A Fast Reactor Core Coolant Flow Distribution Method Based on Pressure Drop Compensation

A technology of flow distribution and pressure drop compensation, which is applied in the direction of reactors, reactor fuel elements, and reduction of greenhouse gases, etc., can solve the problems of reactor economic decline, transitional cooling of peripheral components, etc., and achieve uniform overall flow distribution, uniform distribution, and effective cooling uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

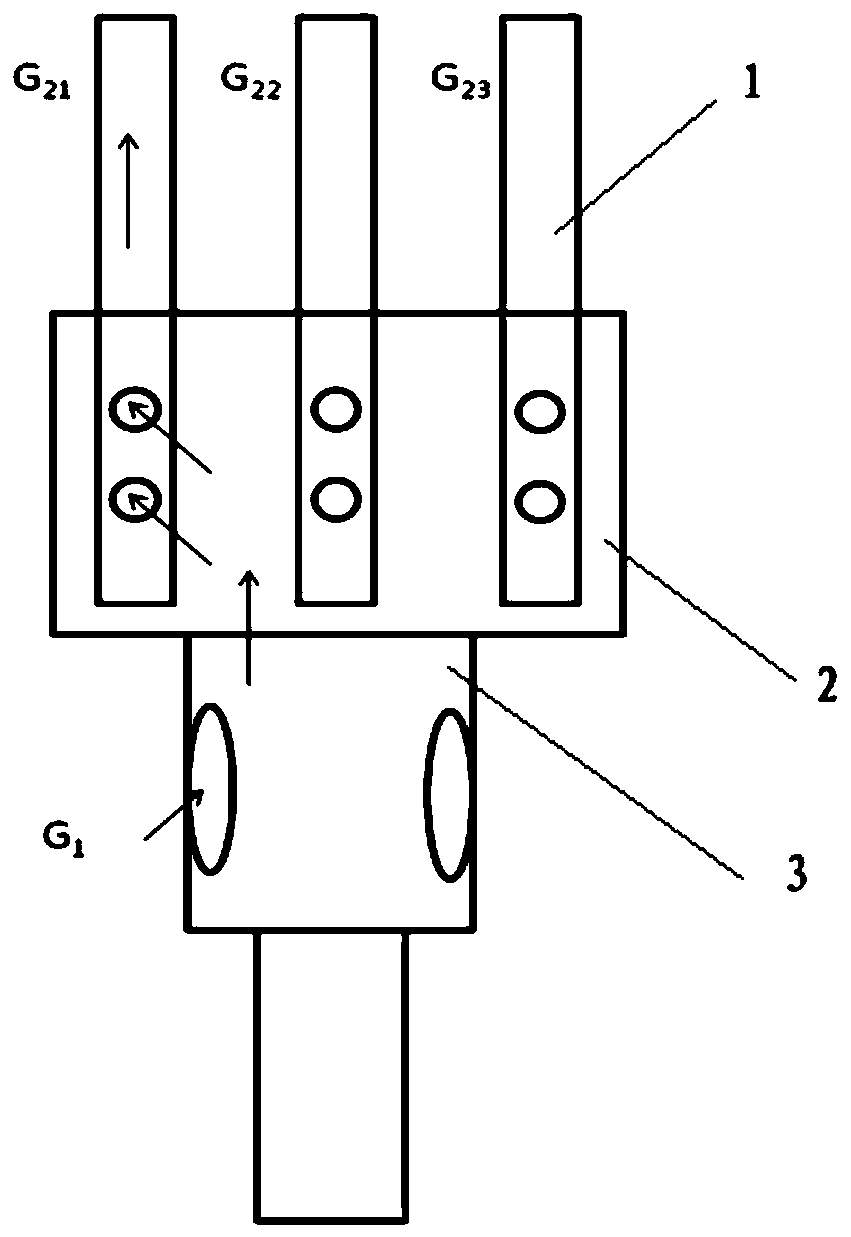

[0031] The present application will be further elaborated below in conjunction with the accompanying drawings and specific implementation methods.

