Special clamp for valve element coating

A special fixture and spool technology, applied in the field of tooling and fixtures, can solve problems such as difficult clamping, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

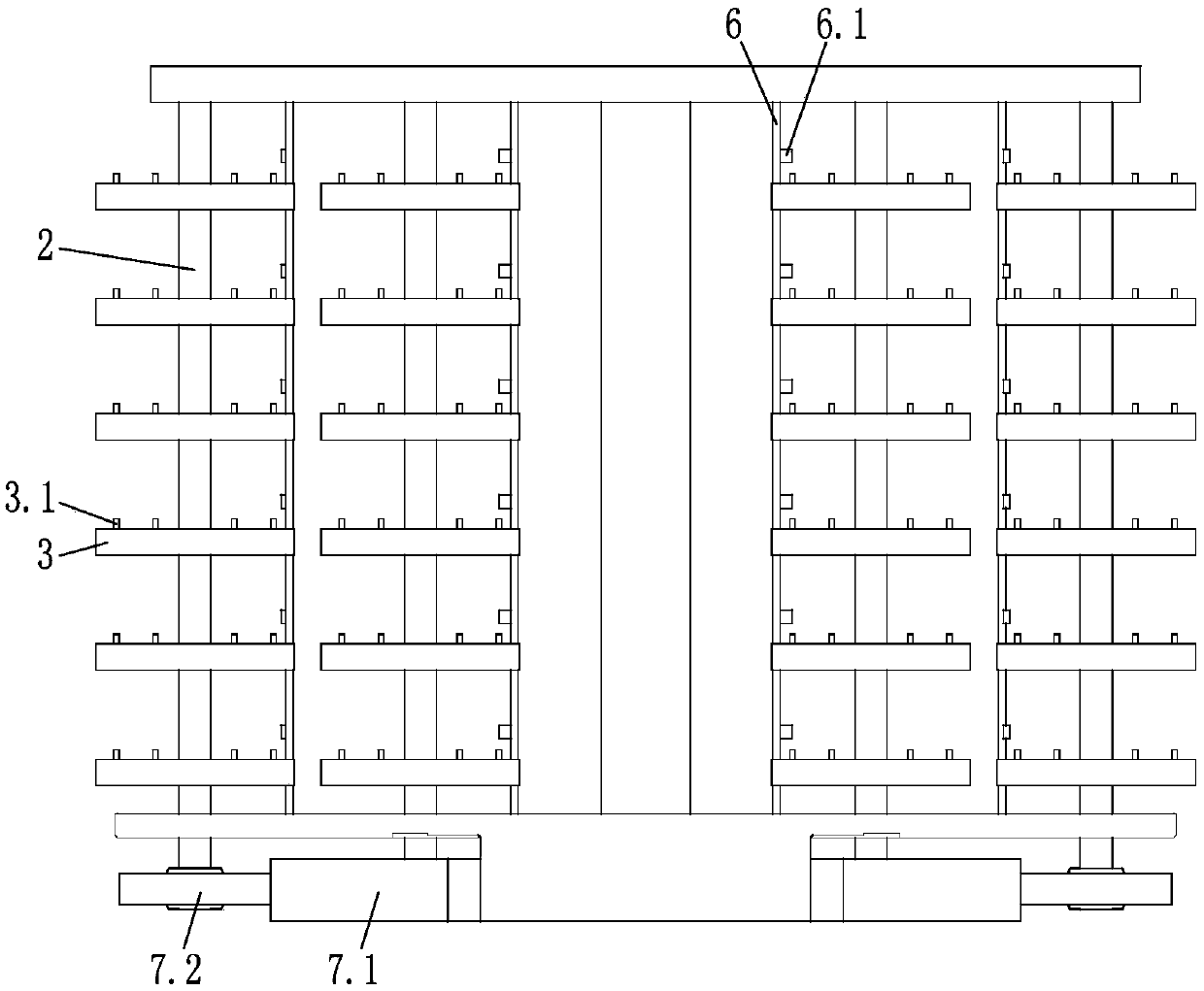

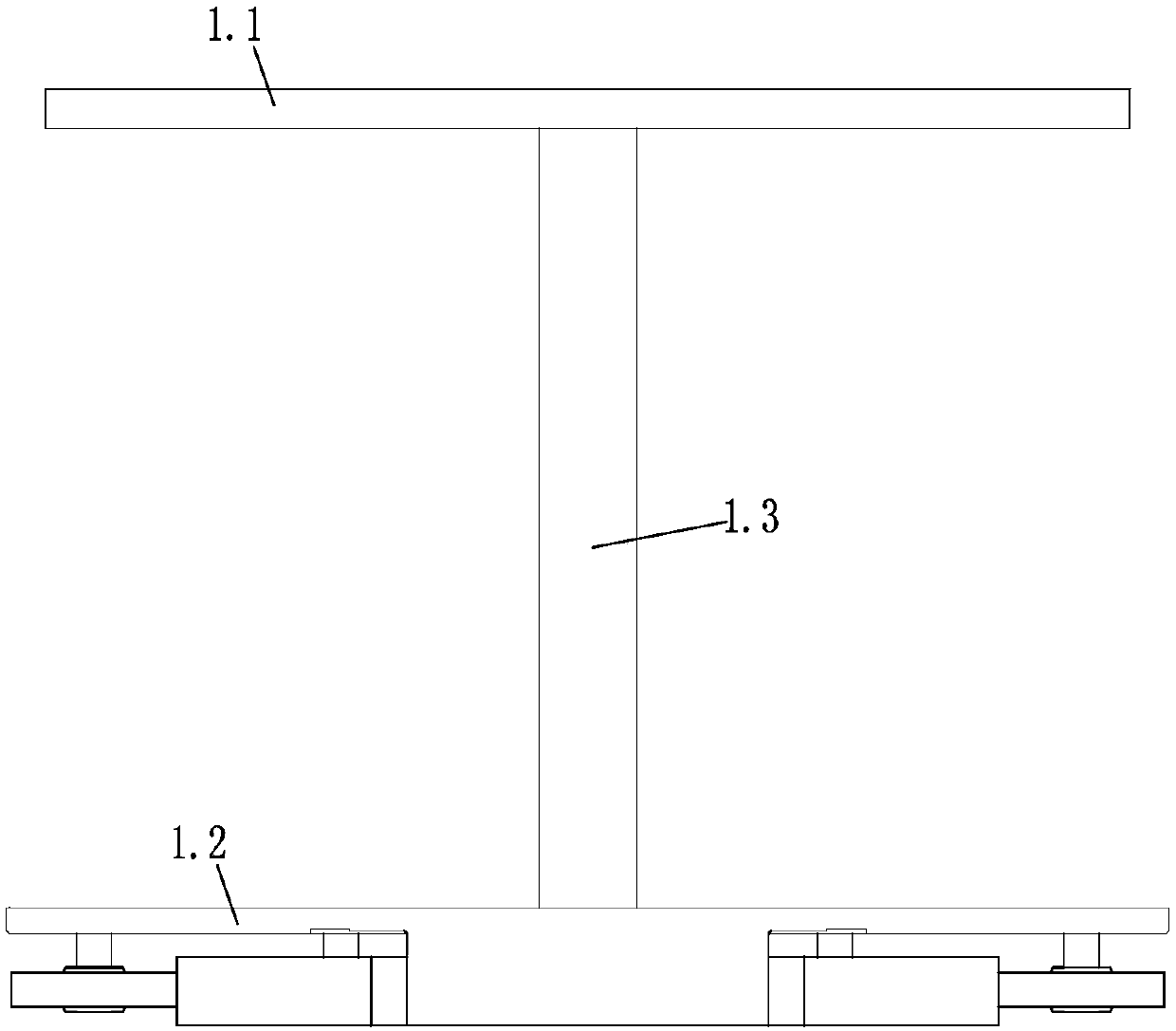

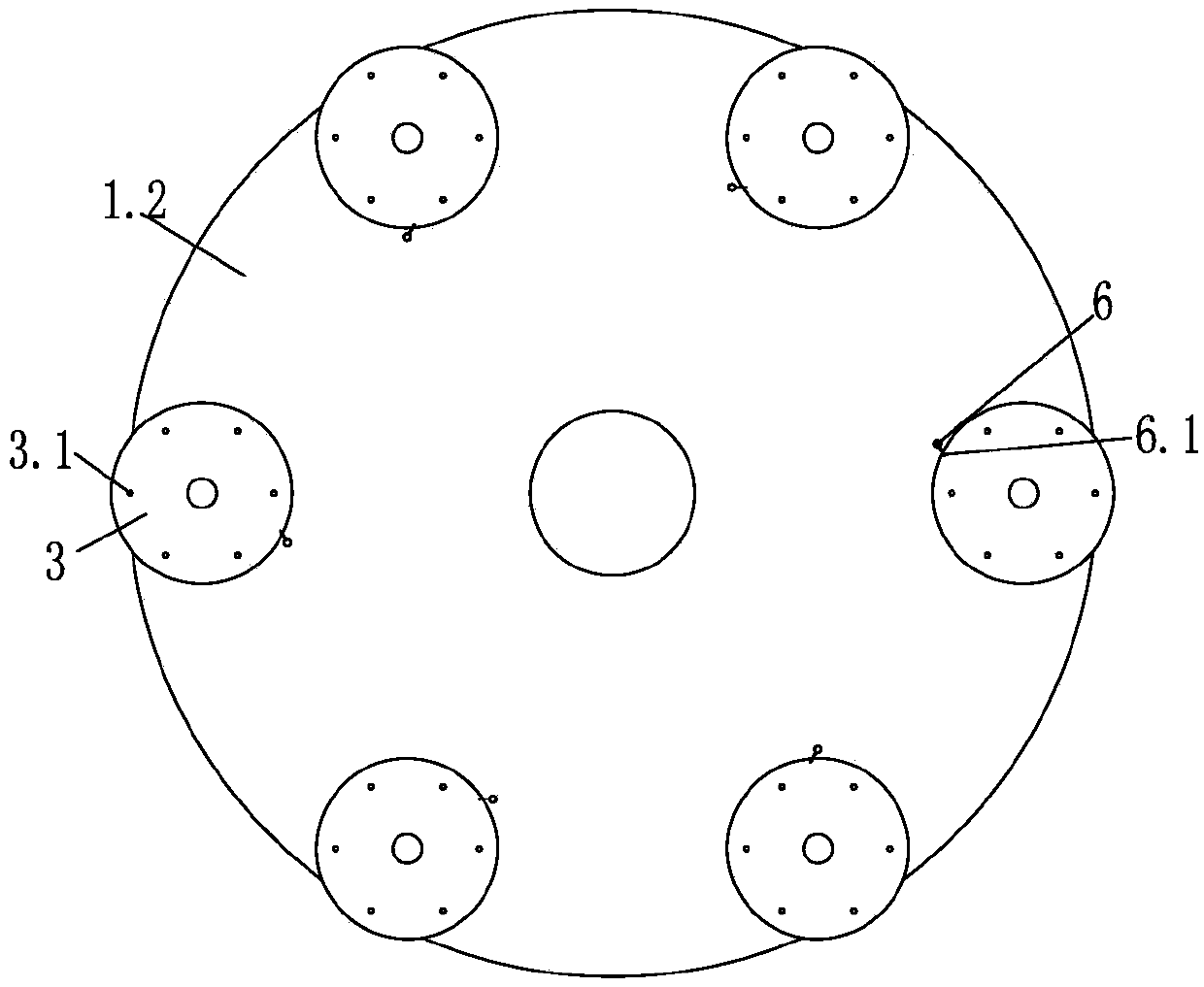

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

[0027] Unbalanced magnetron sputtering ion plating equipment is currently a popular coating equipment; its working principle is based on unbalanced magnetron sputtering, that is, the magnetic field of a certain magnetic pole is strengthened or weakened by the magnetic field of the opposite magnetic pole of another polarity, resulting in The "non-equilibrium" of the magnetic field distribution is ensured; while ensuring that the horizontal magnetic field component on the target surface effectively constrains the movement of secondary electrons and maintains a stable magnetron sputtering discharge, another part of the electrons generates a longitudinal magnetic field perpendicular to the target surface along the strong magnetic poles. The electrons that escape from the target surface fly to the coating ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap