Cargo sorting system and a cargo sorting method

A technology of goods and handling systems, applied in the field of warehousing and logistics, to achieve the effect of improving efficiency and accuracy, improving management efficiency and management accuracy, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

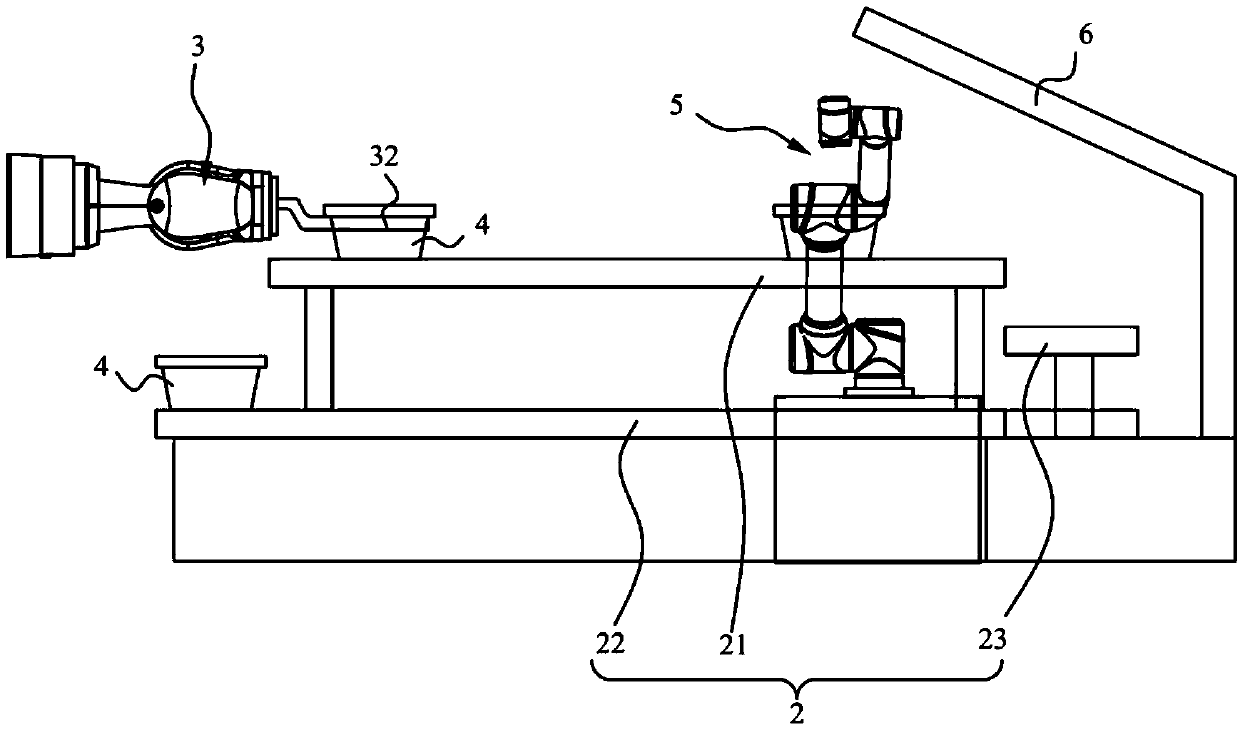

[0069] figure 1 A side view of the cargo picking system provided by the embodiment of the present invention, figure 2 The top view of the goods picking system provided for the embodiment of the present invention, such as figure 1 and 2 As shown, the embodiment of the present invention provides a cargo picking system, which is used to realize automatic picking of ordered goods from inventory containers to order boxes, and improve picking efficiency and accuracy.