[0032] A fast reactor core coolant flow distribution method based on pressure drop compensation, the method comprising the following steps:

[0033] (1) Count the number of small grille headers, and number them sequentially from 1 to K from the middle to the periphery;

[0034] Since there are 7 components on each small grid header, the components on each small grid header are recorded as K-1~K-7;

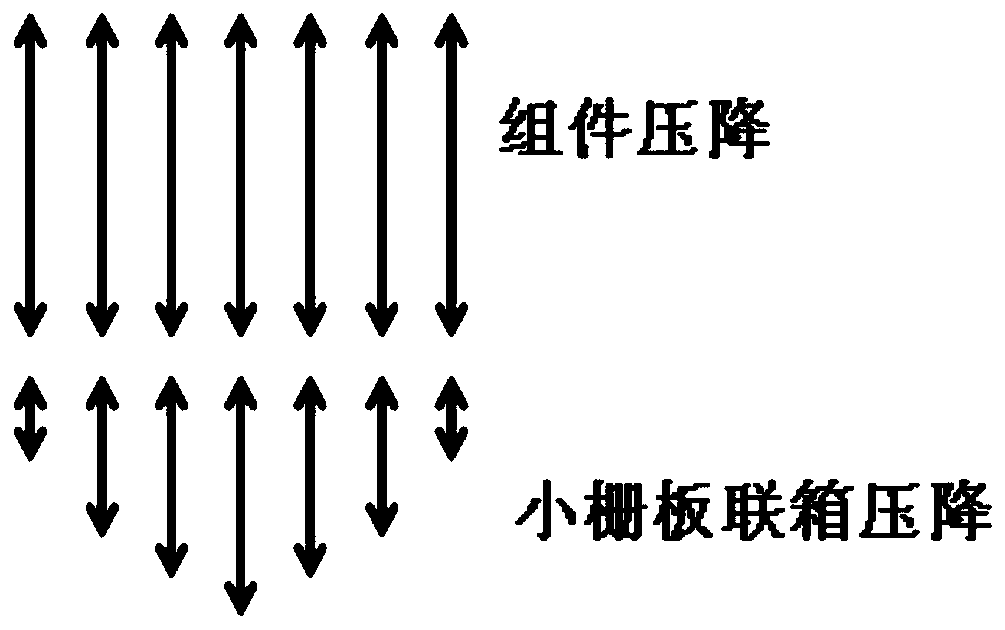

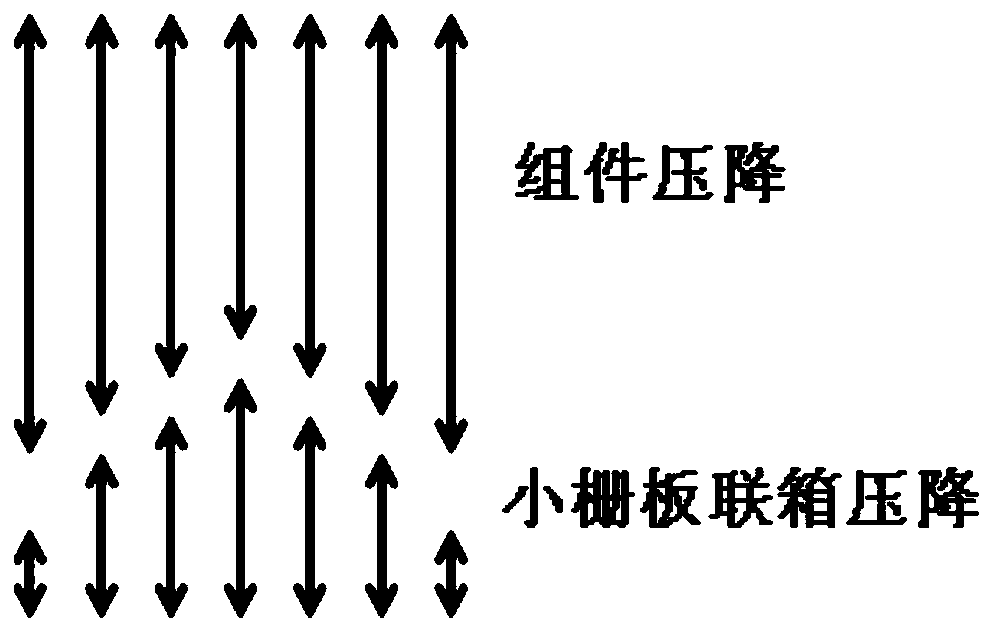

[0035] (2) Draw the relationship curve between the core assembly in the outer fuel zone and the minimum coolant flow rate

[0036] Calculate the minimum coolant flow required by the component according to the power of each component; use the component number as the abscissa and the minimum coolant flow as the ordinate to draw the minimum coolant flow curve of the core component and the minimum coolant flow, respectively Obtain the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com