Method for preparing ruthenium catalyst supported on porous carbon

A technology of porous carbon and catalyst is applied in the field of catalyst preparation of porous carbon supported ruthenium, which can solve the problems of high price and low reserves, and achieve the effects of improving catalytic activity, simple preparation process, and saving cost and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

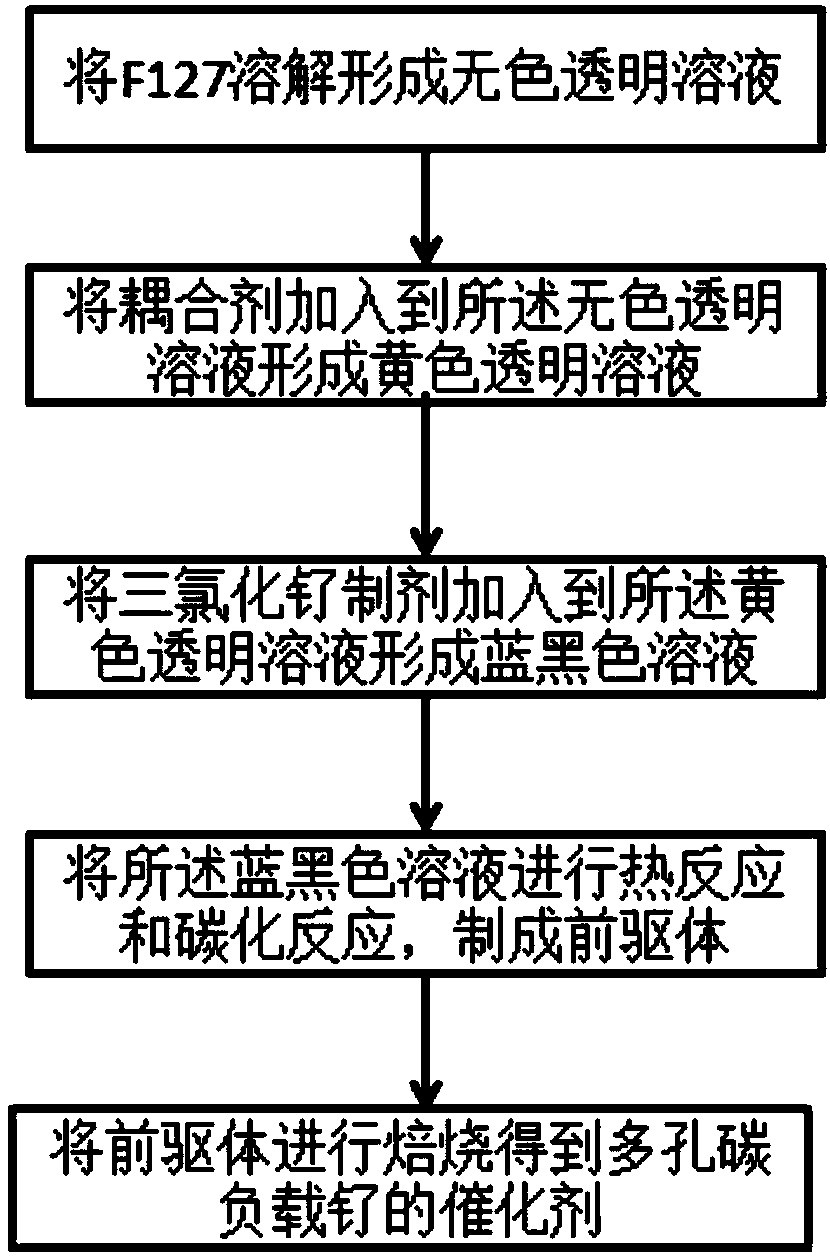

[0043] Step 1. Dissolve 1g of F127 in a mixed solution of ethanol and ethylene glycol and stir at 40°C for 10 minutes. After the F127 is completely dissolved, a colorless and transparent solution is obtained; wherein, the volume ratio of ethanol and ethylene glycol in the mixed solution is: V 乙醇 :V 乙二醇 = 3:2;

[0044] Step 2, adding 0.18 g of 8-hydroxyquinoline to the colorless transparent solution under continuous stirring at 40°C, and waiting until the 8-hydroxyquinoline is completely dissolved to obtain a yellow transparent solution;

[0045] Step 3, 6.25mL of ruthenium trichloride (RuCl 3 ) and ethanol were added to the yellow transparent solution, and stirred continuously for 4 hours at a temperature of 40° C. to finally obtain a blue-black solution; wherein, ruthenium trichloride (RuCl 3 ) and ethanol mixture, RuCl 30.0037g / mL;

[0046] Step 4, transfer the blue-black solution to a 100mL high-pressure hydrothermal kettle, and perform a thermal reaction. The process ...

Embodiment 2

[0050] The reaction is basically the same as in Example 1, except that in step 4, in the process conditions of thermal reaction, the reaction temperature is 120°C.

Embodiment 3

[0052] The reaction is basically the same as in Example 1, except that in step 4, in the process conditions of the thermal reaction, the reaction temperature is 200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com