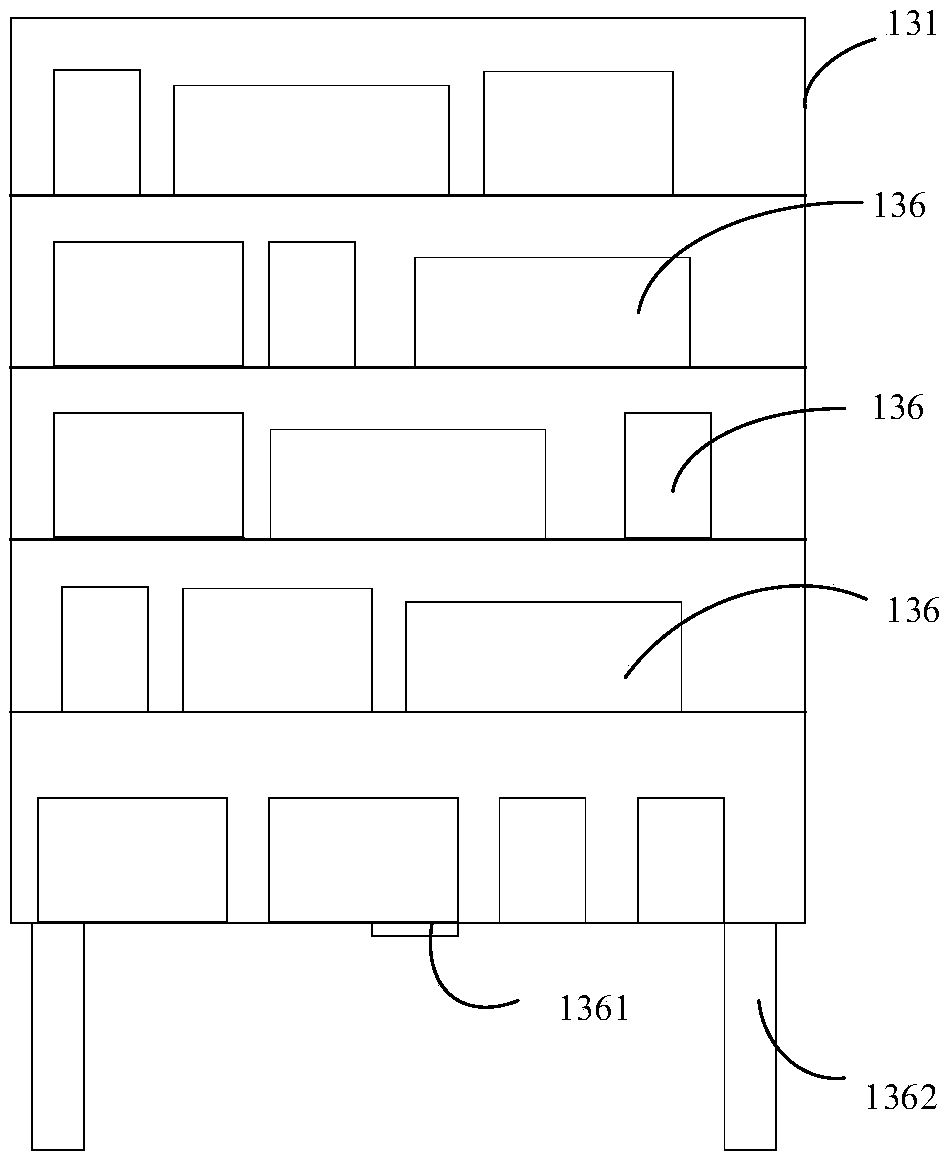

[0070] Specifically, the cargo picking system provided in this embodiment includes: a conveying device 2, which includes a first transmission line 21 and a second transmission line 22, and the first transmission line 21 and the second transmission line 22 are arranged in parallel; The target container 4 of the order goods is transported from the container storage area to the first transmission line 21, and the target container 4 is transported from the second transmission line 22 to the container storage area; the ...

