A method for preparing hydrophobic silicon dioxide by using fumed silicon dioxide

A technology of fumed silica and silica, which is applied in the direction of silica and silica, can solve the problems of silica hydrophobicity instability, complex process, and application limitations, and avoid castor Catalyst failure, simple process, and easy-to-achieve reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

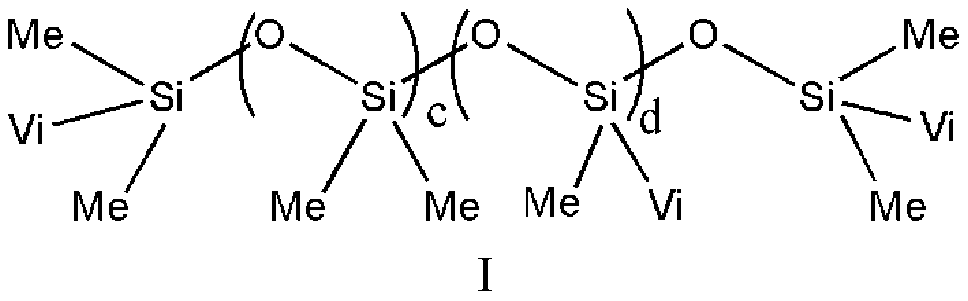

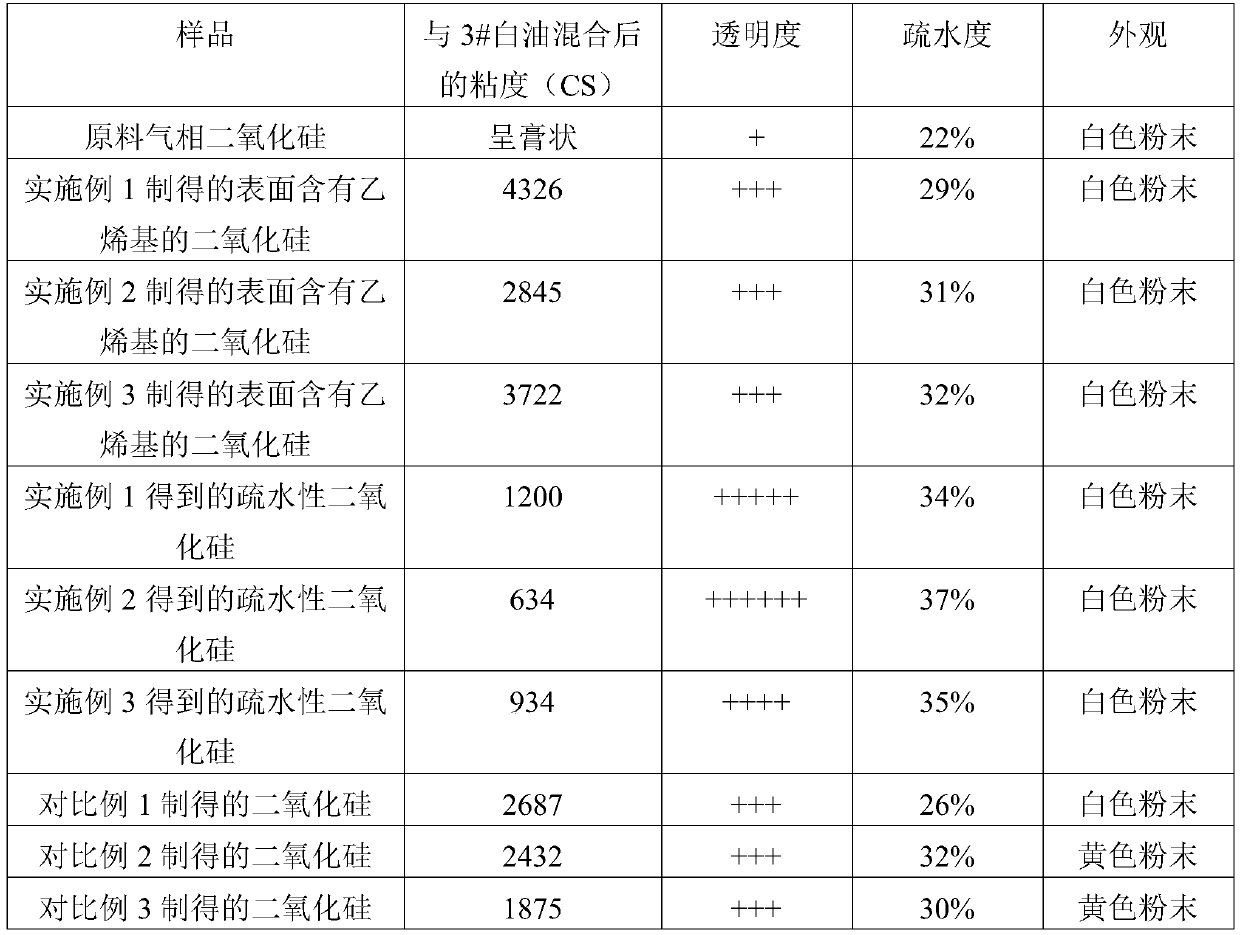

[0043] A method for preparing hydrophobic silicon dioxide by using fumed silicon dioxide, comprising the steps of:

[0044]Send the fumed silica into the processing device, replace the air with nitrogen, add vinyl silicone oil (where c=28, d=2), the amount added is 5% of the mass of the fumed silica, mix well, and react at 300°C for 2h , to obtain silicon dioxide containing vinyl on the surface; cooling to 150°C, adding a mixture of low-viscosity methyl silicone oil (viscosity of 10mPa.s at 25°C) and Castel catalyst (Pt mass content is 2000ppm) In the above-mentioned silica treatment device, mix evenly, under the protection of nitrogen, keep warm at 150°C for 2h, the mass content of Pt in the mixture is 100ppm, and the addition amount of the mixture of methyl silicone oil and castor catalyst is 1% of the mass of fumed silica. 1%; then add tetramethyldisiloxane, keep the temperature at 150°C under the protection of nitrogen, after 4 hours of treatment, vacuum off low molecular ...

Embodiment 2

[0046] A method for preparing hydrophobic silicon dioxide by using fumed silicon dioxide, comprising the steps of:

