Production method of improving water soluble phosphorus content of phosphate fertilizer soluble in citric acid

A production method and citrate-soluble technology, applied in nitrogen fertilizer, fertilization equipment, fertilizer mixture, etc., can solve the problems of sodium dodecylbenzenesulfonate strong foaming power, unfavorable industrial production, unfavorable reaction, etc., and achieve an increase in nitrogen content , Nitrogen loss reduction, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

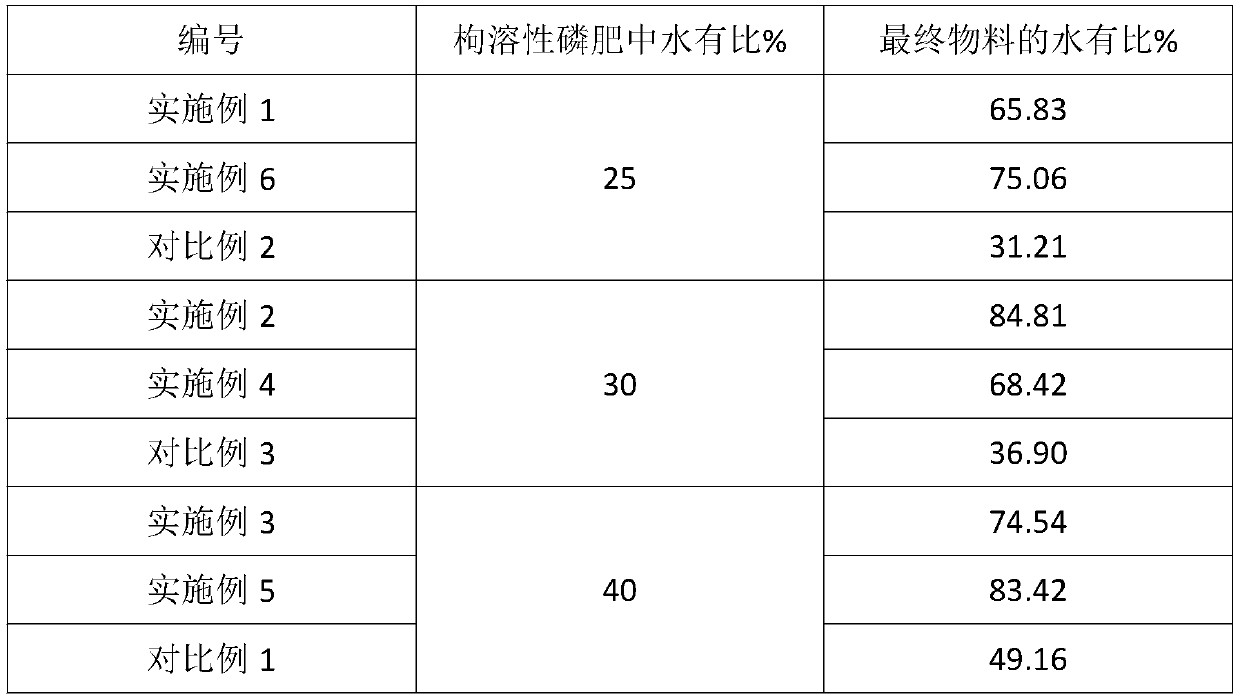

Embodiment 1

[0030] S1: Weigh 100 grams of urea sulfate (urea: sulfuric acid = 2.2:1) and add it to 1000 grams of citrate-soluble phosphate fertilizer (the ratio of water-soluble phosphorus to available phosphorus is 25%), and mix and react at 60°C for 50 minutes to obtain material A;

[0031] S2: Material A was cured at 50°C for 60 minutes to obtain material B;

[0032] S3: Material B was aged at 45°C for 1 day to obtain the primary product of compound fertilizer, the ratio of water-soluble phosphorus to available phosphorus was 65.83%.

Embodiment 2

[0034] S1: Weigh 300 grams of urea sulfate (urea: sulfuric acid = 1.22:1) and add it to 1000 grams of citrate-soluble phosphate fertilizer (the ratio of water-soluble phosphorus to available phosphorus is 30%), and mix and react at 75°C for 70 minutes to obtain material A;

[0035] S2: Material A was cured at 55°C for 90 minutes to obtain material B;

[0036] S3: Material B was matured at 50°C for 2 days to obtain the primary product of compound fertilizer, the ratio of water-soluble phosphorus to available phosphorus was 84.81%.

Embodiment 3

[0038] S1: Weigh 400 grams of urea sulfate (urea: sulfuric acid = 0.92:1) and add it to 1000 grams of citrate-soluble phosphate fertilizer (the ratio of water-soluble phosphorus to available phosphorus is 40%), and mix and react at 90°C for 90 minutes to obtain material A;

[0039] S2: Material A was cured at 60°C for 120 minutes to obtain material B;

[0040] S3: Material B was matured at 55°C for 3 days to obtain the primary product of compound fertilizer, the ratio of water-soluble phosphorus to available phosphorus was 74.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com