Non-homogenous low-carbon microlite insulating mould coating and preparation method thereof

A thermal insulation coating and non-homogeneous technology, applied in the field of coatings, can solve the problems of poor thermal insulation performance, unfavorable environmental protection and high price, and achieve the effects of improving antibacterial performance, reducing energy loss and moderate air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

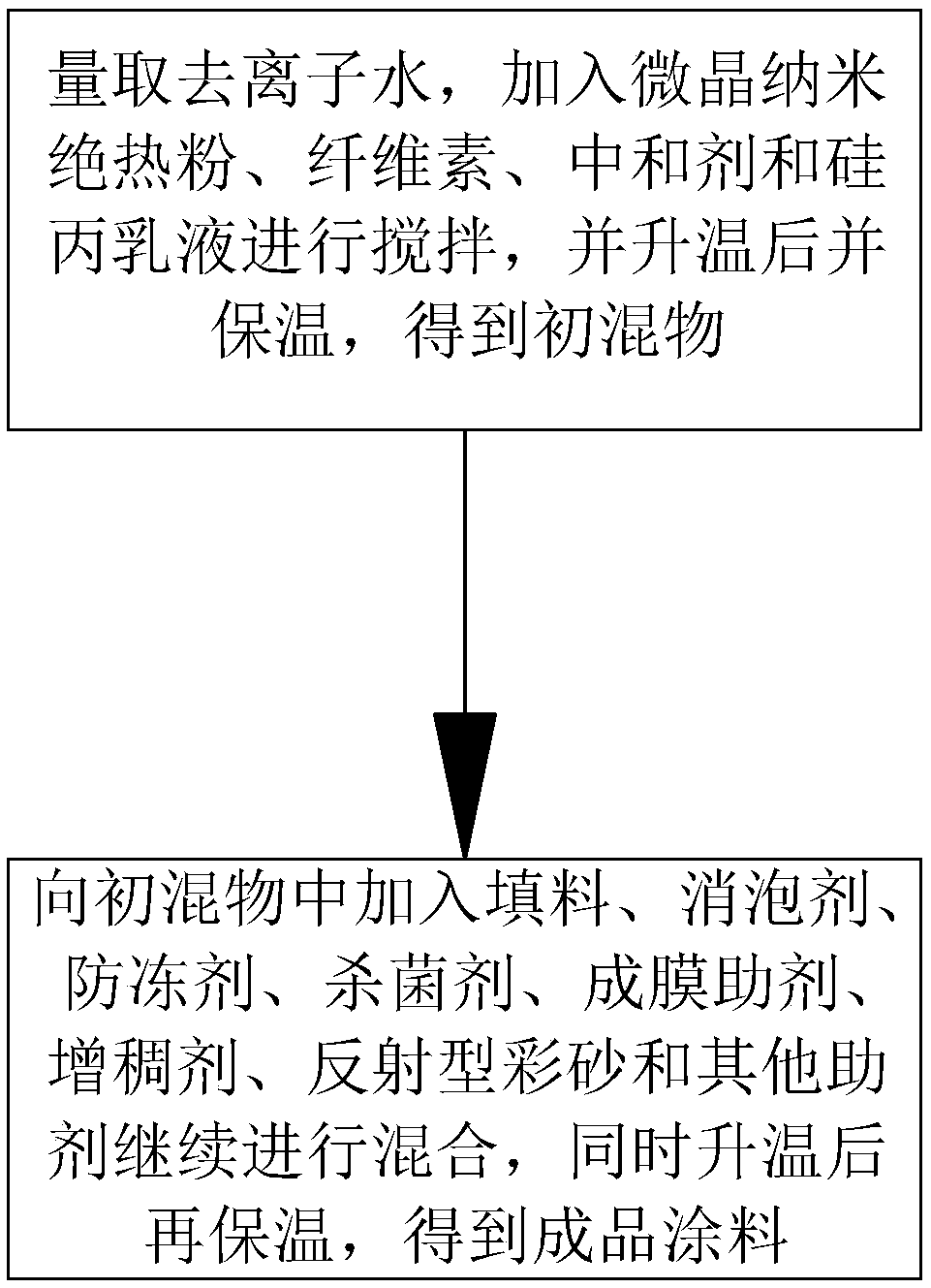

[0034] A preparation method of a non-homogeneous low-carbon microcrystalline stone thermal insulation coating, comprising the following steps:

[0035] Step 1. First measure 100Kg of deionized water, then add 20Kg of microcrystalline nano-insulation powder, 2Kg of cellulose, 1Kg of neutralizing agent and 5Kg of silicon acrylic emulsion for stirring, while raising the temperature to 60°C, stirring at 400rpm, stirring The time continued for 2h to obtain the primary mixture;

[0036] Step 2: Add filler 5Kg, defoamer 0.5Kg, antifreeze 10Kg, fungicide 1Kg, film-forming aid 10Kg, thickener 5Kg, reflective colored sand 700Kg and other additives to the initial mixture in step 1 2Kg, continue to mix, while raising the temperature to 90°C, the stirring speed is 600rpm, and the stirring time lasts for 2h, and the finished coating is obtained after being fully dispersed.

[0037]Among them, the microcrystalline thermal insulation nanopowder can be purchased from Huntsman, UK. In additio...

Embodiment 2

[0040] A preparation method of a non-homogeneous low-carbon microcrystalline stone thermal insulation coating, comprising the following steps:

[0041] Step 1. First measure 110Kg of deionized water, then add 40Kg of microcrystalline nano-insulation powder, 3Kg of cellulose, 2Kg of neutralizer and 15Kg of silicon acrylic emulsion for stirring, while raising the temperature to 70°C, stirring at 600rpm, stirring The time continued for 3h to obtain the primary mixture;

[0042] Step 2: Add filler 8Kg, defoamer 2Kg, antifreeze 20Kg, bactericide 2Kg, film-forming aid 15Kg, thickener 8Kg, reflective colored sand 750Kg and other additives 3Kg to the initial mixture in step 1 , continue to mix, while raising the temperature to 100°C, the stirring speed is 800rpm, and the stirring time lasts for 4h, and the finished coating is obtained after being fully dispersed.

Embodiment 3

[0044] A preparation method of a non-homogeneous low-carbon microcrystalline stone thermal insulation coating, comprising the following steps:

[0045] Step 1. First measure 105Kg of deionized water, then add 30Kg of microcrystalline nano-insulation powder, 2.5Kg of cellulose, 1.5Kg of neutralizer and 10Kg of silicon-acrylic emulsion for stirring, while raising the temperature to 65°C, and the stirring speed is 500rpm , the stirring time continued for 2.5h to obtain the primary mixture;

[0046] Step 2. Add filler 6Kg, defoamer 1Kg, antifreeze 15Kg, bactericide 1.5Kg, film-forming aid 12Kg, thickener 7Kg, reflective colored sand 720Kg and other additives to the primary mixture in step 1 2.5Kg, continue to mix, at the same time increase the temperature to 95°C, the stirring speed is 700rpm, and the stirring time lasts for 3h, and the finished coating is obtained after being fully dispersed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com