Aerosol can automatic production line collection device

An automatic production line and collection device technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of increasing product scrap rate, deformation and damage of aerosol cans, etc., to avoid deformation damage, reduce impact force, and ensure The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

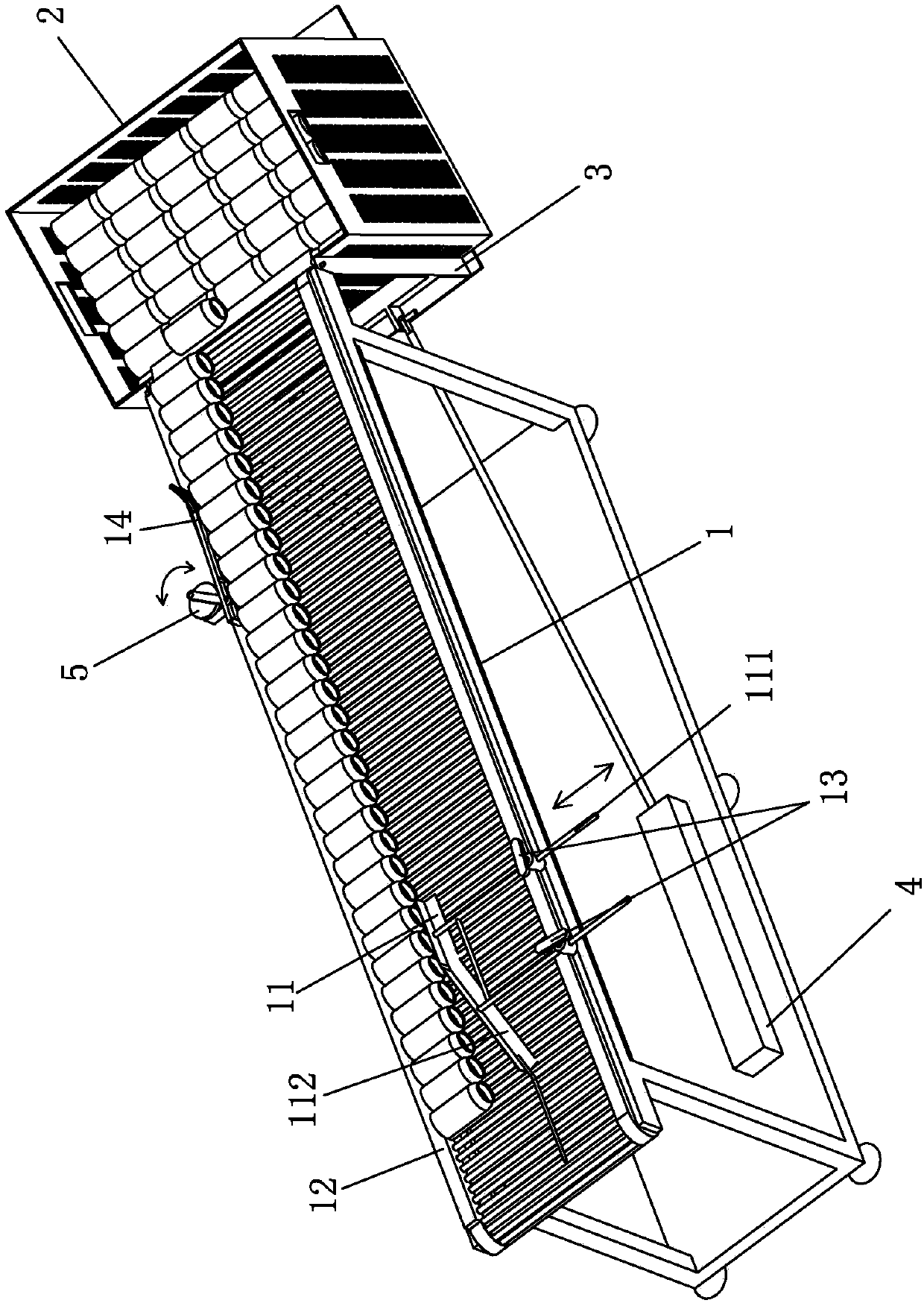

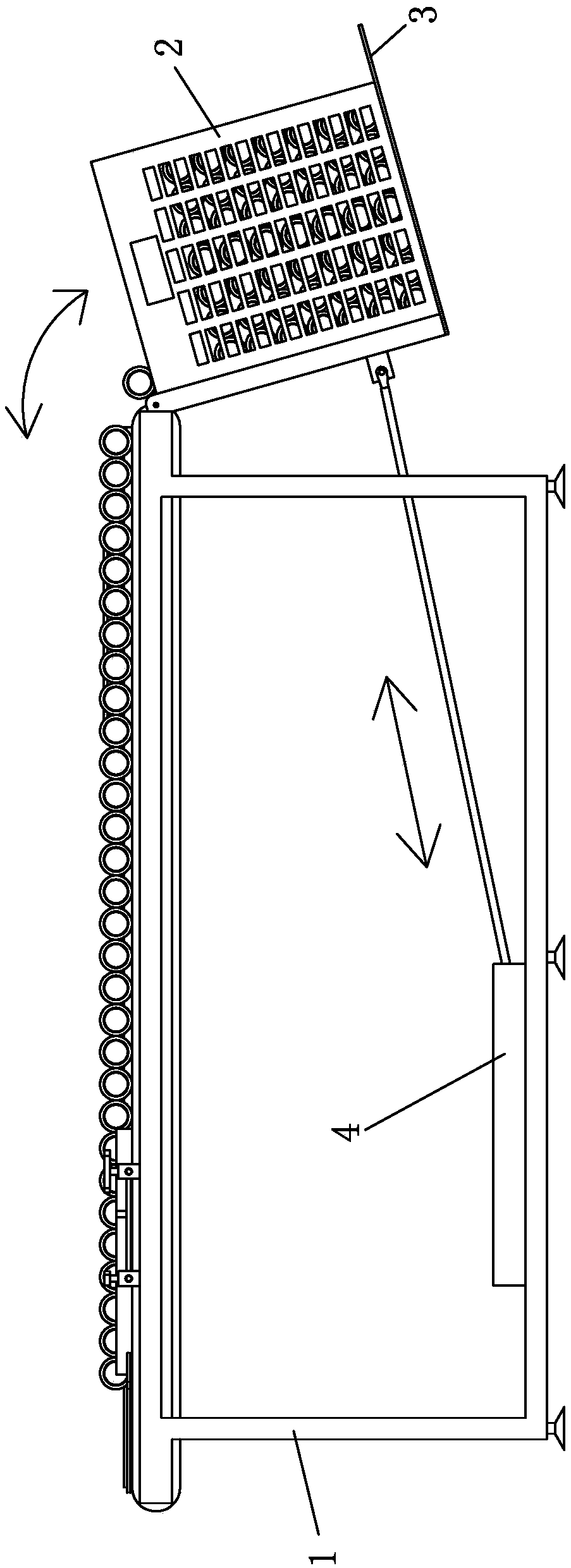

[0023] see figure 1 , figure 2 , the automatic production line collection device for aerosol cans includes a conveying bracket 1, the discharge end of the conveying bracket 1 is provided with a loading bracket 3 for placing a storage tank basket 2, one end of the loading bracket 3 is hinged with the delivery bracket 1, and the other One end is connected to the deceleration pusher 4, and the cargo support 3 swings up and down around its hinged end under the action of the deceleration pusher 4, and the deceleration pusher 4 plays a role of pushing and supporting the cargo support 3 at the same time, and the load support 3 Under the action of the deceleration pusher 4, the inclination angle between the storage tank basket 2 and the horizontal plane is reduced, thereby reducing the impact force of the aerosol tank falling into the storage tank basket 2, avoiding deformation and damage of the aerosol tank, and ensuring The production quality of the product.

[0024] Further, the...

no. 2 example

[0034] The difference between this embodiment and the first embodiment is that the detection device of the aerosol can automatic production line collection device is an electronic weighing device, and the electronic weighing device is arranged on the bottom position of the loading bracket 3 corresponding to the storage tank basket 2 .

[0035] The rest of the undescribed parts are the same as those of the first embodiment and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com