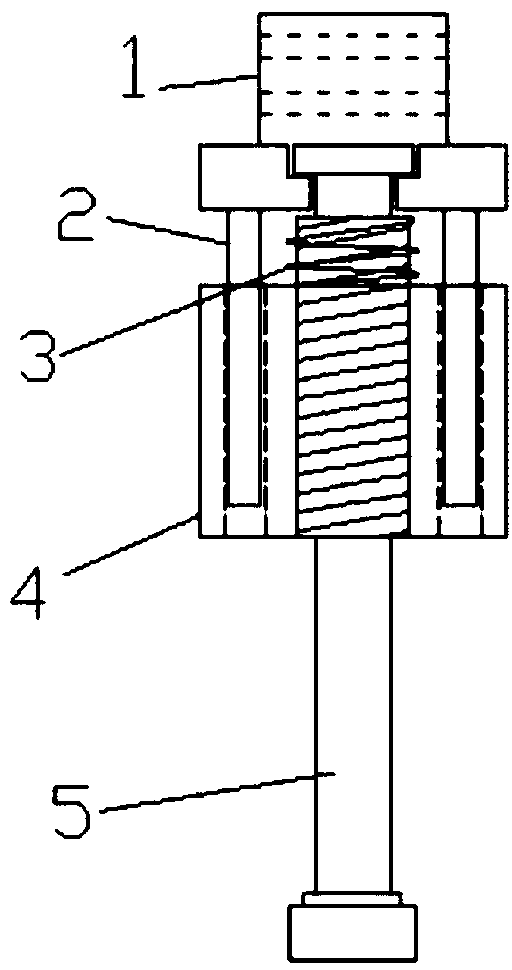

[0047] Take the four-point pull cooler as an example, such as Figure 4 shown.

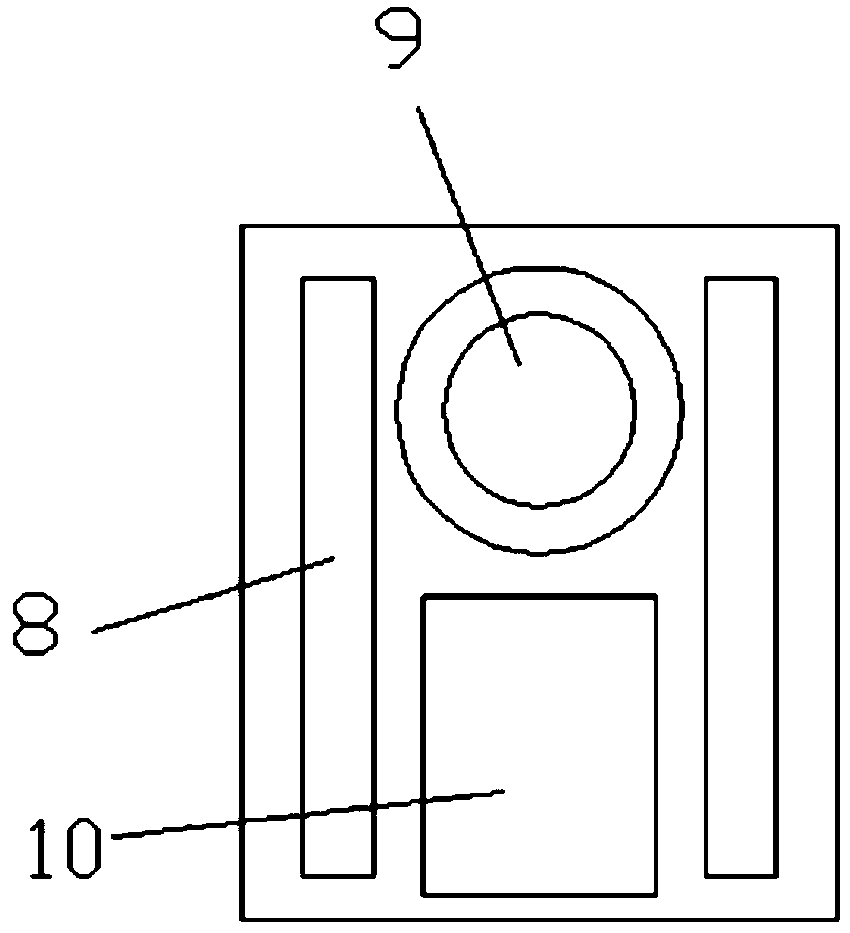

[0048] There are 13 cooling fins drawn in four quarters, and the specifications are length*width*height=55*20*2, and they are uniformly fixed on one side of the bar block on the cooler, and the water inlet and outlet pipes are set at both ends of the bar block. There is a through hole in the middle of the strip block, which communicates with the water inlet pipe and the water outlet pipe, allowing cooling water to pass through. The cooling fins 6 are arranged in parallel, and two connecting pieces 11 are fixed below the strip block, and two bolts are arranged on the connecting piece 11 hole.

Embodiment 2

[0050] Take the eight-point pull cooler as an example, such as Figure 5 shown.

[0051] There are 12 pieces of cooling fins in the Bafen pull, and the specifications are length*width*height=50*20*1.3, and they are evenly fixed on one side of the bar block on the cooler, and the water inlet and outlet pipes are set at both ends of the bar block. There is a through hole in the middle of the strip block, which communicates with the water inlet pipe and the water outlet pipe, allowing cooling water to pass through. The cooling fins 6 are arranged in parallel, and two connecting pieces 11 are fixed below the strip block, and two bolts are arranged on the connecting piece 11 hole.

Embodiment 3

[0053] Take Shifenla cooler as an example, such as Figure 6 shown.

[0054] There are 6 cooling fins that are very stretched, and the specifications are length*width*height=85*20*1.0, and they are evenly fixed on one side of the bar block on the cooler. There is a through hole in the middle of the shaped block, which communicates with the water inlet pipe and the water outlet pipe, so that cooling water can pass through. The cooling fins 6 are arranged in parallel, and two connecting pieces 11 are fixed under the strip block, and two bolt holes are opened on the connecting piece 11. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com