Method for testing chip parameters at different temperatures

A test method and chip technology, which is applied in the direction of electronic circuit testing, measuring electricity, measuring devices, etc., can solve the problems of high cost, large human resources, low efficiency, etc., and achieve the effect of reducing workload and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] like figure 1 Shown is a flowchart of a method for testing chip parameters at different temperatures according to a preferred embodiment of the present invention. The test method utilizes a heat flow shield and chip automated testing equipment. The heat flow shield includes a sensor, and the sensor is used to measure the chip temperature. The chip automatic testing equipment is connected with the chip. The execution subject in this embodiment is the automatic chip testing equipment, which specifically includes the following steps.

[0025] In step a1, the chip automated testing equipment sends a set temperature signal to the heat flow shield, wherein the set temperature signal includes a currently preset temperature point.

[0026] In step a2, the chip automated testing equipment receives the temperature setting completion signal sent by the heat flow cover, wherein the temperature setting completion signal is: after the heat flow cover receives the set temperature sig...

Embodiment 2

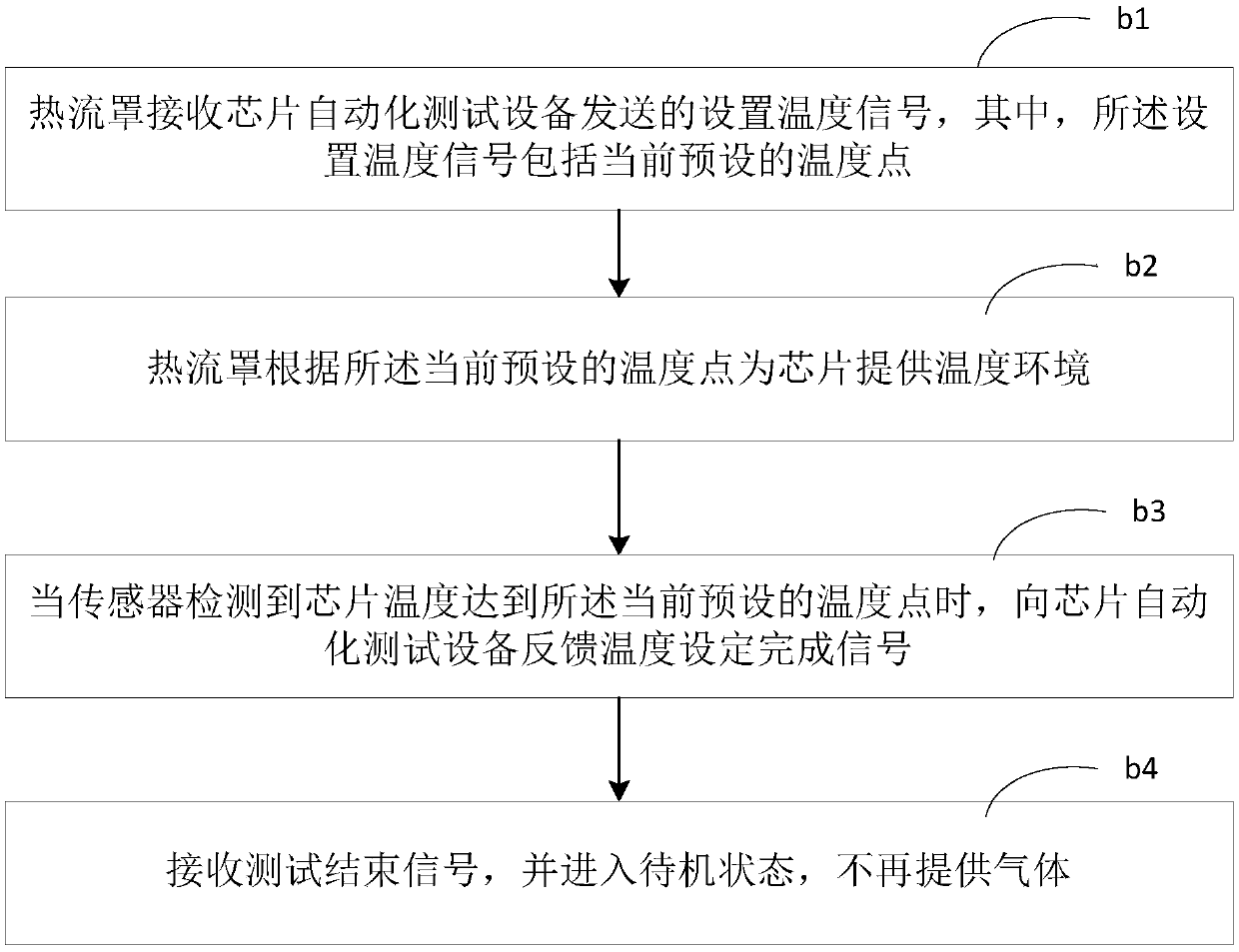

[0036] like figure 2 Shown is a flow chart of a method for testing chip parameters at different temperatures according to another preferred embodiment of the present invention. The test method utilizes a heat flow shield and chip automated testing equipment. The heat flow shield includes a sensor, and the sensor is used to measure the chip temperature. The chip automatic testing equipment is connected with the chip. The execution body in this embodiment is a heat flow shield, which specifically includes the following steps.

[0037] In step b1, the heat flow shield receives a set temperature signal sent by the chip automation test equipment, wherein the set temperature signal includes a currently preset temperature point.

[0038] In step b2, the heat flow shield provides a temperature environment for the chip according to the current preset temperature point.

[0039] Specifically, after the heat flow hood is turned on, the dry compressed air is sucked in through the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com