[0047] Send the fumed silica into the processing device, replace the air with nitrogen, add vinyl silicone oil (where c=40, d=10), the amount added is 15% of the mass of the fumed silica, mix well, and react at 400°C for 6h , to obtain silicon dioxide containing vinyl on the surface; cooling to 200°C, adding a mixture of low-viscosity methyl silicone oil (viscosity at 25°C is 20mPa. In the above-mentioned silica treatment device, mix evenly, under the protection of nitrogen, keep warm at 200°C for 3h, the mass content of Pt in the mixture is 30ppm, and the addition amount of the mixture of methyl silicone oil and Castor catalyst is 5% of the mass of fumed silica. %; then add tetramethyldisiloxane, the amount of tetramethyldisiloxane added is 10% of the mass of fumed silica, and the temperature is kept at 200°C under the protection of nitrogen. After 4 hours of t...

Embodiment 3

[0049] A method for preparing hydrophobic silicon dioxide by using fumed silicon dioxide, comprising the steps of:

[0050] Send the fumed silica into the processing device, replace the air with nitrogen, add vinyl silicone oil (where c=35, d=3), the amount added is 10% of the mass of the fumed silica, mix well, and react at 400°C for 5h , to obtain silicon dioxide containing vinyl on the surface; cooling to 160°C, adding a mixture of low-viscosity methyl silicone oil (viscosity of 16mPa.s at 25°C) and Castel catalyst (Pt mass content is 2000ppm) In the above silicon dioxide treatment device, mix evenly, under the protection of nitrogen, keep warm at 160°C for 2h, the mass content of Pt in the mixture is 50ppm, and the amount of the mixture of methyl silicone oil and castor catalyst is 3% of the mass of fumed silica. %; then add tetramethyldisiloxane, the amount of tetramethyldisiloxane added is 6% of the mass of fumed silica, and the temperature is kept at 180°C under nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com