Welding seam visual tracking system based on laser structured light and method

A technology of visual tracking and laser structure, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to shorten the production cycle, avoid damage, and improve the quality of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the present invention, through mechanical fixture design, camera selection, weld seam tracker structure design, and in-depth research on the interference filtering algorithm of visual images, the theoretical basis of image reconstruction of variable base surface is analyzed, and the weld seam space is achieved through the algorithm design of plane and space. The purpose of feature reconstruction: Utilize the experimental platform constituted by the present invention to design welding seam recognition experiments in various complex situations, and further improve the designed algorithm, so that the welding seam recognition can reach the practical stage.

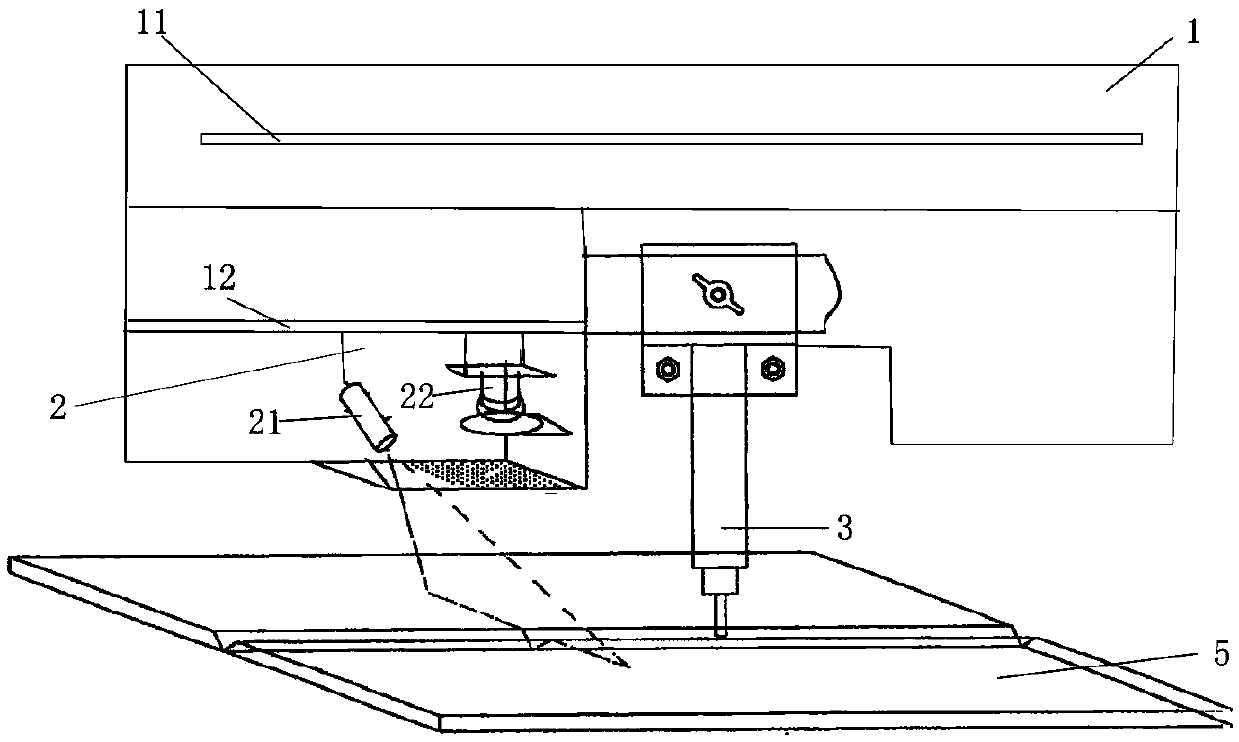

[0047] In the process of robot welding, in order to ensure that the welding torch can be above the center of the weld seam in real time, such as figure 1 , figure 2 and image 3 As shown, the welding seam visual tracking system based on laser structured light includes a visual tracking module 2 , a robot module 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com