Blast-contained fine cigarette peeling device and method

A technology for thin cigarettes and popping beads, which is applied in the fields of tobacco, paper cigarette manufacturing, and application, can solve the problems of changing tobacco taste, low silk yield, filter damage, etc. Effects of Intrinsic Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

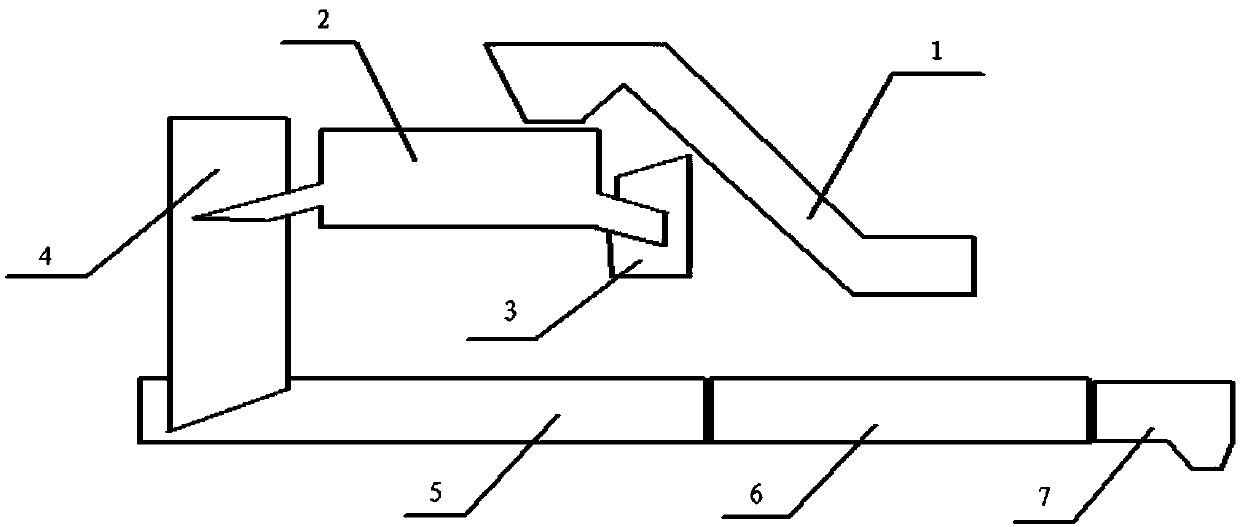

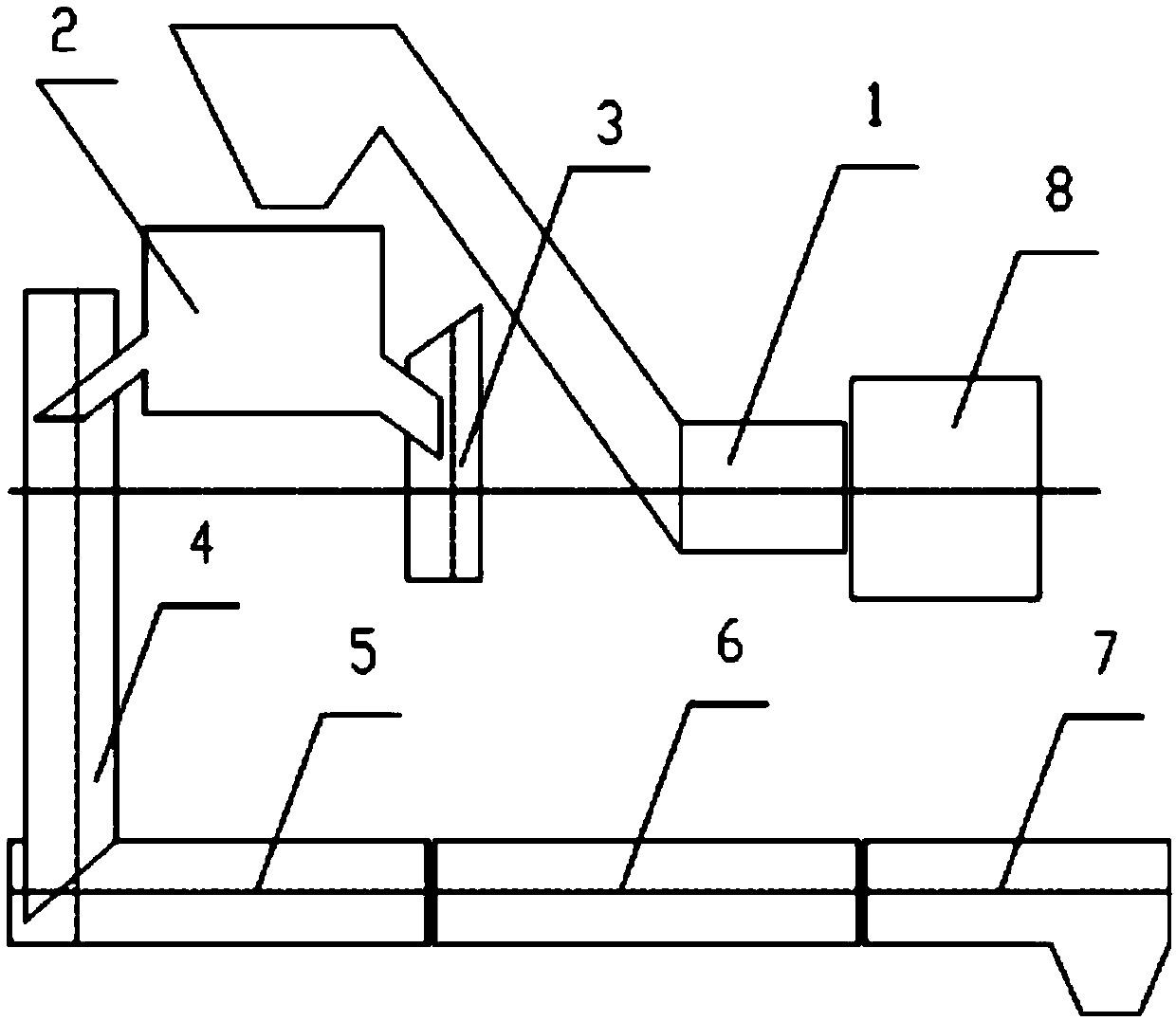

[0034] image 3 Shown is a schematic structural view of one embodiment of the device for stripping fine cigarettes containing explosive beads according to the present invention. The device includes a quantitative feeder 1, a FY37 type waste cigarette processing machine 2, a paper vibrating tank 3, and a screening device 4. Conveyor belt 5, vibrating tank 6, spectrum remover 7, fine cigarette sorting mechanism 8 containing explosive beads, the fine cigarette sorting mechanism 8 containing explosive beads is set in front of quantitative feeding machine 1, FY37 type The waste cigarette processing machine 2 is provided with a filter frame column 13 .

[0035] Such as Figure 4 As shown, the described fine cigarette sorting mechanism 8 containing explosive beads includes a feed port 31, a conveying track 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com