Clamping method of special clamp

A fixture and special technology, applied in the attachment, clamping, positioning device and other directions of the shearing machine, can solve the problems of affecting cutting, hidden dangers, poor clamping effect, etc., to facilitate fixing, improve safety performance, and facilitate flexibility. moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

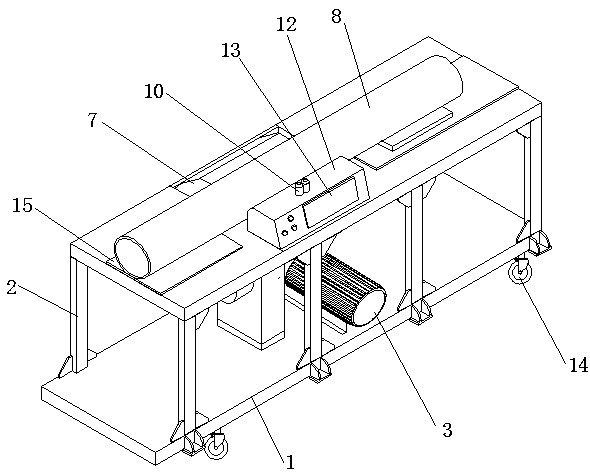

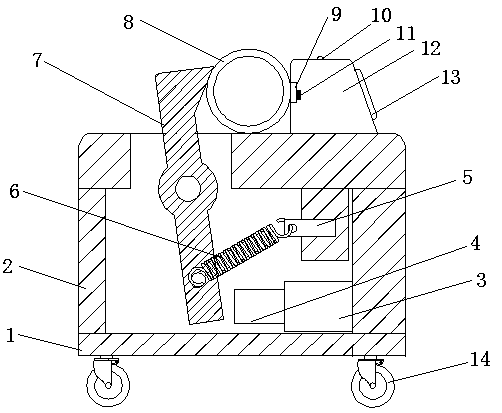

[0044] see figure 1 and figure 2 , a special fixture, including a fixture base 1 with a fixture bracket 2 installed on the upper end, a clamping cylinder 3 connected to the side end of the fixture bracket 2, a piston rod 4 connected to the power output end of the clamping cylinder 3, and a piston rod 4 connected to the inner end of the fixture bracket 2 There is a fixed block 5, the inside of the fixture bracket 2 is provided with a movable pressure plate 7, the middle part of the movable pressure plate 7 is rotatably connected with a rotating shaft, the end of the rotating shaft is fixedly connected with the inner end of the fixture bracket 2, the upper end of the movable pressure plate 7 extends to the upper side of the fixture bracket 2, and the movable pressure plate A tension spring 6 is connected between the lower end of the 7 and the end of the fixed block 5, a fixed pressing block 12 is connected to the upper end of the clamp bracket 2, a steel pipe 8 is arranged betw...

Embodiment 2

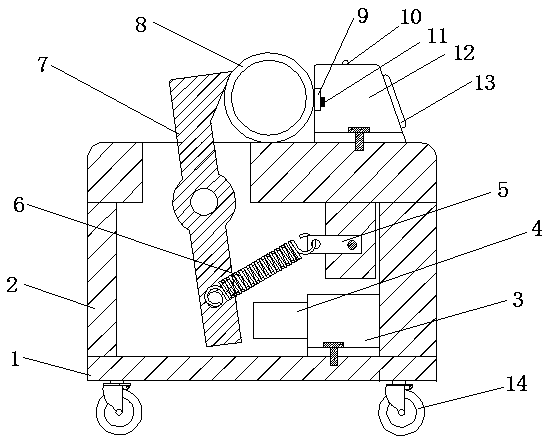

[0059] see image 3 , a special fixture, including a fixture base 1 with a fixture bracket 2 installed on the upper end, a clamping cylinder 3 installed on the side end of the fixture bracket 2 through screws, and a piston rod 4 connected to the power output end of the clamping cylinder 3, inside the fixture bracket 2 The fixed block 5 is installed on the end by screws, and the inside of the fixture bracket 2 is provided with a movable pressure plate 7, and the middle part of the movable pressure plate 7 is rotatably connected with a rotating shaft. On the upper side, a tension spring 6 is connected between the lower end of the movable pressing plate 7 and the end of the fixed block 5, and a fixed pressing block 12 is installed on the upper end of the fixture bracket 2 through screws, and a steel pipe 8 is arranged between the fixed pressing block 12 and the movable pressing plate 7, and fixed The main controller is connected to the briquetting block 12, and the side of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com