Low-torque arc-proof composite fabric and preparation method thereof

A composite fabric and anti-arc technology, applied in the textile field, can solve problems such as poor comfort and breathability, stuffy arc protective clothing, and arc protective fabrics that block heat conduction, and achieve good anti-arc and anti-explosion performance, good softness and comfort. The effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

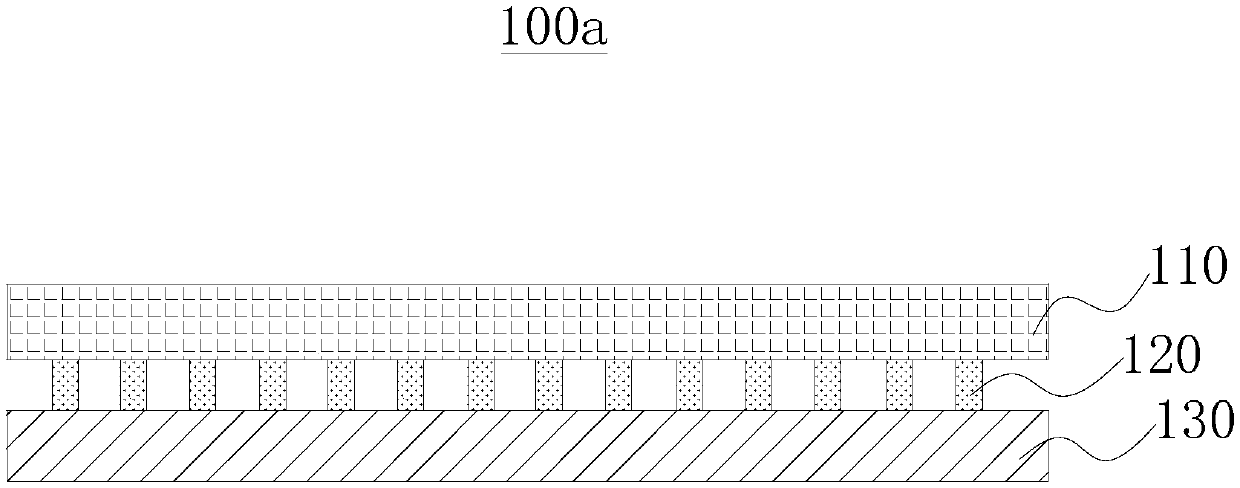

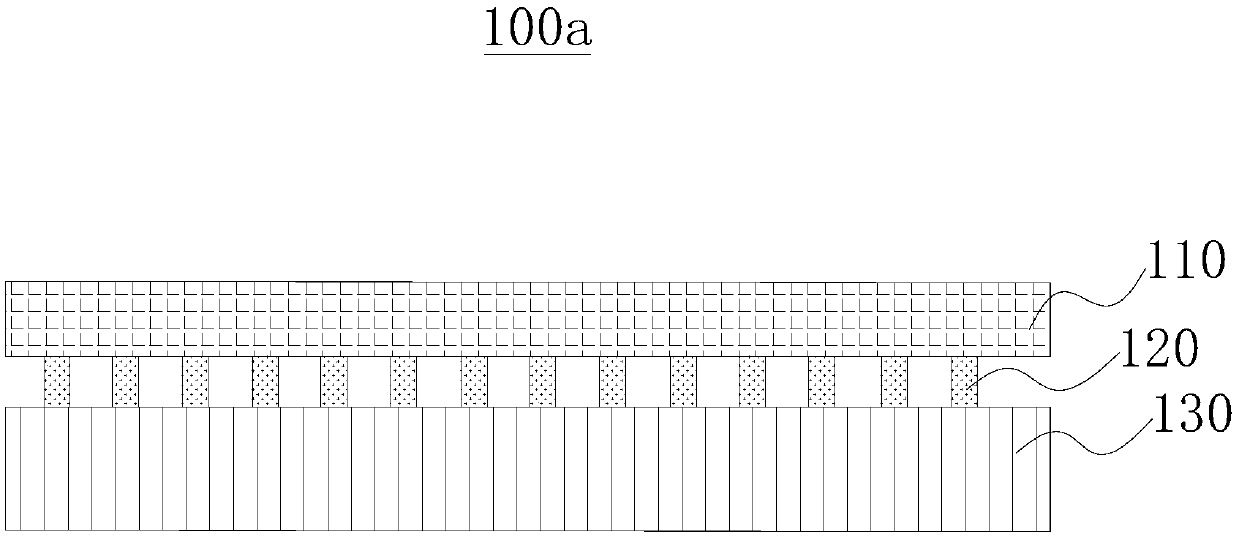

[0027]Some embodiments of the present invention also provide a method for preparing the above-mentioned low-torque arc-proof composite fabric, which includes: adhering and compounding the flame-retardant and heat-insulating layer and the antibacterial and heat-resistant layer through a flame-retardant adhesive connecting layer. Among them, the flame-retardant heat-insulating layer and the antibacterial heat-resistant layer are firstly blended by blending technology to obtain a separate fabric layer, and then bonded by a flame-retardant adhesive connection layer.

[0028] According to some embodiments, when the flame-retardant adhesive connection layer is bonded to the flame-retardant and heat-insulating layer and the antibacterial and heat-resistant layer, it can be glued by dispensing, so as to ensure that the laminated fabric has better air permeability and soft feel. At the same time, when there is a waterproof and breathable membrane, the flame-retardant and heat-resistant ...

Embodiment 1

[0035] The low-torque anti-arc composite fabric of this implementation includes a flame-retardant heat-insulating layer, a flame-retardant adhesive connection layer and an antibacterial heat-resistant layer. Fiber, 10 parts of aramid 1313, 5 parts of aramid 1414, 10 parts of polyimide and 1 part of conductive fiber are blended. 1 part of polyarylene oxadiazole fiber, 10 parts of aramid 1313 and 1 part of conductive fiber are blended, wherein, the yarn twist of the antibacterial heat insulation layer is 60 twists per 10 cm. Among them, the weight of the flame retardant heat insulation layer is 150g / m 2 , the weight of the antibacterial heat insulation layer is 50g / m 2 .

[0036] The preparation method of the low-torque anti-arc composite fabric includes: adhering and compounding the flame-retardant heat-insulating layer and the antibacterial heat-resistant layer obtained by blending according to the above-mentioned raw material ratio through a flame-retardant glue connecting ...

Embodiment 2

[0038] The low-torque anti-arc composite fabric of this implementation includes a flame-retardant heat-insulating layer, a flame-retardant adhesive connection layer and an antibacterial heat-resistant layer. Polyvinyl chloride, 30 parts of aramid 1313, 15 parts of aramid 1414, 30 parts of polyimide and 3 parts of conductive fiber are blended. The antibacterial and heat-resistant layer is made of 60 parts of silicon nitrogen flame retardant viscose, 40 parts of acrylic chloride fiber, 30 parts of polyarylene oxadiazole fiber, 30 parts of aramid 1313 and 3 parts of conductive fiber are blended, and the twist of the yarn of the antibacterial heat insulation layer is 65 twists per 10 cm. Among them, the weight of the flame retardant insulation layer is 400g / m 2 , the weight of the antibacterial heat insulation layer is 200g / m 2 .

[0039] The preparation method of the low-torque anti-arc composite fabric includes: adhering and compounding the flame-retardant heat-insulating laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com