A hydraulic cylinder inner wall cleaner

A technology for hydraulic cylinders and cleaners is applied in the field of cleaners and inner wall cleaners of hydraulic cylinders. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

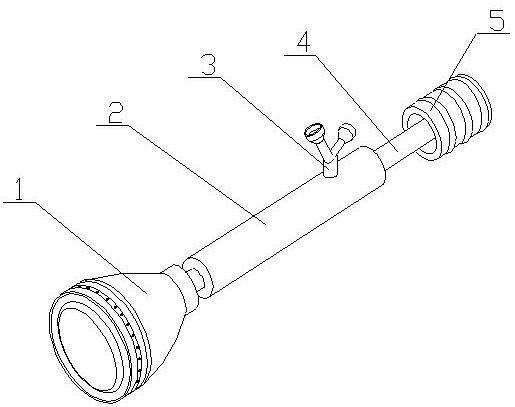

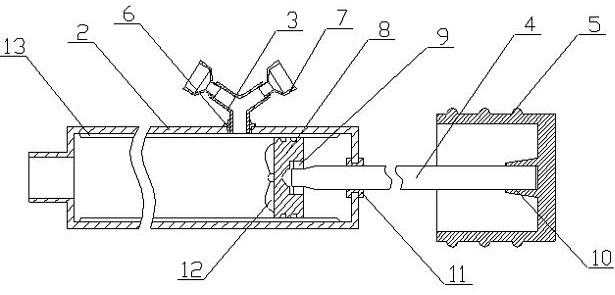

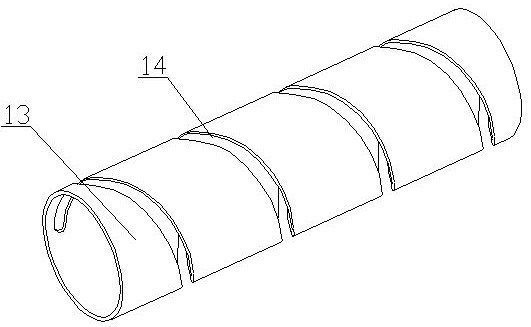

[0018] A hydraulic cylinder inner wall cleaner of the present invention is realized as follows: a hydraulic cylinder inner wall cleaner of the present invention consists of a cleaning shell (1), a hollow pipe (2), a connecting pipe (3), a piston rod (4), Handle (5), connecting rubber sleeve (6), connecting screw sleeve (7), piston (8), bearing (9), clamping sleeve (10), sealing ring (11), vane (12), inner guide sleeve (13), thread groove (14), filter plug (15), diverter block (16), rubber ring (17), nozzle hole (18) and end cap (19), and one end of the hollow tube (2) There is a connecting pipe in the middle, which communicates with the hollow pipe (2). The cleaning shell (1) is placed on the connecting pipe and communicates with the connecting pipe. The diameter of the cleaning shell (1) is from one end to the other. One end gradually increases, the filter plug (15) is placed inside the cleaning housing (1), and corresponds to the connecting pipe, the support column is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com