Embodiment 2

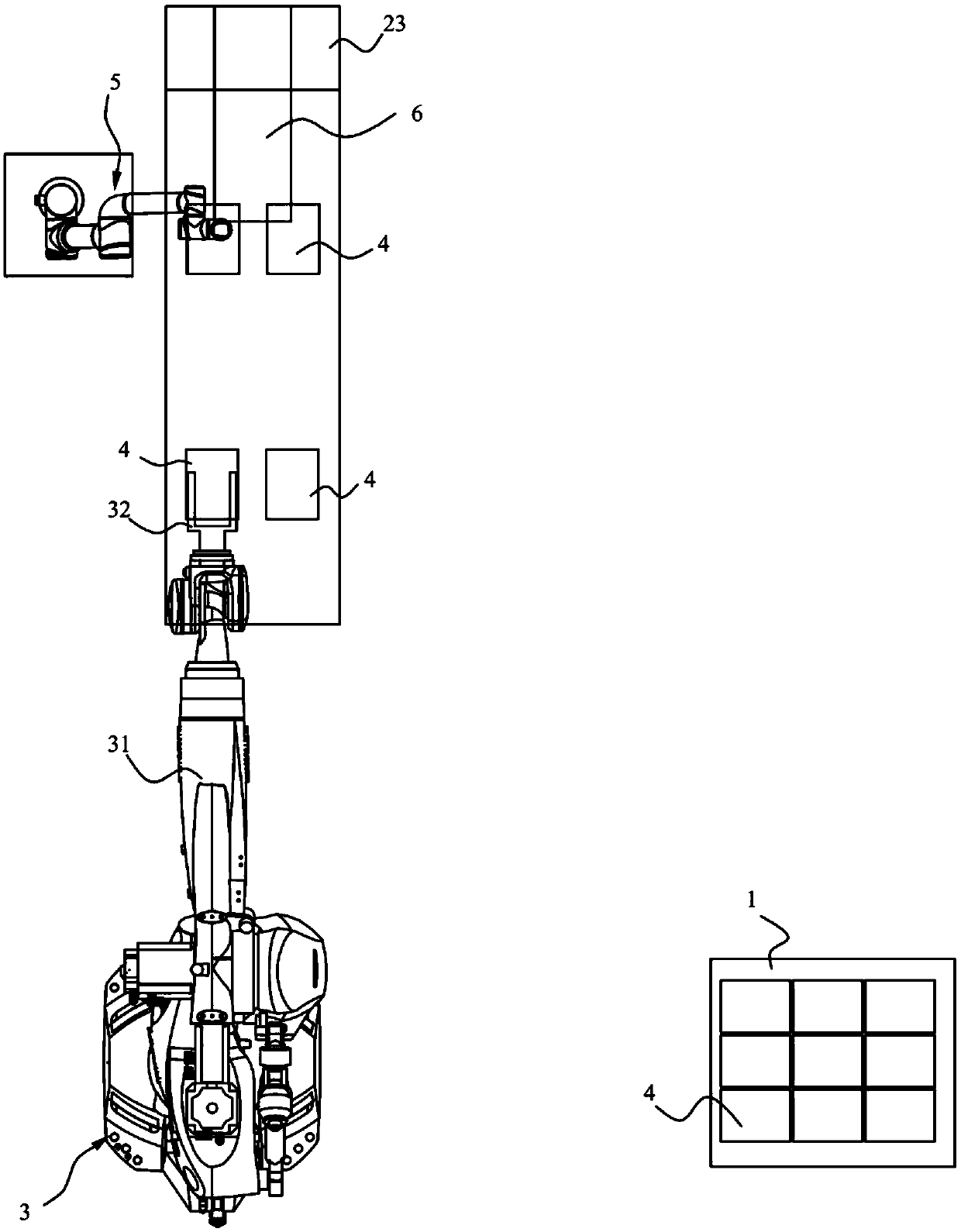

[0148] Figure 5 A side view of the structure of the cargo picking system provided by the embodiment of the present invention, Figure 6 The top view provided for the embodiment of the present invention, such as image 3 and Figure 4 As shown, the cargo picking system provided in this embodiment is basically the same as the cargo picking system provided in Embodiment 1, including a handling device 1, a conveying device 2, a container picking device 3, a picking device 5, a control system, and a detection system. The difference lies in that there are differences in the setting method of the picking device 5 and the control method of the control system.

[0149] In this embodiment, the picking area is set on the lifting platform 23 , and the picking device 5 is set on one side of the lifting platform 23 . Setting the picking area on the lifting platform 23 can separate the picking work of the picking device 5 from the operation of the first transmission line 21, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com