A liquid tank truck rollover support device and its rack elongation control method

A support device and technology for liquid tank trucks, applied in signal devices, vehicle maintenance, transportation and packaging, etc., can solve problems such as potential safety hazards, large lateral forces, and impact on vehicle passability, so as to ensure self-rotation and reduce drag hazards , to avoid the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

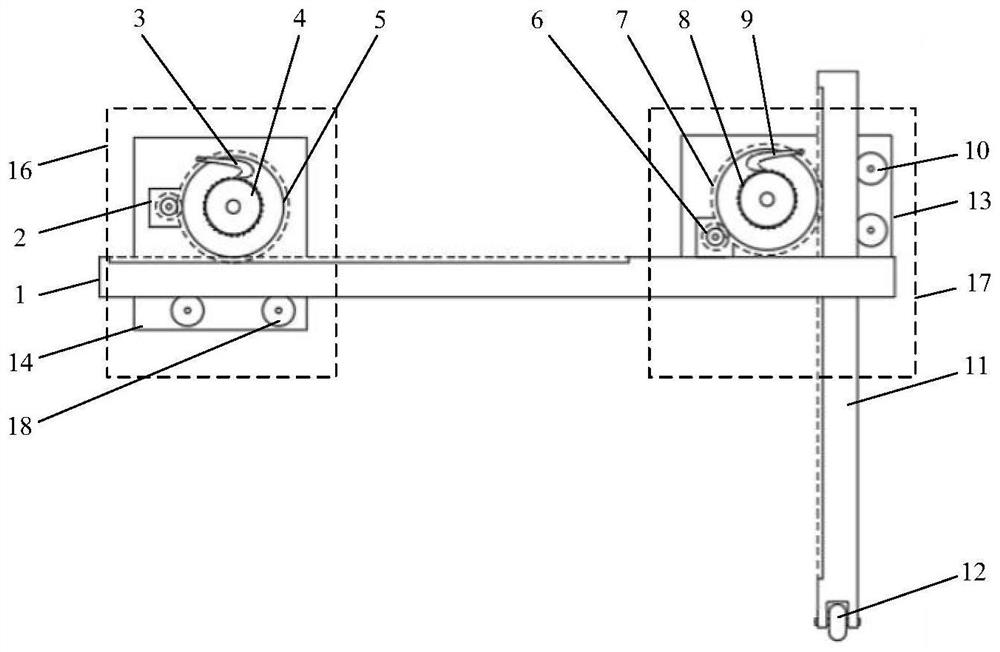

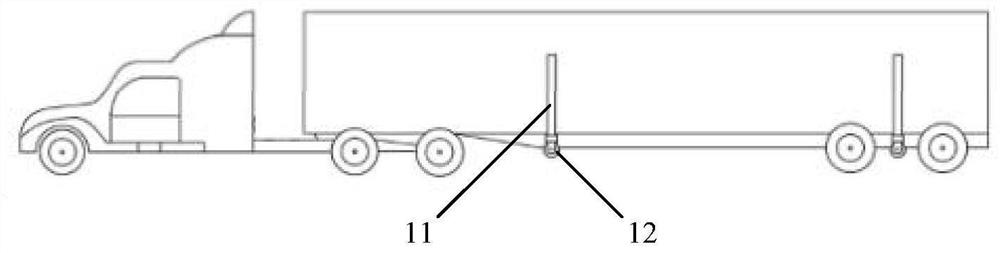

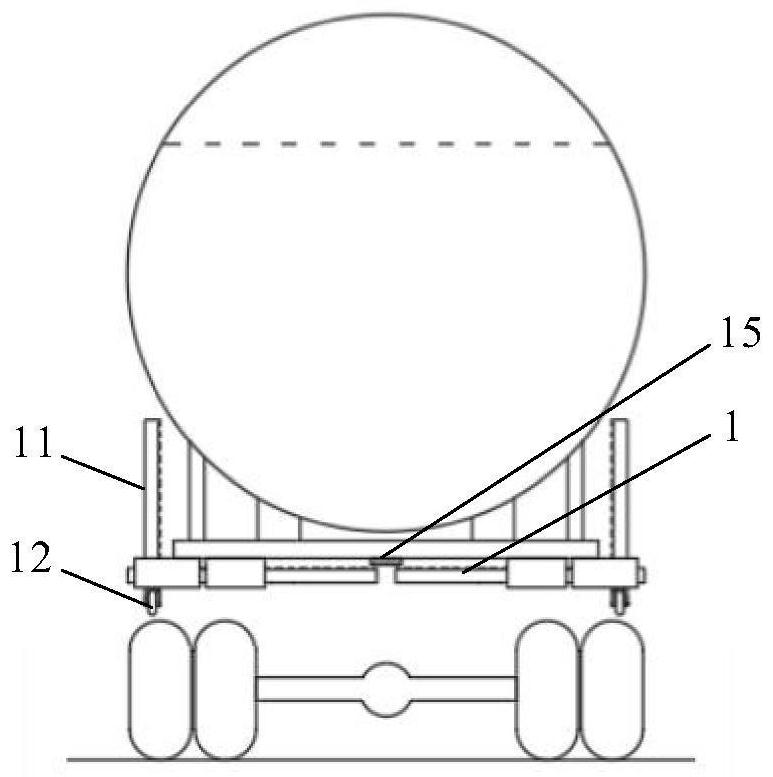

[0025] Such as figure 1 , the first rack 1 meshes with the first gear 5 of the horizontal movement mechanism 16, the second rack 11 meshes with the second gear 7 of the vertical movement mechanism 17, the first gear 5 is driven by the first motor 2, and the first ratchet 4 Rotate coaxially with the first gear 5, the first motor 2, the gear rotation shaft and the first pawl 3 are fixed on the first mounting case 14, the first pawl 3 is locked clockwise, the second rack 11 and the first The two gears 7 mesh, the second gear 7 is driven by the second motor 6, the second ratchet 8 rotates coaxially with the second gear 7, the second motor 6, the gear rotating shaft and the second pawl 9 are fixed on the second installation shell 13, the second pawl 9 is locked counterclockwise, the first rack 1 is fixed with the first auxiliary pulley 18, the second rack 11 is fixed with the second auxiliary pulley 10, and the first auxiliary pulley 18 is fixed at the second On the first installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com