Inversion type pre-filter

A pre-filter, inverted technology, applied in the direction of fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve problems such as user troubles, prolong service life, improve convenience, and clean and discharge sewage. Synchronized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

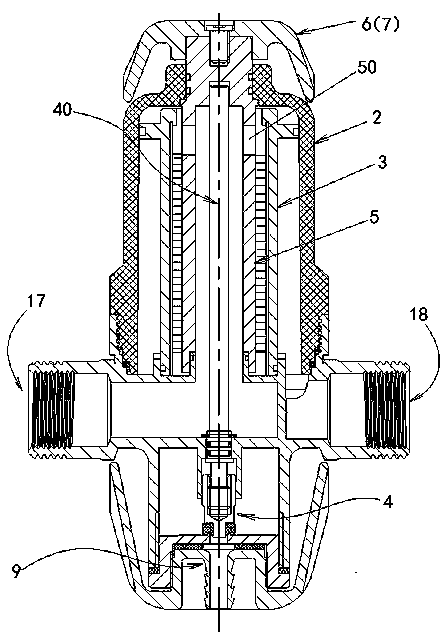

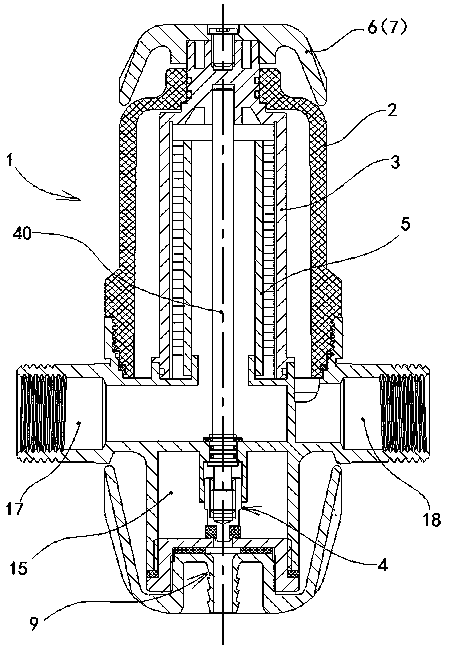

[0029] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, an inverted pre-filter includes a pre-filter body 19, and the pre-filter body 19 includes a connecting part 1, a bottle body 2, a filter cartridge 3 and a flexible scraper in the shape of a hollow cylinder as a whole. Cleaning device 5.

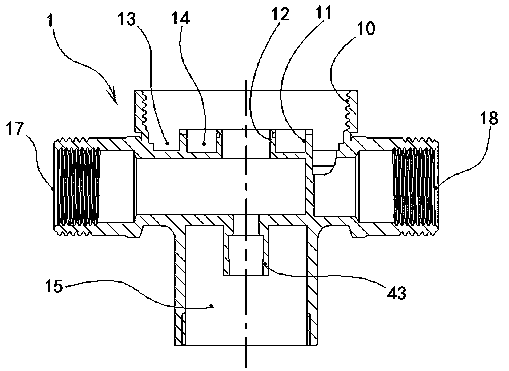

[0030]The upper end of the connecting part 1 is provided with three bottle body interface 10, filter cartridge interface 11 and inner water inlet interface 12 arranged in sequence from outside to inside in concentric circles. The three concentric circle interfaces mutually form an outer ring cavity 13 and an inner ring cavity. An annular cavity 14, a sewage discharge chamber 15 is arranged inside the bottom end of the connecting part 1, and the sewage discharge chamber 15 is connected with the inner annular cavity 14 at its upper end, and a sewage discharge device 4 is also arranged therein, and the sewage discharge device 4 includes...

Embodiment 2

[0037] Such as figure 2 , Figure 5 , Figure 9 , Figure 10 As shown, an O-ring sealing structure 30 is provided on the bottom and top periphery of the filter cartridge 3 and forms a static sealing fit with the inner wall of the bottle body 2 and the inner wall of the filter cartridge interface 11; It is in the shape of a hollow cylinder, and its bottom port and the inner water inlet interface 12 form a dynamic sealing relationship. The top of the bottle body 2 is provided with a groove 20 and a through hole 21. The top of the flexible cleaning device 5 is set on the The groove 20 and the through hole 21 form a dynamic sealing fit relationship, and its outer port is connected with a hand wheel 6 or an electric actuator 7, and a polygonal inner surface is arranged at the top of the flexible scraping and cleaning device 5. Hole 8, the section of the outer end of the valve stem 40 is also polygonal and adapted to the inner hole 8 (in this embodiment, the polygon is hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com